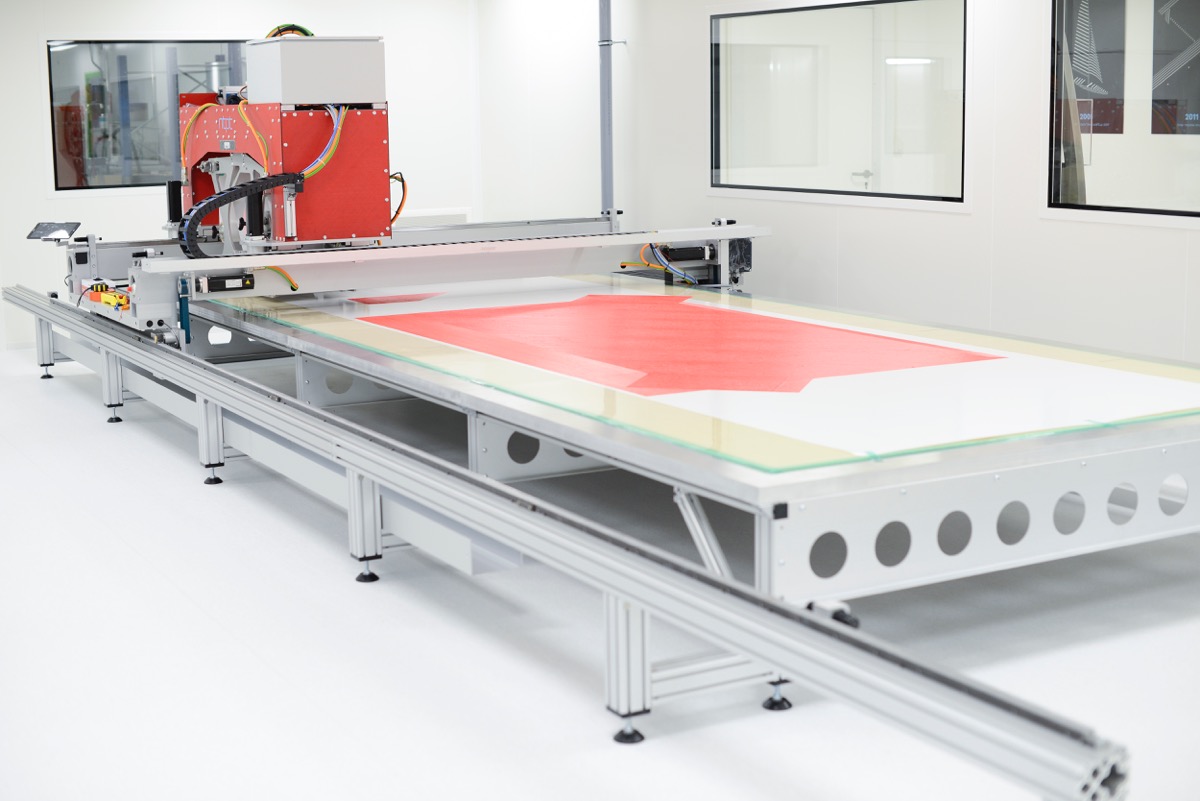

Prepreg specialist NTPT has opened new laboratory facilities and a 300 m2 cleanroom production area at its headquarters in Renens, Switzerland. This development is part of the company’s collaboration with watchmaker GMV-Richard Mille and includes the exclusive supply of NTPT’s Thin Ply materials for horology, jewellery and writing instrument designs.

According to the company, the production facility is designed to make quartz and other non-carbon fiber materials and features antistatic bars, a suction unit and a new creel system, to prevent contamination and to ensure optimum quality output. A new 1 m3 autoclave has a maximum pressure of 10 bars and maximum temperature of 260°C. The facility can reportedly produce 7500 km of fiber and more than 7 tonnes of Thin Ply composites annually.

The R&D equipment includes differential scanning calorimetry (DSC), dynamic mechanical thermal analysis (DMTA), viscometer, microscopes, and an instron mechanical bench test.

NTPT says that the cleanroom could also be used for other applications that require a high level of contamination-free composite material.

This story is reprinted from material from NTPT, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.