According to Luca Amato, Team Leader Composites & XCell, DSM Composite Resins, the new resin system, designated ZW7844, is based on a proprietary chemistry and exhibits static and dynamic mechanical performances comparable to the current epoxy benchmark systems.

At the same time it provides a significant reduction of cycle time as the result of processing and curing behaviour similar to unsaturated polyester resins.

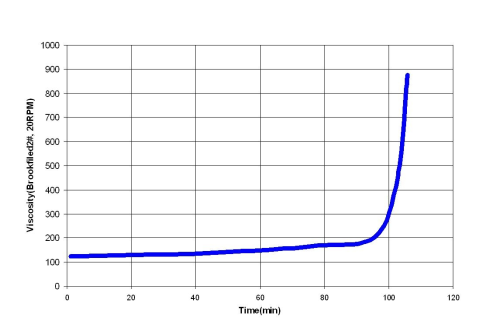

ZW7844 has a very low viscosity of 150 mPas at 23°C and it cures at room temperature. This means that wind turbine blade producers do not need to invest in expensive heated moulds when they choose this resin technology.

The resin is also said to offer:

- a pot life of more than 90 minutes;

- manufacture of thick and thin laminates;

- compatibility with multiple glass fibre types; and

- excellent fatigue performance.

The resin is currently being trialled in preparation for qualification. If successful, the first test blades could be produced in 12 months time.

This story is based on the feature New blade resin offers increased productivity, which was published in the July/August 2012 issue of Reinforced Plastics magazine.

You can also read the complete feature here.