SGL Group and German engineering company Bertrandt have developed a new design idea for the interior structures of automotive vehicles.

The ‘Carbon Carrier’ design uses lightweight fiber compounds to offer new configuration and design options for vehicle interiors.

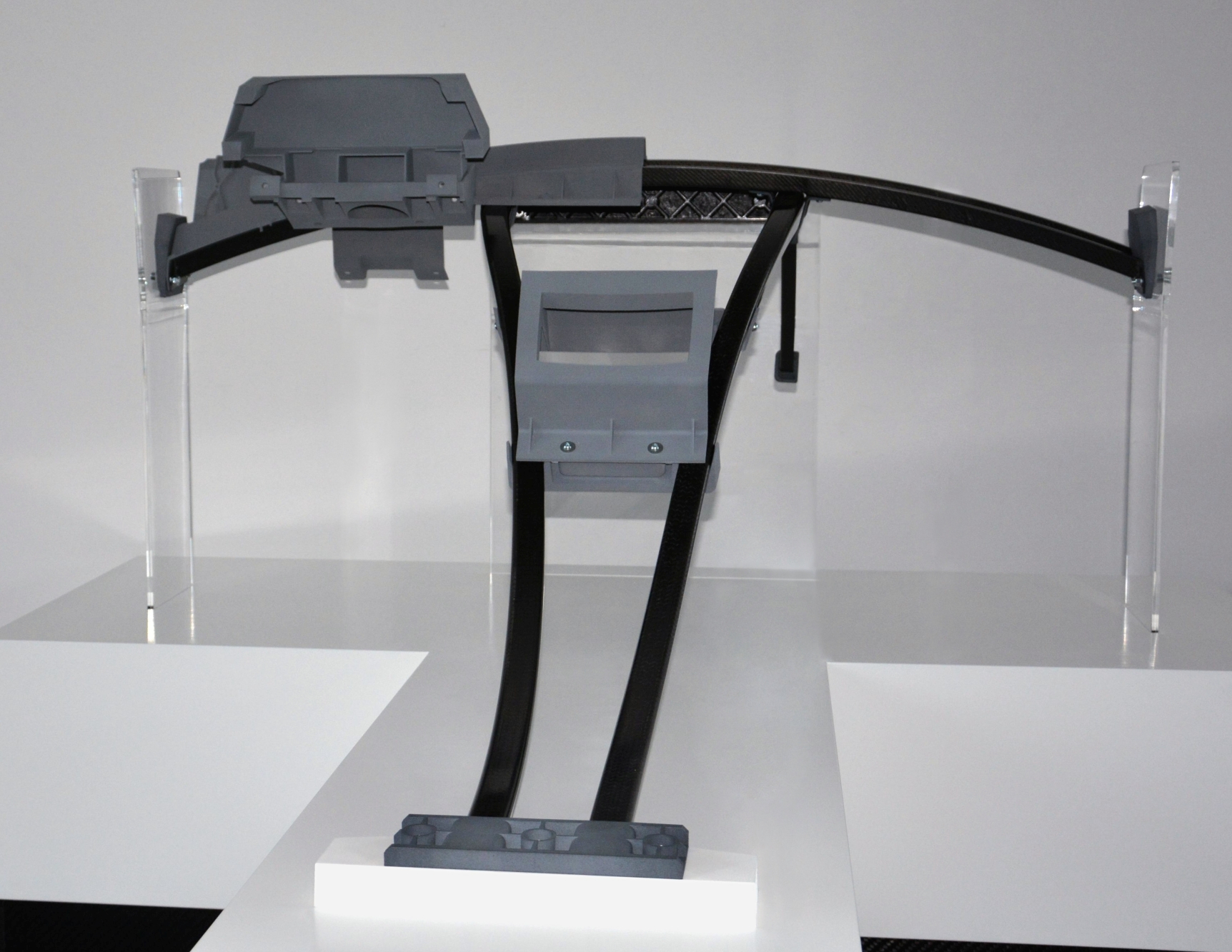

It is based on an initial body draft created at Bertrandt which could be used for the front vehicle interior of a convertible or coupè with electric drive. The model includes all major function and trim components of a conventional instrument panel and has a design which could help engineers visualize central load paths and carbon fiber reinforced plastics elements for drivers. Structural components were also redesigned, the companies say.

‘While designing the Carbon Carrier, we made sure that the components, technologies and assembly concepts used, were ready for large-scale production either now or in the near future,’ said Michael Hage, head of body development at Bertrandt. ‘For electric vehicles in particular, reduced weight means a greater range.’

The companies aimed to find an improved configuration of matrix and fiber material, fiber length, portion and orientation, layer structure and process technology, as well as an improved material mix and production technology. ‘The combined expertise of Bertrandt and SGL Group along the entire product development process was incorporated into the Carbon Carrier – from the concept phase, to design and automated large-scale production,’ said Dr Andreas Erber, head of the lightweight and application center, SGL.

This story is reprinted from material from SGL, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.