The composite laptop cover parts were made with polyethylene terephthalate (PET), polyamide (PA) and acrylonitrile butadiene styrene/ polycarbonate (ABS/PC) reinforced with carbon fibre.

RocTool’s Cage System® technology heats and cools the mould surface “practically instantly.” In association with PMC’s CFRT® (continuous fibre reinforced thermoplastic) materials, RocTool of Le Bourget du Lac, France, says it is able to produce the composite laptop covers in approximately two minutes.

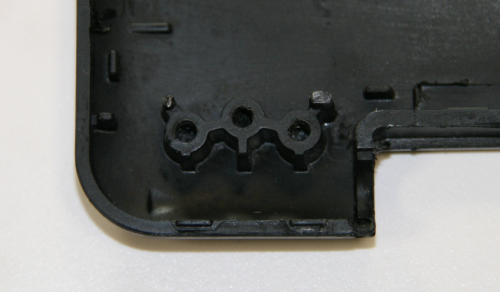

The use of CFRT material allows the production of thinner parts and offers a 15-20% weight reduction compared with parts made using magnesium. The carbon composite parts are said to have good surface quality and impact resistance.

Tom Smith, Chief Executive Officer at PMC Camarillo, California, USA, says: “The Cage System technology provides a critical missing link in making high volume, complex CFRT parts… These technologies provide for advanced composite performance approaching the detail and speed of injection moulding. The processes are also amenable to a high level of automation.”