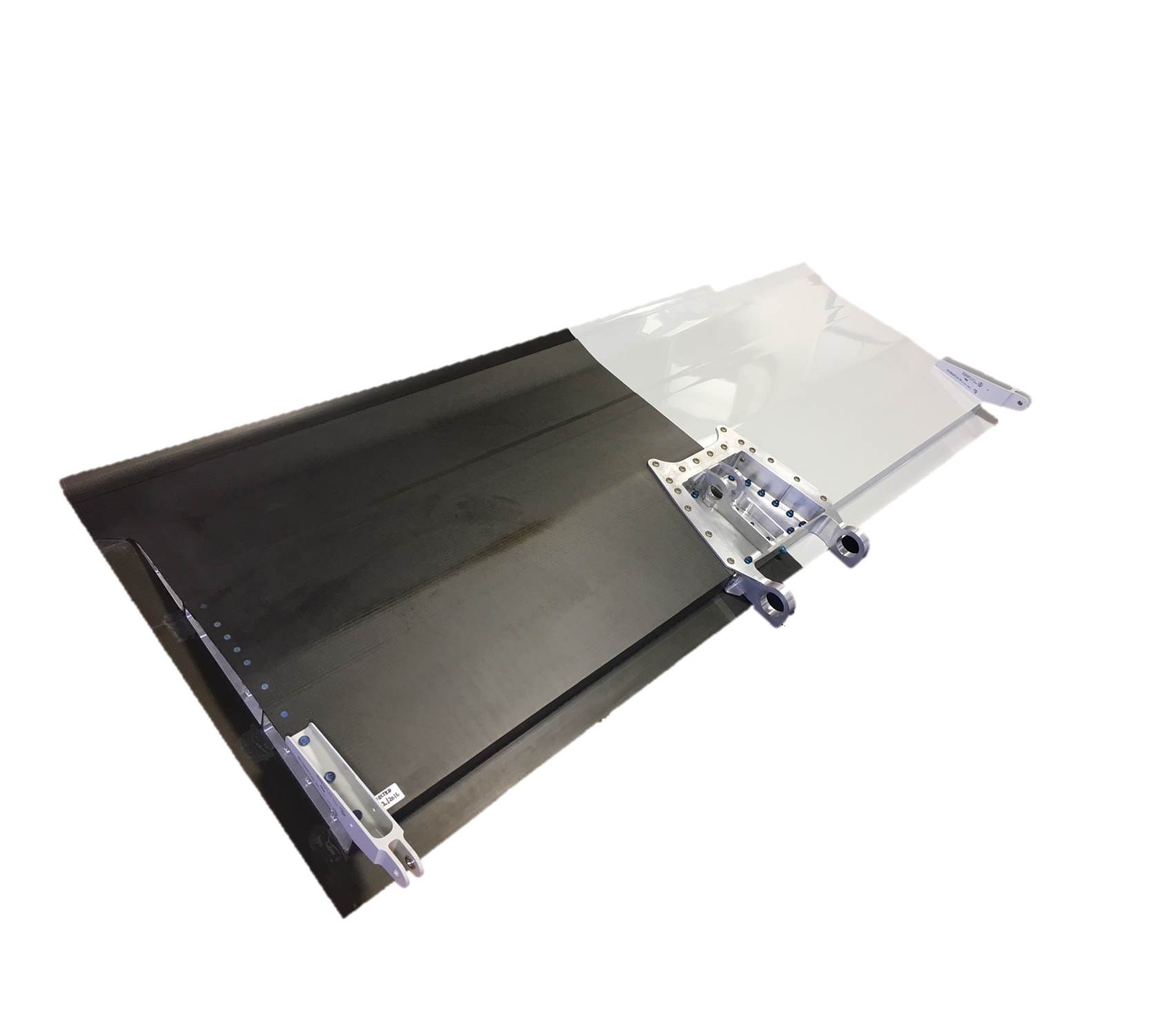

Teijin Limited says that its Tenax dry reinforcements (DR) carbon fiber material is now qualified to produce Airbus A320neo wing spoilers using resin transfer molding (RTM).

The automated RTM process can now incorporate Tenax dry reinforcements non-crimp fabrics (DRNF) and dry reinforcements braided fibers (DRBF) to form skins and stiffeners while maintaining existing product interfaces, so that final spoiler components can be directly replaced, the company said.

Teijin says that its Tenax DRNF materials are made of bundled carbon fiber filaments spread out in one direction in multiple layers with different directions, depending on the final component`s structural requirements, while Tenax DRBF can be applied within the spoiler component structure to act as cavity fillers. Both materials have been qualified individually by Airbus specifically for this application.

The combination of the Tenax DRNF and Tenax DRBF achieve the Spirit AeroSystems criteria for aircraft component production such as effective process ability, productivity, and cost efficiency. A320neo spoiler components will be manufactured within a new high-volume production facility in Spirit AeroSystems, Prestwick, Scotland.

This story uses material from Teijin, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.