In 2004, the St Nazaire and estuary regional urban community (CARENE - Communauté d’Agglomération de la Region Nazairienne et de l’Estuaire) launched a programme to reconfigure the community’s waste water discharge and treatment system. The aim is to establish a consistent system with new, modern equipment to serve the 116 000 inhabitants of this area of France.

The project includes the erection of two new waste water treatment plants which are expected to go into operation in 2012.

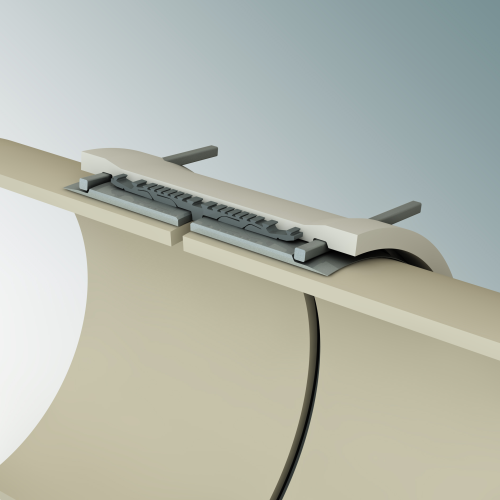

The design of the hydraulic system includes pipelines conveying the effluents from the old waste water treatment plants and discharge units over long distances to the two new facilities. This scheme demands a pressure line with mechanical strength and high resistance to chemical attack. A significant proportion of planned network also has to pass through difficult ground including marshlands and brackish environments. Casting thrust blocks in the middle of salty marshland and urban environment was out of the question. The CARENE therefore selected a restrained PN 10 glass fibre reinforced plastic (GRP) pipe system, ensuring short installation times and structural longevity.

The restrained GRP pipe system was supplied by HOBAS France.

“HOBAS CC-GRP Pipe Systems are perfect for this project as they are fit for all types of terrain and perfectly follow the winding route," reports Michel Sokolowski, Regional Sales Manager at HOBAS France.

The new network connecting to the future treatment plant in the west of St Nazaire involves more than 20 km of pipe and further 8.4 km are used to meet the second plant located in the east. Since 2007, 24.5 km HOBAS centrifugally cast GRP (CC-GRP) pipes ranging from DN 200 to DN 500 have been laid in the ground by means of open trenches.

The project is scheduled for completion in two years time.