(Companies listed in alphabetical order.)

Delpro will be offering details of its new unidirectional (UD) and prepreg composite production line, together with information on its range of standard and/or customised prepreg machines and other composite material processing equipment, all of which is available for inclusion in original machinery installations or for retrofit to existing plant.

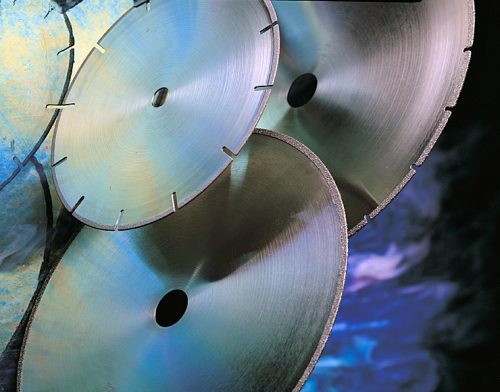

Super-abrasives manufacturer Engis offers a range of products for the slicing and grinding of composite materials, including electroplated diamond saw blades and small diamond wheels, particularly for automotive and aerospace applications. In the case of larger blades Engis also offers a strip and re-plate service.

EPSRC Centre for Innovative Manufacturing in Composites

The EPSRC Centre for Innovative Manufacturing in Composites will showcase technologies developed within its current research activities such as through thickness stitching, automation for prepreg and dry fibre preforming, and multi-scale infusion simulation.

Led by Professor Andrew Long at the University of Nottingham, the EPSRC Centre delivers a co-ordinated programme of research at four leading UK universities in composites manufacturing – Nottingham, Bristol, Cranfield and Manchester. It is the focus for fundamental innovative composites manufacturing research in the UK, underpinning the development of next-generation composites manufacturing processes based on low cost, short cycle times, efficiency and sustainability.

The EPSRC Centre currently employs 10 academics and 19 researchers across the four core member sites. A new activity is the Industrial Doctorate Centre (IDC) which has attracted new funding of £3.8 million from the UK Engineering and Physical Sciences Research Council, supporting over 30 EngD programmes for research engineers based in industry, of four years duration.

Following the Composites Engineering show, the Centre will launch a call through the EPSRC to fund up to eight six-month feasibility studies in highlighted areas of composites manufacturing research. A number of these will be awarded to universities outside of the core partnership.

FORMAX, a manufacturer of carbon fibre and speciality reinforcements, will be showcasing a range of products for the automotive, marine, wind energy, sports and industrial markets. Following significant growth globally, the company is now keen to strengthen relationships with UK composite part manufacturers seeking a competitive edge with a cost effective solution.

Product highlights include:

- lightweight carbon fabrics for industrial applications;

- specialised glass fabrics for marine and Industrial applications; and

- heavyweight glass fabrics for Infusion processes.

SCIGRIP will be showing its structural adhesives, which are used by customers in the marine, transportation, construction and product assembly markets.

Product sighlights include:

- SG230HV Series: an established adhesive in the US marine sector. This high build and low exotherm product produces tough results after cold cure and is suitable for marine, bus, truck, rail, wind and other renewable energy applications;

- SG300 Series: a primerless metal bonder. This low read through, high fatigue and high shear strength product produces excellent results on composites, metals and plastics bonded to themselves and each other. It replaces or reduces the need for metal fasteners;

- SG100 Series: this bright white, permanently toughened adhesive is designed for marine use. It avoids traditional yellowing of other ‘white’ supplies, requires minimal surface preparation and demonstrates excellent non-sag properties.

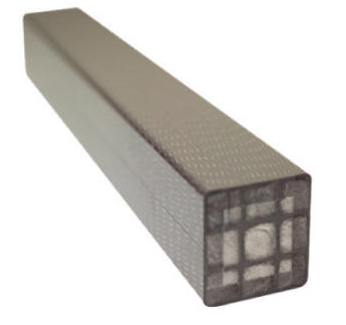

Scott Bader Ltd will focus on its range of primer-less Crestabond® methacrylate structural adhesives which require no, or only minimal, surface cleaning of bond surfaces. During the show, Dr Gavin Creech from Scott Bader’s R&D Applications Engineering Group will give an open forum presentation titled: Engineering with Structural Adhesives – practical advice on the use of structural adhesives with composites, metals and plastics. The company will also feature the award-winning Axontex™ carbon composite structural beam technology, which uses Scott Bader's Crestapol® 1250LV high performance resin. The moulded Axontex carbon composite beam has a unique internal structure with shear webs which, combined with the mechanical properties of the Crestapol resin, provides the very high stiffness and strength of this lightweight composite structural system. Axon Automotive Ltd's system is ideal for producing a very lightweight transport vehicle frame needing both rigidity and high impact crash resistance performance. Other products in the Crestapol range of high performance resins will also be exhibited. Crestapol resins have been specially developed for manufacturing, by closed mould or pultrusion, high performance glass and carbon fibre reinforced, filled composite parts with exceptional fire, smoke and toxicity resistant (FST) properties. They are suitable for buildings, passenger rail and other land transportation applications.

Scott & Fyfe Ltd is launching its new line of carbon fabrics for the composite industry under the Polycarb brand. Starting with unidirectional carbon tapes in weights of 100-1000 g/m2, the product family will be extended to include a range of specialised high performance fabrics that are focused on the specific needs of the company's customers and target markets.

♦