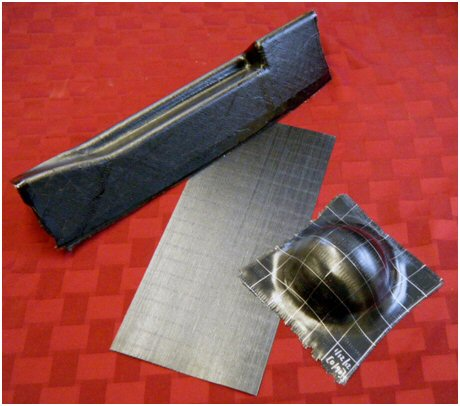

According to Pepin Associates, Greenville, Maine, USA, DiscoTape has shown promise in the formation of composite parts with complex curvatures normally precluding the use of unitape without cutting and darting.

The material can be made with glass or carbon fibre prepregged with epoxy resins or thermoplastics. Variations of fibre lengths and segmentation patterns have been investigated to optimise DiscoTape for a variety of applications.

Mechanical properties

Pepin Associates have conducted research on DiscoTape to ascertain its mechanical properties as compared to continuous tape, determine its forming limits and evaluate its use for composite structures such as keels, frames, fairings and radomes.

Mechanical testing shows that while there is a knockdown of 0° tensile strength in the discontinuous unitape, interlaminar shear and in-plane shear remain relatively consistent with those properties of continuous unitape.

Tensile modulus is also close to continuous reinforcement values.

This would allow use of DiscoTape in structures whose designs are stiffness driven such as bead stiffened shear panels. The ability of the discontinuous unitape to stretch and form complex parts could enable manufacturers to use unitape where it hasn’t been used in the past.

Radomes

One possible application for DiscoTape is radomes. These fibe reinforced composite structures are used to protect radar equipment on aircraft and rotorcraft during flight. The extreme environments these structures must endure during all aspects of flight, especially for military platforms, require strength and durability. However, these same structures must be as close to transparent as possible in allowing radar frequencies to penetrate the structure.

Pepin Associates has completed a study on the formability and transmissivity of glass DiscoTape, applicable for use in radome manufacture. Tests have shown that discontinuity does not always affect transmissivity of the radar signal.

It was found that the discontinuity may interfere with the signal at X-band frequencies. In the event the material is showing signal loss, the length of DiscoTape segments can be altered, allowing the fabricator to ‘tune’ the material as needed.

The research showed no appreciable effect on the material transparency for the Q-band frequency.

These results are promising because radome shapes are as variable as the aircraft on which they are mounted. Aircraft and rotorcraft radomes all have a cone or hemispherical component which is a challenge to fabricate with composite materials. Forming such complex curvatures with continuous, unidirectional tape is a challenge due to wrinkling of the material. Wrinkles can degrade both the radar signal and radome structural integrity. Applying unidirectional reinforcement tape to fabricate these parts without wrinkles is difficult and time consuming: DiscoTape could allow the formation of these shapes without wrinkling.

| We believe the forming capabilities of DiscoTape will provide a significant manufacturing advantage in terms of time savings and reduction of scrap material versus the use of continuous unitape. There is more development work to be done, but our initial results are very promising. |

| John Pepin, President, Pepin Associates |

DiscoTape has the potential to be used on many other structures ranging from wind blades to medical imaging equipment to structures for aircraft and rotorcraft. Pepin Associates is seeking to evaluate DiscoTape applications for hard-to-form parts and structures commonly made with continuous unitape.

Thermoplastic parts

The ability of this discontinuous unitape to form complex parts has drawn the attention of Tom Campbell, Applications Engineer at Fiberforge Inc.

Colorado-based Fiberforge has developed a patented manufacturing process for continuous fibre reinforced thermoplastic parts. Campbell is evaluating a thermoplastic version of DiscoTape for possible use in aerospace applications.

“Fiberforge sees significant potential in the DiscoTape process in forming complex parts from thermoplastic composites," says Campbell. "The possibility of discontinuous forming behaviour in a nearly continuous material is very intriguing and we look forward to exploring the possibilities and bounds of this new material format.”