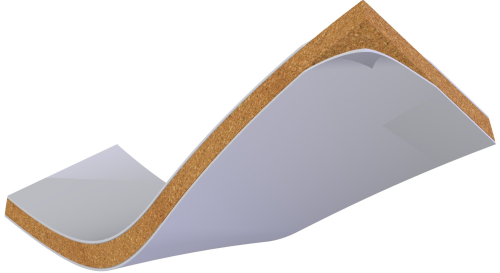

Cork material exhibits low water absorption and low resin uptake, which can lead to reduced resin consumption and weight savings. In addition, cork provides vibration damping and sound attenuation properties in sandwich composite structures, the company relates. Corecork, which can withstand processing temperatures up to 150°C (302°F), is available in several densities, tailored to specific performance levels. The low density of the material, its flexibility and conformability enable the integration of Corecork into fast production cycles, notes Amorim. Comparative data measured on sandwich panels show that Corecork meets or exceeds the performance of similar fibre reinforced plastic (FRP) panels made with synthetic cores, the company adds. Amorim cork was used in an award-winning project completed by a Danish architectural firm. 3XN architects won a 2010 JEC Innovation Award in the Environment & Recycling category for a green structure made with sustainable and intelligent materials during a Copenhagen climate conference. The project incorporated sandwich composites produced using bio-based and reusable materials. Sheets of cork served as the core, while the outer facings were made from flax fibres in a soybean-based resin.

This article is an extract from the feature Sandwich structures deliver core benefits, published in the July/August 2010 issue of Reinforced Plastics magazine. Read the complete feature here.