Researchers at the Georgia Institute of Technology have received funding to investigate ways to join and repair composite and hybrid structures.

According to the Institute’s Center for Composite and Hybrid Materials Interfacing (CHMI), it can be difficult to model how composites may degrade and fail during use. As well as this, impact damage for example on aircraft may not be visible, making it harder to detect than damage to metallic structures.

It can also be expensive and time-consuming to repair the materials, the Institute said. For example, a bird striking a plane can damage a composite structure on the wing of the aircraft. The airline company or maintenance provider must then deploy specialized, expensive patches – often to remote locations. If the aircraft has to be grounded, it can cost an airline around US$100,000 or more in lost revenue.

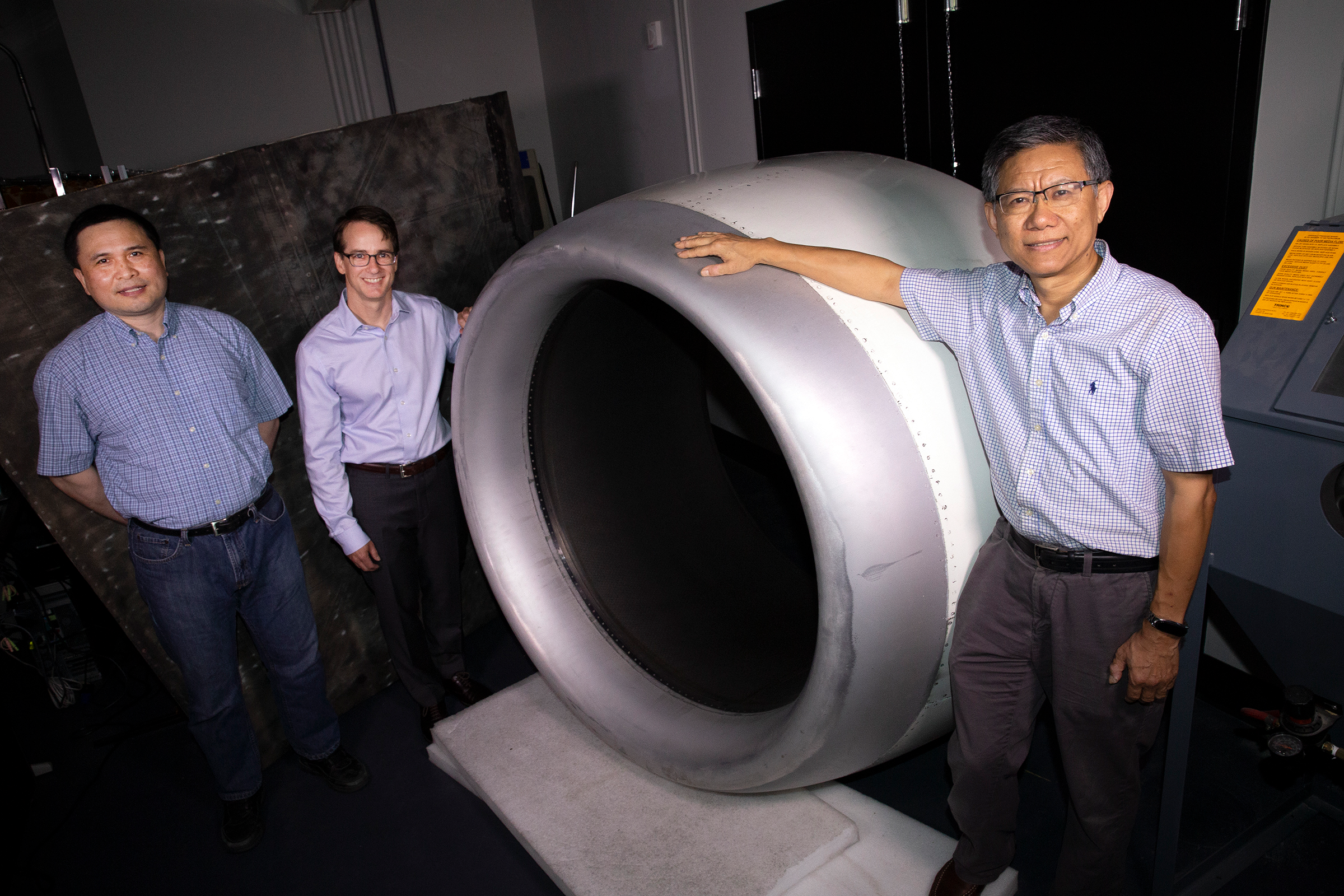

The research, which incorporates teams from Georgia Tech, Oakland University, and the University of Tennessee, Knoxville (UT) will use data analytics and digital techniques to help improve and speed up composite repair, focusing on the interface between composite, metallic and other electronic materials.

We hope to reduce by 50% the overall cost, cycle time and variation of these processes in the next 10 years,’ said CHMI director Chuck Zhang.

This story uses material from Georgia Tech, with editorial changes made by Materials Today.