"The new GEMINI system saves several million dollars in equipment, infrastructure and labour cost traditionally needed for two separate systems, making it ideal for aerospace tier suppliers who require cost economy and flexible capabilities," claims Robert Harper, Director of Sales for MAG's composite products.

MAG says the GEMINI system is ideal for precision production of fuselage sections, panels, cowls, ducts and nozzle cones for commercial, military and space vehicles, including parts that make use of honeycomb core materials.

The first GEMINI system has been purchased by Alliant Techsystems. It will be installed at ATK's Iuka, Mississippi, USA, facility. With this order, ATK now has eight MAG fibre placement systems installed at its plants.

The order includes MAG's modular ACES(R) software (Advanced Composites Environment Suite) programming and simulation system for tape laying and fibre placement.

Ideal for aerospace suppliers

"For a fraction of the cost of a full tape laying system, aerospace composite part suppliers can now add tape laying capability on a fibre placement machine or vice versa, saving millions on machinery, plant infrastructure, labor and training otherwise needed for two machines," says Randy Kappesser, Vice President MAG Composites.

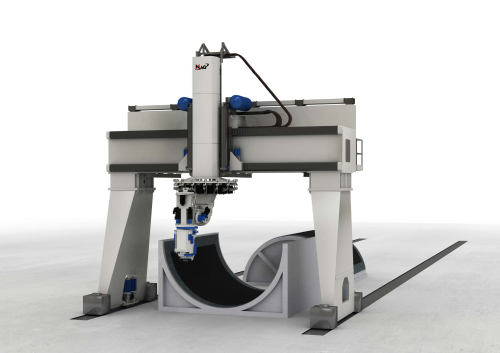

"The system makes it possible for fabricators to consider combining composite tape and fibre in the same part, and it certainly can improve the cost structure for the industry by maximising equipment utilisation and facilitating use of lower cost tape to a greater extent. Even the modular vertical gantry design is engineered with flexibility in mind. It can be configured for multiple work zones or extremely long parts, while providing excellent workzone access for head changing and tool loading."

MAG and Forest Line

The GEMINI system utilises MAG's VIPER® automated fibre placement (AFP) head and CHARGER™ tape laying head, or the Forest Line ATLAS automated tape laying (ATL) heads.

"The ability to dock an ATLAS head, which utilises pre-cut roll dispensing from MAG Forest Line's Access system, is another productivity advantage of the GEMINI Docking Head system," says Kappesser.

Head docking cradles outside the workzone allow efficient offline setup or maintenance of heads while the machine can continue to produce parts. Head changing requires about two minutes.

The gantry design of the system accommodates both fixed floor-mounted or rotation type tooling in Outer Mold Line (OML) or Inner Mold Line (IML) configurations. The gantry is modular and available in various widths, as well as with X-axis rails on top of the floor or in-floor. It can be ordered in any length required, in addition to carrying multiple gantries. A new wireless control pendant gives the operator greater freedom and convenience in working with the system.

The AFP heads handle tow widths of 3.2, 6.4 and 12.7 mm (0.125, 0.25, 0.5 inches), producing fibre band widths up to 203.3 mm (8 inches). They provide independent control over feed, clamp, cut and re-start for up to 16 individual tows of composite prepreg slit tape, allowing automated 'on-the-fly' adjustment of the fibre band width, controlled placement of fibres around changing contours, and precise configuration of openings.

The system allows wrinkle-free, near-net-shape lay-up of enclosed and deeply contoured structures and concave/convex surfaces.

Tape laying

MAG's CHARGER tape laying head deposits carbon/epoxy tape at speeds up to 100 m/min (4000 ipm) while achieving aerospace grade placement accuracies on complex contours. It applies 75, 150 or 300 mm (3, 6 or 12 inch) carbon/epoxy tape with any orientation and number of plies, ensuring consistent quality, part shape, thickness and strength. The head allows fast, simple side loading of tape rolls up to 300 mm (12 inches) wide and 650 mm (25.6 inches) diameter.

Common hardware permits lay-up of 150 mm (6 inch) and 300 mm (12 inch) wide tape with minimal changeover time. The advanced head design also features integrated ultrasonic laminate cutting, cutter depth-setting assistance, and dockable inkjet marking for maximum system flexibility and performance. An infrared heating system provides faster response and greater precision than air heating, and maximises lay-down rates with a wider variety of materials.

The Forest Line ATLAS tape head has the ability to dispense pre-cut rolls of material that were made on the Forest Line Access system. Along with the pre-cut roll of tape, the ATLAS head can also simultaneously carry bulk rolls of material 150 or 300 mm (6 or 12 inches) wide, allowing a part to be laid using pre-cut rolls of material and material from the bulk rolls of tape.