The new pedestrian bridge was designed to connect two main facilities at the Wolf Trap Performing Arts Center and provide safe crossing over the 10-lane Dulles Access and Toll Road.

Steel trusses fitted with the 8000 ft2 composite bridge deck will be able to accommodate Wolf Trap patrons, cyclists and pedestrians as well as residents that will need access to the Metro stations currently under construction at Tysons Corner.

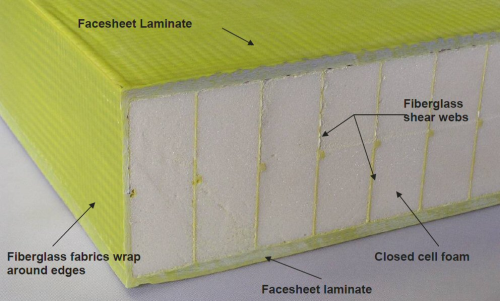

The FRP bridge deck was manufactured with Composite Advantage’s innovative sandwich construction which employs fibreglass top and bottom skins and closely-spaced internal webs that function like a series of I-beams (see picture right).

Composite Advantage moulded the 8.3 ft by 15.5 ft panels with curbs and an epoxy aggregate non-slip coating. The deck colour was coordinated with the truss coating.

Composite Advantage’s lightweight prefabricated panels accommodate the growing trend for night time construction which minimises the impact of construction operations on the public. The FRP decking was installed on each truss span adjacent to the bridge site. The light weight of the FRP deck enabled the fully assembled truss span to be lifted into place over the highway. The erection of each span required just 15 minutes of road closure. Each bridge span was lifted into place on three consecutive nights with the largest span measuring 170 ft2 and weighing 140 000 lbs.