NAWA, which makes nano materials, says a US downhill mountain bike team is using its carbon fiber reinforcing technology to make stronger composite racing wheels.

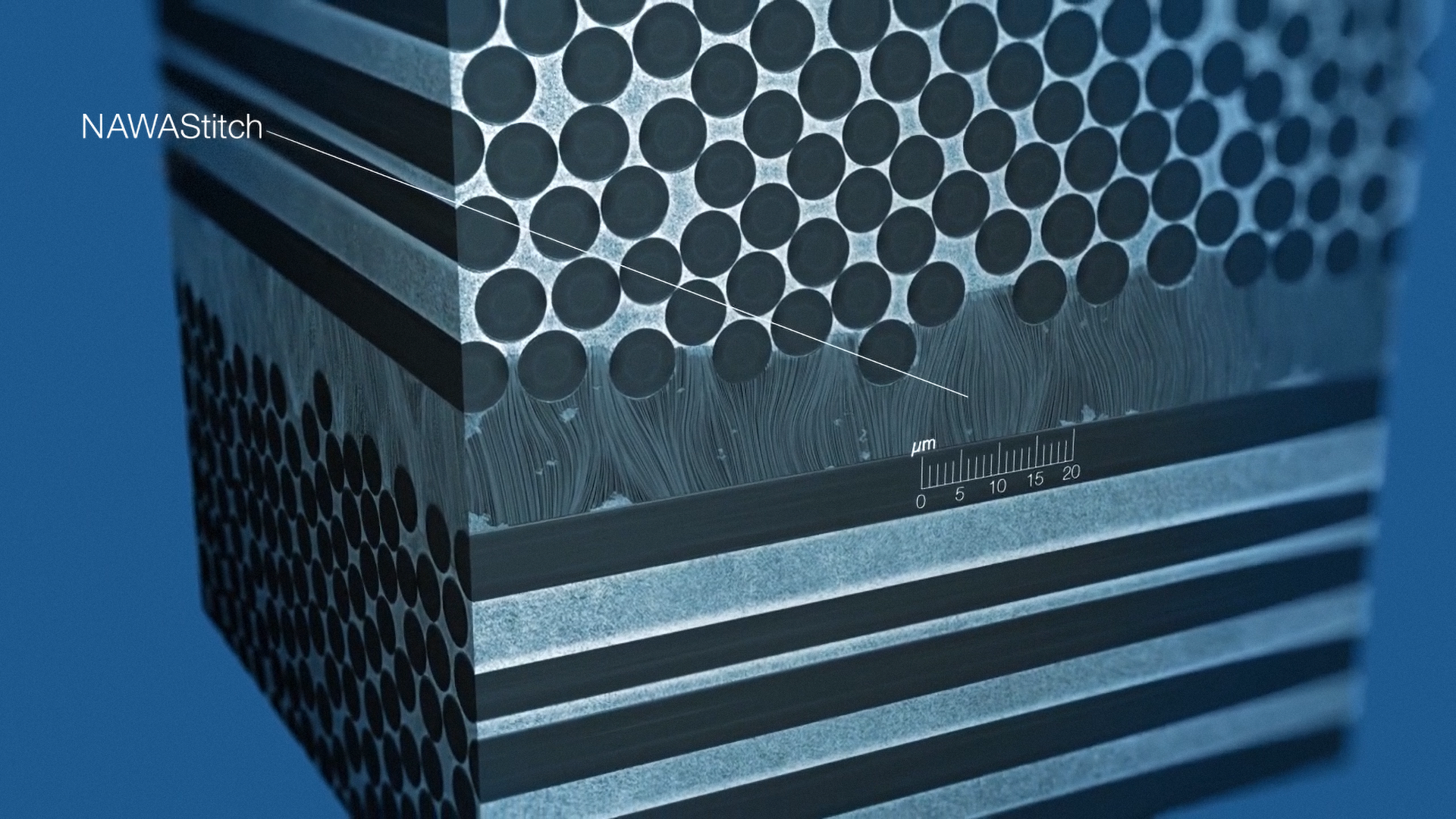

The wheels feature the company’s NAWAStitch technology, which incorporates a thin film containing trillion of vertically-aligned carbon nanotubes (VACNT) arranged perpendicular to the carbon fiber layers of the wheel. Acting as ‘nano-velcro’, the tubes reinforce the weakest part of a composite: the interface between the layers. The tubes are manufactured by NAWA using a patented process and, when applied to composites, can add superior strength to the structure and improved strike damage resistance. In in-house tests, NAWA says that NAWAStitch-reinforced carbon fiber composites have shear strength increased by a factor of 100 and shock resistance by a factor of 10.

Using NAWAStitch could therefore reduce the number of wheel failures experienced by the Santa Cruz Syndicate team over a competitive season by 80%, the company said.

‘In downhill racing, the wheels suffer hard, repeated impacts with rocks and roots,’ said senior composites engineer Nic McCrae, from Santa Cruz. ‘Failures occur when the tire bottoms out and the rim bead cracks. NAWAStitch has made the wheels much stronger, we believe by increasing the buckling resistance of the inner surface of the rims during these high compressions.’

NAWA America says that it is finalizing development of NAWAStitch for use in volume industrial applications and expects to ramp-up to full production by next year.

This story uses material from NAWA, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.