3D Printing Engineering has developed new design, 3D colour modeling, tooling and rapid manufacturing services using 3D Systems 3D printing technology, which it will be showcasing at the TCT Show.

This comprises a customised end-to-end service, from an initial CAD modelling and design engineering, through to manufacturing 3D printed direct tooling, prototypes and small pre-production batches of 3D printed finished parts.

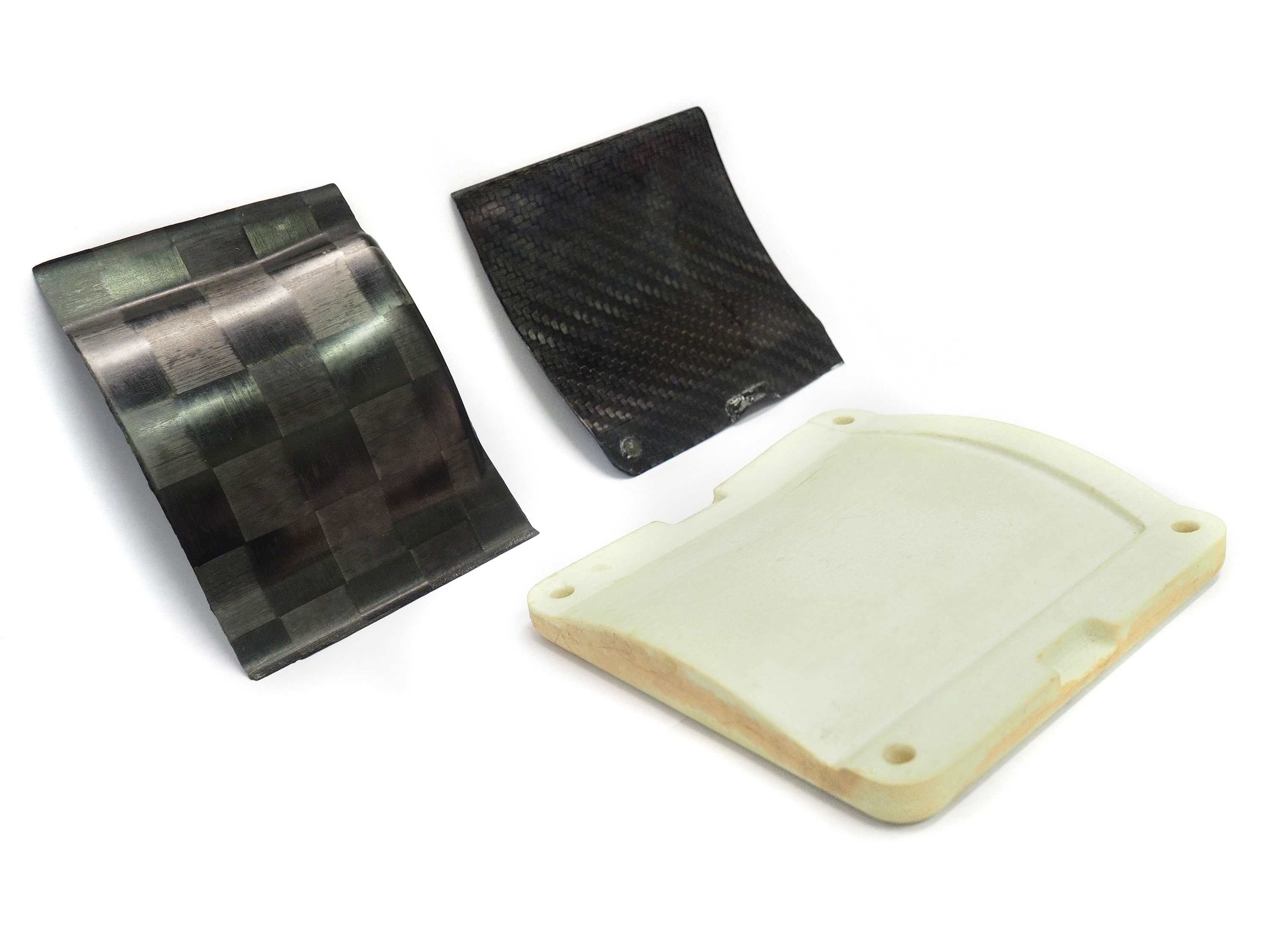

During TCT, which takes place in Birmingham, UK at the end of September, the company will be showcasing its latest developments in rapid build 3D printed direct tooling blocks, for low and high temperature/pressure autoclave moulding (to 135°C, 90 psi) glass and carbon fiber reinforced composite parts, or for ambient temperature moulding or casting rubbers and engineering thermoplastics. The full RBR tooling range (100/120/140/160)includes advanced production tooling with the same cure cycles as are typically used for aluminum and carbon tools.

This story is reprinted from material from 3D Printing Engineering with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.