Aerospace engineers at MIT have developed a carbon nanotube (CNT) film that can heat and solidify a composite without the need for massive ovens.

When connected to an electrical power source, and wrapped over a multilayer polymer composite, the heated film stimulates the polymer to solidify.

Composite materials used in aircraft wings and fuselages are usually manufactured in large, industrial-sized ovens. Multiple polymer layers are blasted with temperatures up to 750°F and solidified to form a solid, resilient material. However, with this approach, considerable energy is required first to heat the oven, then the gas around it, and finally the actual composite.

The MIT researchers tested the film on a common carbon-fiber material used in aircraft components, and found that the film created a composite as strong as that manufactured in conventional ovens — while using only 1% of the energy.

Heat generation

The group first developed a technique to create a film of aligned carbon nanotubes composed of tiny tubes of crystalline carbon. The researchers used a rod to roll the tubes flat, creating a dense film of aligned carbon nanotubes.

In initial experiments, the MIT research team integrated the film into airplane wings via conventional, oven-based curing methods, showing that when voltage was applied, the film generated heat. They then investigated the film’s potential to fuse two types of aerospace-grade composite typically used in aircraft wings and fuselages. Normally the material, composed of about 16 layers, is solidified, or cross-linked, in a high-temperature industrial oven.

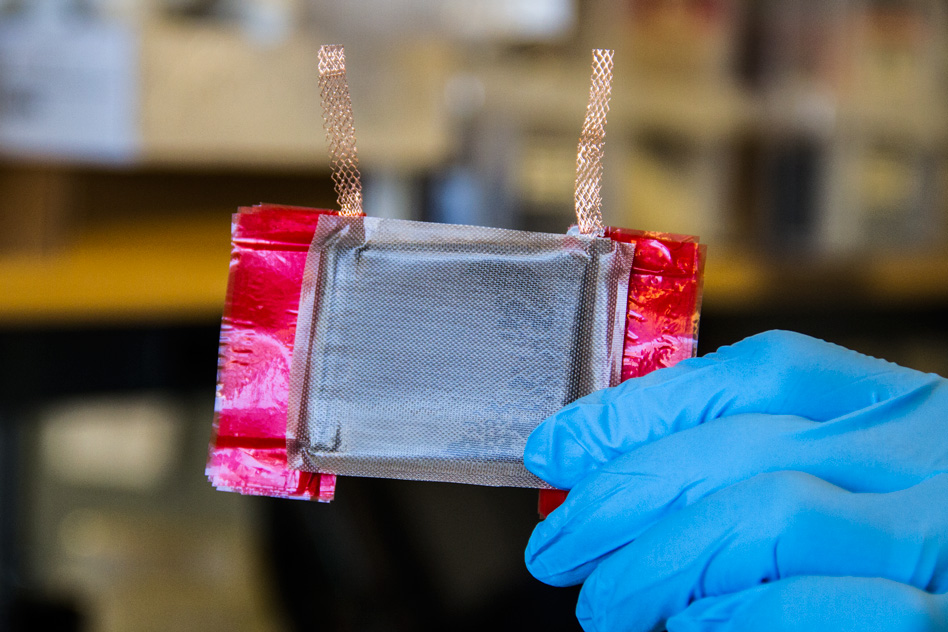

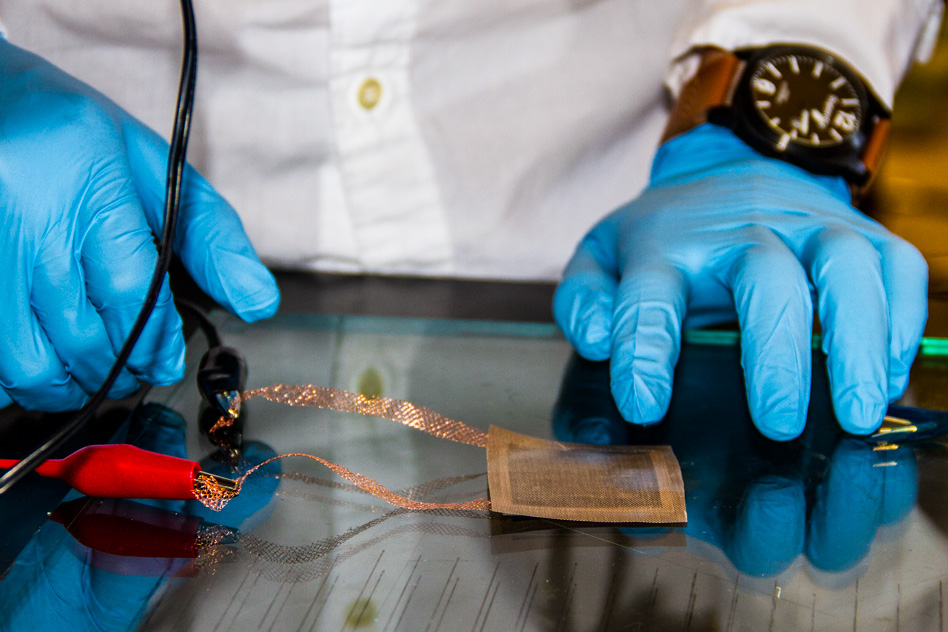

The researchers manufactured a CNT film and placed the film over a square of Cycom 5320-1. They connected electrodes to the film, then applied a current to heat both the film and the underlying polymer in the Cycom composite layers.

The MIT team measured the energy required to solidify, or cross-link, the polymer and carbon fiber layers, finding that the CNT film used one-hundredth the electricity required for traditional oven-based methods to cure the composite. Both methods generated composites with similar properties, such as cross-linking density.

Saving energy

The new ’out-of-oven’ approach may offer a more direct, energy-saving method for manufacturing virtually any industrial composite, according to Brian L. Wardle, an associate professor of aeronautics and astronautics at MIT.

‘Typically, if you’re going to cook a fuselage for an Airbus A350 or Boeing 787, you’ve got about a four-story oven that’s tens of millions of dollars in infrastructure that you don’t need,’ he said. ‘Our technique puts the heat where it is needed, in direct contact with the part being assembled.’

Wardle says the carbon nanotube film is also lightweight. After it has fused the underlying polymer layers, the film itself, which has a fraction of a human hair’s diameter, meshes with the composite, adding negligible weight.

The group also tested the film’s ability to generate higher and higher temperatures, and found it topped out at over 1000°F. In comparison, some of the highest-temperature aerospace polymers require temperatures up to 750°F in order to solidify, Wardle said.

The team is now working with industrial partners to find ways to scale up the technology to manufacture composites large enough to make airplane fuselages and wings.

‘There needs to be some thought given to electroding, and how you’re going to actually make the electrical contact efficiently over very large areas,’ Wardle says. ‘You’d need much less power than you are currently putting into your oven. I don’t think it’s a challenge, but it has to be done.’

Aerospace applications

Gregory Odegard, a professor of computational mechanics at Michigan Technological University, says the group's carbon nanotube film may go toward improving the quality and efficiency of fabrication processes for large composites, such as wings on commercial aircraft. The new technique may also open the door to smaller firms that lack access to large industrial ovens.

‘Smaller companies that want to fabricate composite parts may be able to do so without investing in large ovens or outsourcing,’ says Odegard, who was not involved in the research. ‘This could lead to more innovation in the composites sector, and perhaps improvements in the performance and usage of composite materials.’

This research was funded in part by Airbus Group, Boeing, Embraer, Lockheed Martin, Saab AB, TohoTenax, ANSYS Inc., the Air Force Research Laboratory at Wright-Patterson Air Force Base, and the U.S. Army Research Office.

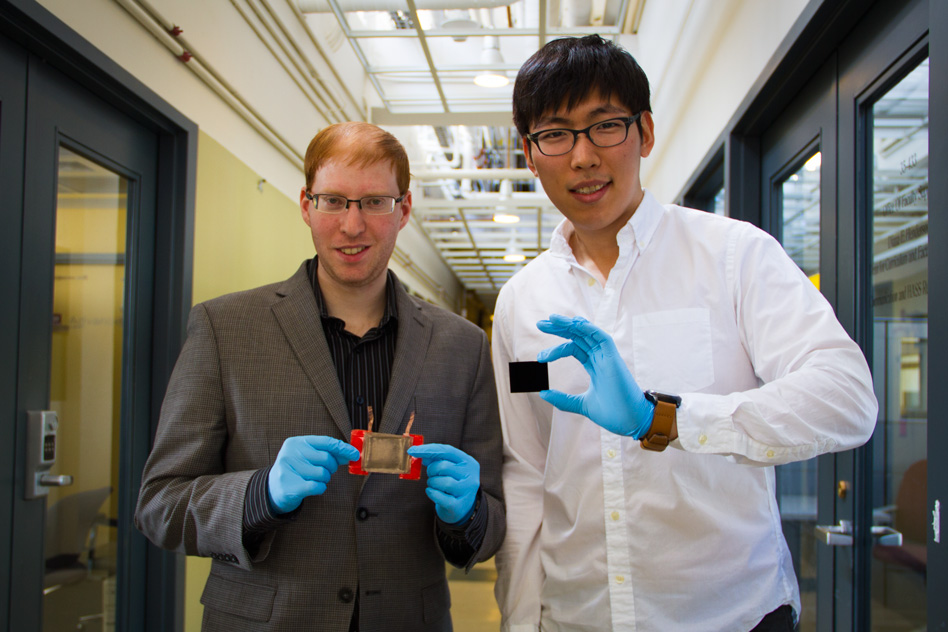

The team, including MIT graduate students Jeonyoon Lee and Itai Stein and Seth Kessler of the Metis Design Corporation, has published its results in the journal ACS Applied Materials and Interfaces.

This story is reprinted from material from MIT, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.