Using HiPer-tex high performance glass fibre from 3B, GASTANK Sweden AB is able to produce a cylinder that meets the United Nations ECE R110 regulation governing the use of type IV high pressure cylinders containing CNG for motor vehicles.

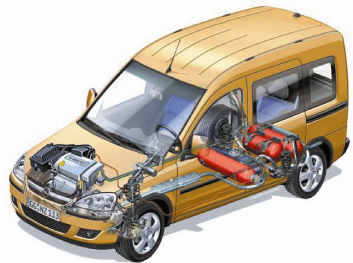

According to 3B, CNG has risen strongly in popularity over the last few years and more than 11 million vehicles worldwide benefit from this fuel. Currently, high pressure tanks are made of steel which are extremely heavy, adding significantly to the weight of the vehicle. Lighter weight carbon fibre composites can be used but component cost is often prohibitive for most vehicles.

“HiPer-tex™ high performance fibres enable the gap between heavy weight steel and high cost, carbon fibre composites to be bridged due to its ability to deliver a comprehensive package of properties economically," says Professor Kurt Berglund, President of GASTANK Sweden AB based in Piteå, Sweden. "This makes lighter weight, composite CNG tanks available to a much wider range of customers. This will consequently have an extremely positive impact on energy consumption and CO2 emissions as CNG continues to grow as a propulsion fuel.”

CNG as fuel system is fitted to approximately 2 million cars per year with as many as 4 tanks installed per vehicle. Some OEMs offer CNG as an option, however many vehicles are retro-fitted and the use of CNG is expected to grow at 18% per year.