Sigma Engineering and other companies say that they have begun full speed production of injection molded face masks made of liquid silicone rubber (LSR).

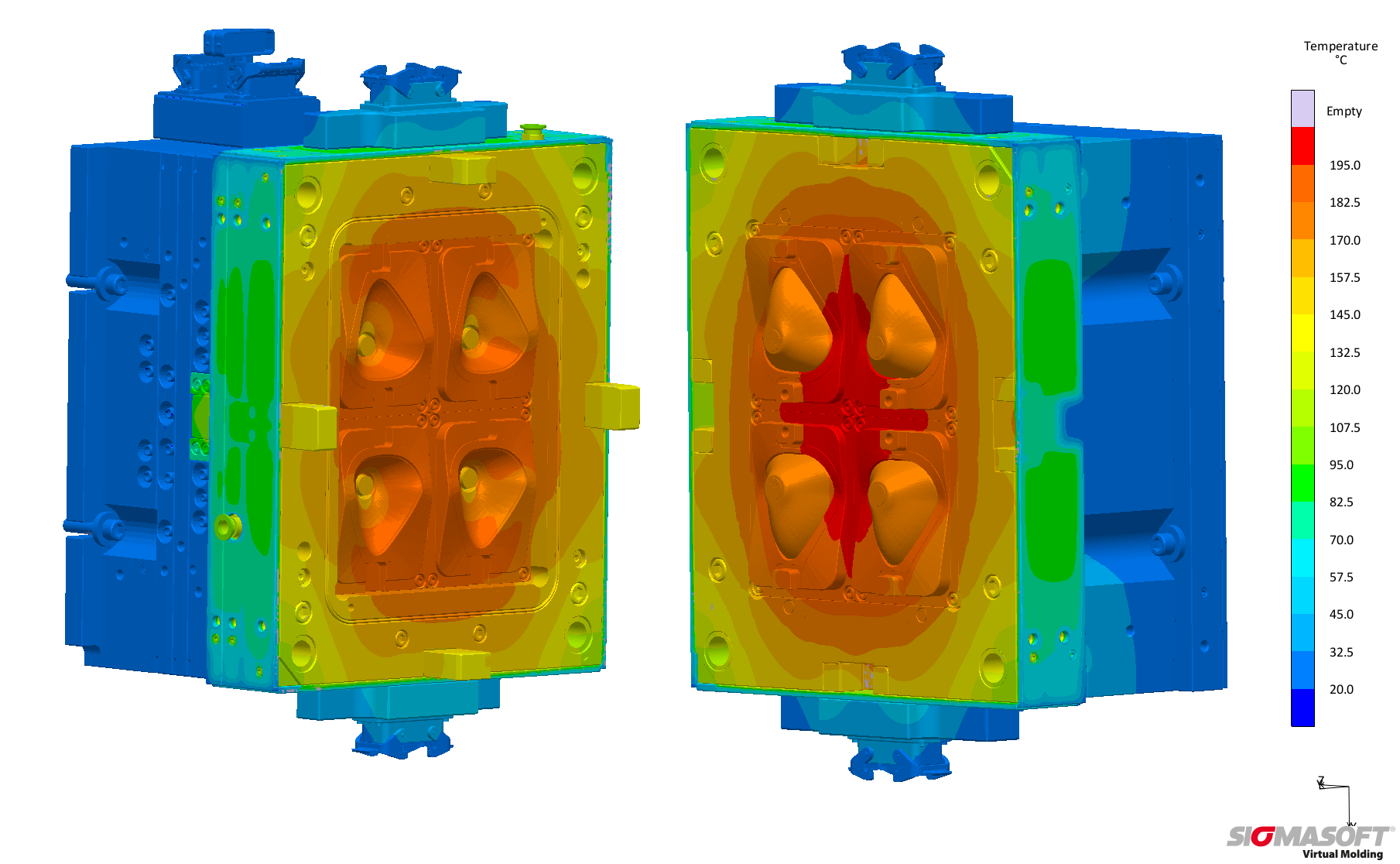

Sigmasoft said that its Virtual Molding software was used to determine and optimize injection points, pressure requirements, temperature distribution, air entrapment, and the crosslinking of the LSR material.

‘We noticed a high demand for protective masks from the public as well as from our own employees, which made this project-cooperation highly welcome,’ said Thomas Klein, MD of Sigma.

‘We examined a lot of different factors,’ said Tobias Sonntag, project engineer. ‘But the focus was on component quality, optical properties and, of course, the safety of the user that comes with a perfect component free of air entrapments or other defects. But also, a fast and resource-saving process design was very important to us.’

This story uses material from Sigma, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.