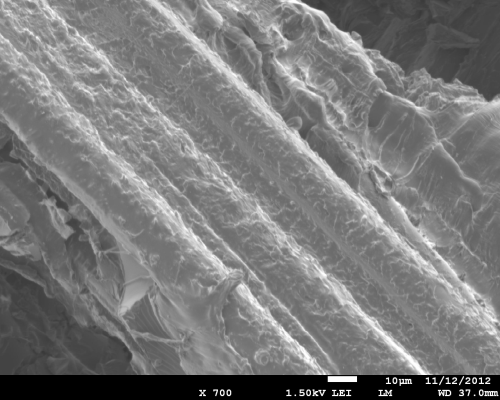

This technology has enabled the development of products such as StarRov® RXN886 direct roving, which is ready for testing for use in the in-mould caprolactam polymerisation process.

StarRov RXN 886 is said to maximise glass-matrix bonding, resulting in improvements in strength, multiaxial impact, ageing performance and dimensional stability of polyamide 6 (PA 6) based structural composites.

JM says the product is ready for testing by customers in a variety of processes, including thermoplastic (TP)-RTM, TP-RIM, TP-pultrusion, and TP-filament winding.

Chopped strands for food contact

Johns Manville has also introduced two chopped glass strand materials, ThermoFlow® 674 and 601, for reinforcement of polyamide and PBT/PET engineered thermoplastics, respectively.

These materials were developed to reinforce engineered plastics in compliance with EU regulation No. 10/2011 of 14 January 2011 on plastic materials and articles intended to come into contact with food. The ThermoFlow 674 and 601 chopped strands, as well as ThermoFlow® 636 for polypropylene, enable engineers to enhance the performance of thermoplastic materials and articles intended to come into contact with food.

| With our recent expansion of the Trnava, Slovakia facility, we are in a great position to support the growth agenda of our customers. (See JM expands glass fibre production at Slovakia plant.) |

| Enno Henze, vice president and general manager, JM Engineered Products Europe/Asia |

“Over the last couple of years we have focused our research and development activities on enhancing our product portfolio of chopped strands for the reinforcement of thermoplastic polymers," explains Enno Henze, vice president and general manager for JM Engineered Products Europe/Asia.

"And the efforts are truly paying off. Our ThermoFlow product line enables our customers to engineer reinforced polymer compounds with outstanding mechanical performance and chemical resistance whether they are based on polyamides, polyesters, polypropylene or speciality polymers."