A research team at the Georgia Institute of Technology has developed a novel technique that it says can improve the strength and modulus of carbon fibers. This alternative approach is based on a new way to spin polyacrylonitrile (PAN), an organic polymer resin used to make carbon fibers.

‘By using a gel-spinning technique to process polyacrylonitrile copolymer into carbon fibers, we have developed next generation carbon fibers that exhibit a combination of strength and modulus not seen previously with the conventional solution-spun method,’ said Satish Kumar, a professor in the Georgia Tech School of Materials Science and Engineering who is leading the project. ‘In addition, our work shows that the gel-spinning approach provides a pathway for even greater improvements.’

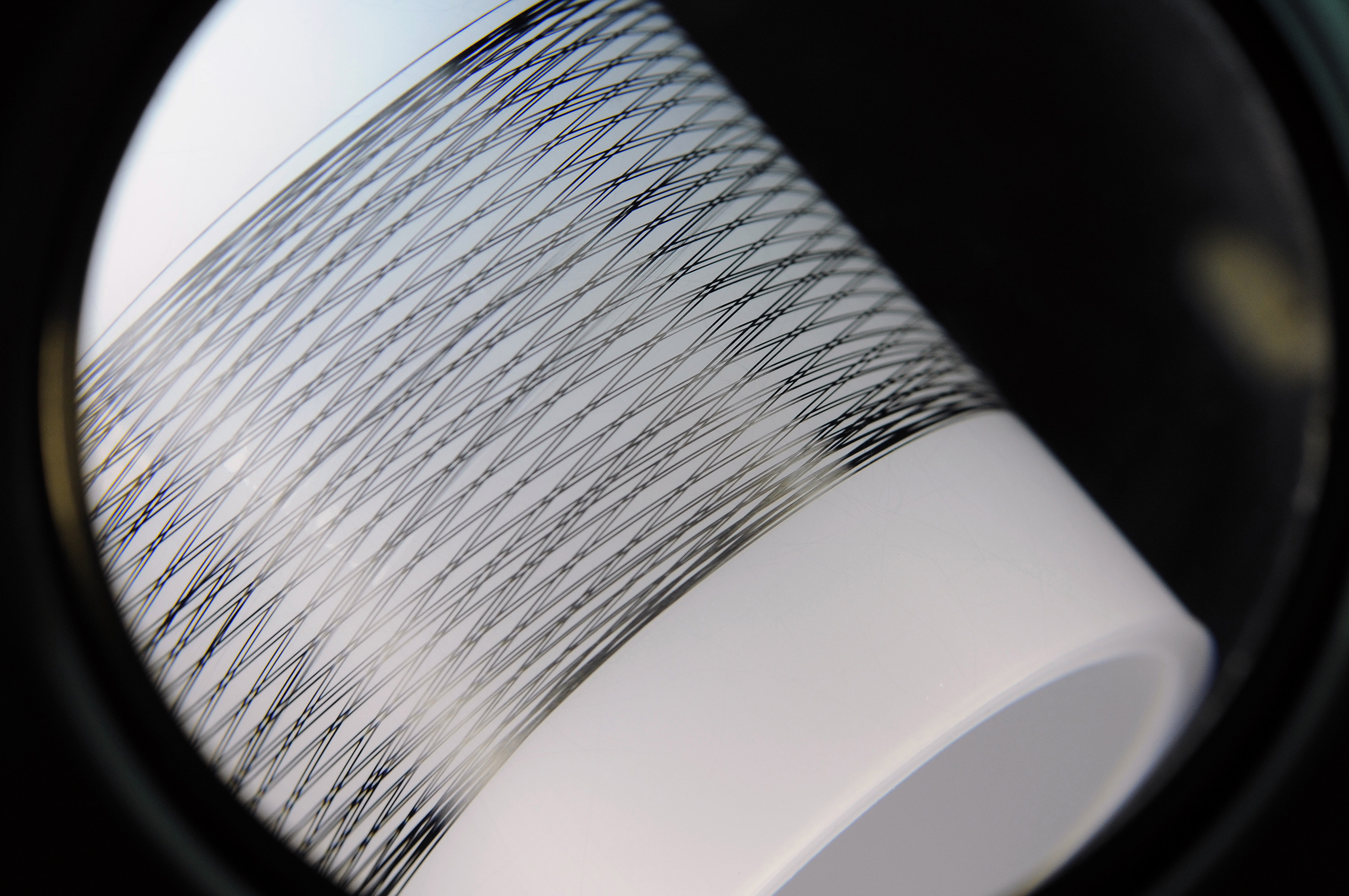

In gel-spinning, the solution is first converted to a gel, which binds polymer chains together and produces robust inter-chain forces that increase tensile strength. Gel-spinning also increases directional orientation of fibers, which also augments strength. This contrasts with conventional solution spinning where PAN co-polymer solution is directly converted to a solid fiber without the intermediate gel state and can produce less robust material.

The gel-spun carbon fiber produced by Kumar’s team was tested at 5.5 to 5.8 gigapascals (GPa) and had a tensile modulus in the 354-375 GPa range. ‘This is the highest combination of strength and modulus for any continuous fiber reported to-date,’ Kumar claimed. At short gauge length, fiber tensile strength was measured as high as 12.1 GPa, which is the highest tensile-strength value ever reported for a PAN-based carbon fiber.

Fewer imperfections

According to Kumar, the internal structure of the gel-spun carbon fibers measured at the nanoscale showed fewer imperfections than commercial carbon fibers, such as IM7. Specifically, the gel-spun fibers display a lower degree of polymer-chain entanglements than those produced by solution spinning. This smaller number of entanglements results from the fact that gel-spinning uses lower concentrations of polymer than solution-spinning methods.

Kumar and his team converted the gel-spun polymer mix into carbon fibers via a selective treatment process called pyrolysis, in which the spun polymer is gradually subjected to both heat and stretching. This technique eliminates large quantities of hydrogen, oxygen, and nitrogen from the polymer, leaving mostly strength-increasing carbon.

‘It’s important to remember that the current performance of solution-spun PAN-based carbon fibers has been achieved after many years of material and process optimization – yet very limited material and process optimization studies have been carried out to date on the gel-spun PAN fiber,’ Kumar said. ‘In the future, we believe that materials and process optimization, enhanced fiber circularity, and increased solution homogeneity will further increase the strength and modulus of the gel--spinning method.’

The work is part of a four-year, US$9.8 million project sponsored by the Defense Advanced Research Projects Agency (DARPA) to improve the strength of carbon fiber materials. The research was reported recently in the journal Carbon.

This story is reprinted from material from Georgia Tech, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.