"We are one of the pioneers in the automotive industry for large-scale production of carbon parts, thanks to our innovative production process," says Han Hendriks, vice president of global product development, interiors at Johnson Controls Automotive Experience.

“We are pleased to be able to transfer that technology for use in vehicle exteriors.”

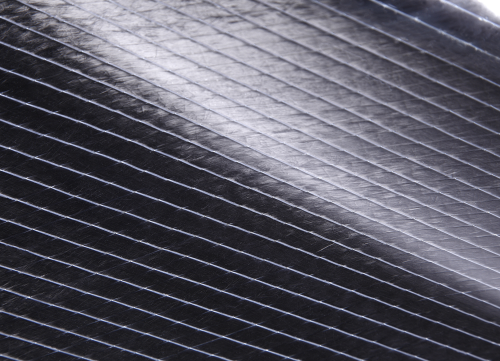

The new process is based on a wet press process which Johnson Controls has used since 2003 to produce wood fibre components for vehicle interiors. In the newly adapted process, a carbon fibre mat pre-moistened with resin is placed between the forming tools and then pressed. During the pressing cycle, the excess resin leaks onto the edge of the mould. This provides a very high fibre density in the body parts.

Johnson Controls says it is already supplying a well-known automotive manufacturer with carbon components.

Johnson Controls is a global leader in automotive seating, overhead systems, door and instrument panels, and interior electronics. It has 240 locations worldwide and supplies approximately 50 million cars per year. |