The ThermoPlastic Composites Research Center (TPRC), based in the Netherlands, says that it has successfully closed a two-year collaborative project on the overmolding of thermoplastic composites.

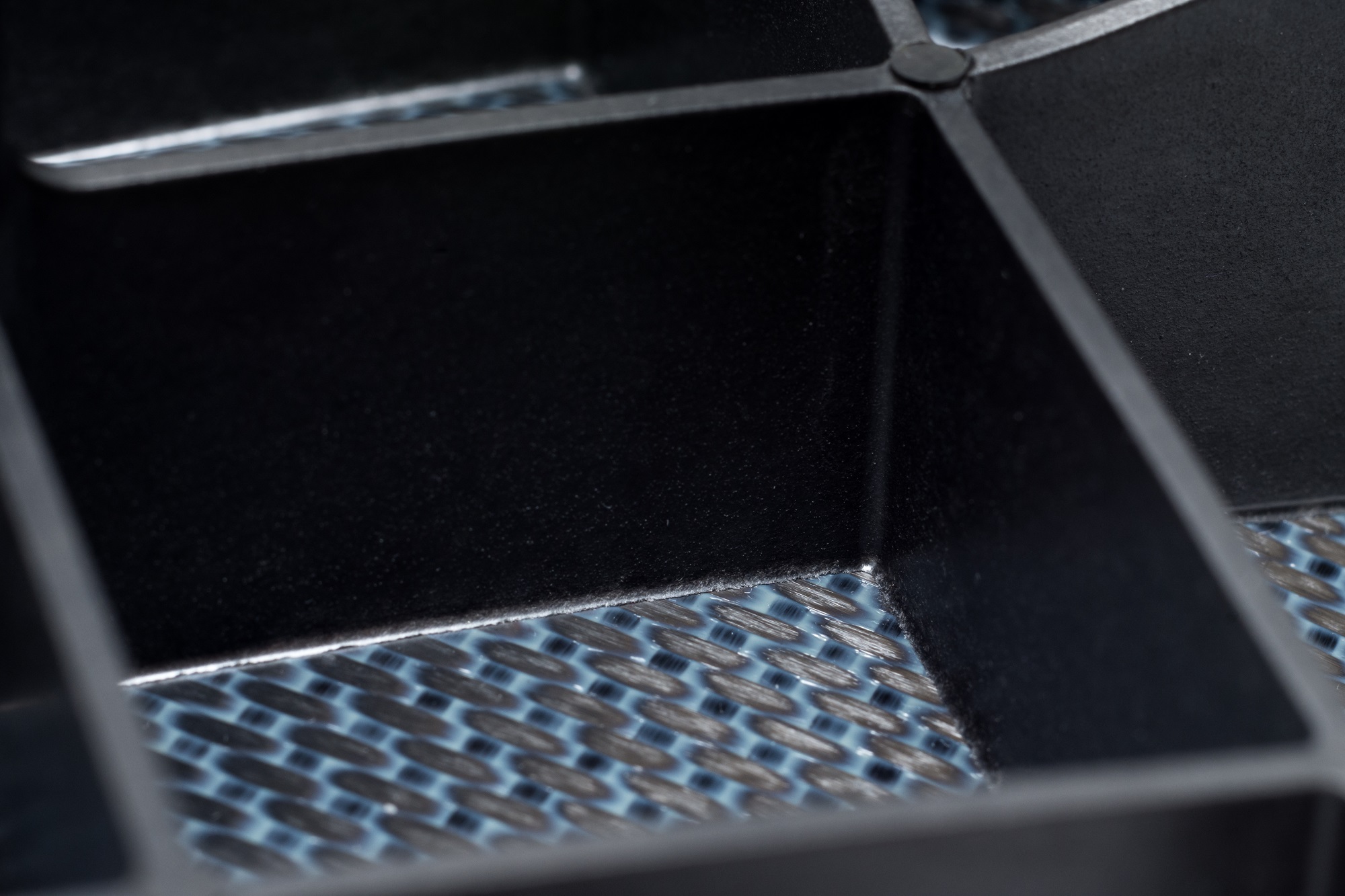

The center has designed and manufactured an advanced demonstrator part following a two year collaboration between TPRC, its members and companies contributing from different areas of expertise. The part features a typical grid stiffened panel that can be found in larger numbers in aerostructure applications. The stiffness and strength performance combined with extreme dimensional accuracy can put high demands on the manufacturing process.

The thermoplastic composite insert was press formed using TenCate Cetex TC1225 engineered C/PAEK and subsequently overmolded with Victrex PEEK90HMF40. The relatively low melting temperature of the composite material enabled overmolding with PEEK at moderate insert temperature. The heat of the injected polymer was used to melt the surface of the solid insert upon contact, making the material combination extremely suitable for a two-step overmolding process, according to the TPRC.

Process design tools

During the overmolding process, a continuous fiber reinforced shell with relatively simple geometry was stiffened with a complex injection molded grid. However, tool design for injection molding is complex, and becomes even more challenging when the process is combined with continuous fiber reinforced thermoplastics, the reseach center said. Numerical process design tools are indispensable for the composite engineer who more and more needs to take manufacturability into account in an early stage. TPRC researchers Mark Bouwman, Thijs Donderwinkel and Jeroen Houwers worked on the experimental validation and modeling of the mechanisms underlying the overmolding process. They translated these to numerical models using a thermoforming software package (AniForm) combined with Autodesk Moldflow to predict interface strength and warpage caused by process-induced residual stresses.

‘We have been very impressed with the quality of composites research at TPRC,’ said Franco Costa, senior research leader at Autodesk Moldflow. ‘The team at TPRC has demonstrated a great mix of practical process knowledge and a robust approach to modelling techniques and model development. The TPRC has also been very successful in bringing together into a collaborative project a broad range of companies which have each contributed from their own domain either equipment, materials expertise, process knowledge, modelling knowledge and software modelling.’

This story uses material from the TPRC, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.