The Massachusetts Department of Transportation (MassDOT) and the Massachusetts Department of Conservation Resources selected the composite bridge deck to be an integral component of North Bank Bridge. This new 690 ft structure links Cambridge and Charlestown, Massachusetts, and provides access to the Charles River parklands, just across the river from downtown Boston.

The Composite Advantage FRP deck features five different panel sizes to accommodate the project’s requirement for a curvilinear shape. The bridge’s fluid form allows it to span water, cross a railroad, skirt launch pads for tour boats and bypass a historic building.

“This project was a little bit different,” explains Scott Reeve, President of Dayton, Ohio, based Composite Advantage.

“Unlike most deck-on-beam construction applications, our FRP bridge deck was engineered as an integral component of the overall structural arrangement along with tubular steel trusses. The composite and steel truss combination positions the bridge deck to act as the shear connection. This approach made it possible for the designer to create an iconic landmark with visual impact while meeting structural requirements.”

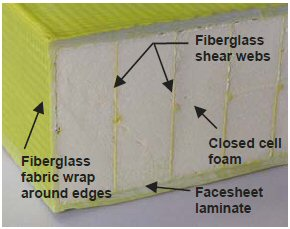

The deck was manufactured with Composite Advantage’s sandwich construction which employs composite top and bottom skins and closely-spaced internal webs that function like a series of I-beams.

Composite Advantage moulded the 10.3 ft by 12 ft panels with a 5 inch depth and an epoxy aggregate non-slip coating.

To enhance the bridge’s appearance in its natural setting, the FRP deck’s colour was coordinated with the steel.