| Composite patching needs to become higher-tech in order to speed up the repair process in the field. |

‘Patching it up’ is a phrase suggesting makeshift and temporary repair, but this connotation is misplaced when it comes to the latest commercial and military aircraft. Even metal patches, widely accepted for quickly repairing modest damage to metal or composite aerostructures, have to be carefully produced and applied in line with instructions given in the structural repair manual (SRM) that is issued for each aircraft type. Now airframe repairs are reaching a new level with composite patches becoming an increasingly attractive option to metal.

Reinforced plastic patches have significant advantages. They do not corrode and, where bonded, they avoid the stress concentrations present around rivets or other mechanical fasteners that can lead to cracking. They can be applied to structures of metal or composite – whether sandwich or monolithic. Aircraft MRO (maintenance, repair and overhaul) practitioners are learning that even the pressurised fuselages of the latest 50% composite airliners, such as the now in-service Boeing 787 Dreamliner, can be repaired successfully with them.

But composite patching needs to become higher-tech in order to speed up the repair process in the field. Airlines and other operators hate repairs that keep aircraft on the ground and do all they can to minimise downtime. Clearly, manual wet lay-up, though acceptable for secondary structures such as fairings, is a non-starter at this level and pre-cured composite patches have gained currency instead. Yet even this technology is being held back by the bogey of cure time. Until fast cure, rapid repair techniques emerge, composite patch repairs may still lag behind metal. The advent of aircraft that are extensively composite, like the Boeing 787 and Airbus A350 passenger jets and the vertically landing F-35 Lightning II fighter, makes the matter even more pressing.

Nanotechnology approach

Composite patching technology has been the focus of much research globally. In Europe, corporate/academic collaborations have led the charge, thanks in large measure to European Union financial encouragement. Over the last decade, a number of consortia have addressed aspects as varied as patch repair of composite and metallic aerostructures, portable laser preparation of composite repair surfaces, resistive and induction heating of repair patches, cure optimisation, high temperature curing of large composite repairs and non-destructive evaluation (NDE).

One of the most interesting of these initiatives was the three-year programme IAPETUS which, though it ended two years ago, continues to attract attention. Nanotechnology is key to the approach pioneered by the international consortium of five commercial and three academic organisations led by Tecnalia of Spain. Huntsman Advanced Materials GmbH supplied the mainly carbon fibre/epoxy composite materials, while Daher Aerospace and Hellenic Aerospace Industries focused on repair production and application.

By incorporating carbon nanotubes (CNTs) into the composite patch and adhesive, the materials can be made electrically and thermally conductive, whereas without the CNTs they are poor conductors. Applying a voltage across the partially resistive CNT-enriched composite patch enables the composite to be heated. Because the heat is generated inside the lay-up rather than by some external means such as a heat blanket, it is closer to the curing resin, resulting in a more rapid cure. And, thanks to the composite’s thermal conductivity, the heat is more evenly distributed, promoting uniform matrix polymerisation.

A further consequential benefit is the potential to continuously monitor repair integrity. Cracking can be detected because as soon as microcracks start to form in the composite the CNT network becomes disrupted; hence by monitoring changes in conductivity within each ‘smart’ patch, potentially damaging stresses can be revealed.

IAPETUS researchers established through tests on coupons and sample repairs that CNT inclusion can enhance both mechanical and bonding performance, resulting in repair quality surpassing that achievable with other out-of-autoclave techniques. Peel and shear strengths, for example, are said to be improved. The chief benefit, though, remains the faster cure achieved by internal heating.

AeroPlan

The high promise of this nanotechnology-based approach has been recognised within a final ‘sweep up’ programme, AeroPlan, with which the EU aimed to organise the disparate findings from the eight previous research programmes it had funded, and to tempt industry to accept and apply them. The five-state, seven-organisation AeroPlan consortium finished its official programme in February this year, having presented its consolidated body of knowledge at a number of conferences and other events.

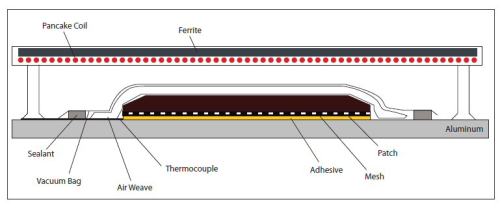

An important area of focus was ways of heating the applied composite patch to bring about the final cure. Resistive heating, as described, is one way. Another is inductive heating and this was the method explored in the INDUCER study, one of the earlier research elements that fed into AeroPlan. This system relies on a patch structure in which metallic content – a mesh or dispersed conductive fibres –- is included in the lay-up. After the patch has been applied to the pre-prepared repair site and vacuum bagged, the metal within the patch is heated inductively by passing a current through an induction coil placed over it.

Like the resistive method, inductive curing also comes with the possibility of continuous health monitoring. It was shown that magnetostrictive sensing arrays included in the laminate can be used to monitor the strains present in the composite element, and hence its health.

INDUCER participant GMI Aero of Greece, working with the National Technical University of Athens, developed the induction-based solution and produced prototype equipment for applying it. They demonstrated their technology at laboratory scale and indicated potential applications in bonding carbon composite patches to aerostructures of carbon composite, metals and thermoplastics. GMI Aero pointed out that generating heat inside the patch rather than from the outside with a thermal blanket has the further benefit of limiting the area to be heated, together with associated thermal losses, residual stresses and power consumption.

The company also addressed issues of thermal transfer and temperature homogeneity across the repair and its findings are influencing the design of more efficient thermal blankets and zonal heating. Attention paid to heat sinks, caused by underlying pieces of structure, and how they produce disruptive thermal troughs and peaks, also fed into the practical results.

|

Current economic world conditions in many countries both within and outside the EU are forcing the operation of both passenger and cargo aircraft well beyond their original design life, as the cost for replacing older aircraft becomes disproportional to the capability for long-term investment of many airlines. Most aircraft have been manufactured using aluminium alloys, which constitute the greatest percentage of their structure, while the use of composite materials, although increasing, is relatively limited. Even though repair techniques have been established by the manufacturers for the initial design life of the aircraft, it is well understood that there is an increasing need for innovative repair solutions, both for metallic and for composite structures, to restore structural integrity or to reinforce areas prone to damage, which would reduce operating costs by providing easy and low cost repair procedures, extending significantly their economic life while guaranteeing airworthiness and the corresponding flight safety. During the last ten years, the EC has funded research projects providing composite-based aircraft repair solutions, through the development of innovative elements that could assist in performing safer and more efficient repairs, in a faster and more economical way. As these innovations have been developed as the main or the secondary target of a large number of upstream research projects, their combination and adaptation to the actual aeronautical composite repair requirements is needed, together with their organised and systematic promotion towards the key players of the aeronautical industry, in order to maximise the impact of results facilitated by EC investment (funding). |

Both heating methods outlined, resistive and inductive, utilise patches modified to permit internal heating and it is this which makes shorter cure times possible. With conventional methods that apply heat to the outer layers of ‘standard‘ composite patches, these layers become hot well before the innermost layers can do so due to the low rate at which thermal energy is conducted from the outside in. This can result in the earlier hardening of the outer layer and consequent entrapment of volatiles still being emitted by the inner layers.

The induction principle also underpins the use of moulds or press tools that have embodied mesh or conductive fibres which can be heated when adjacent induction coils are activated.

Laser surface preparation

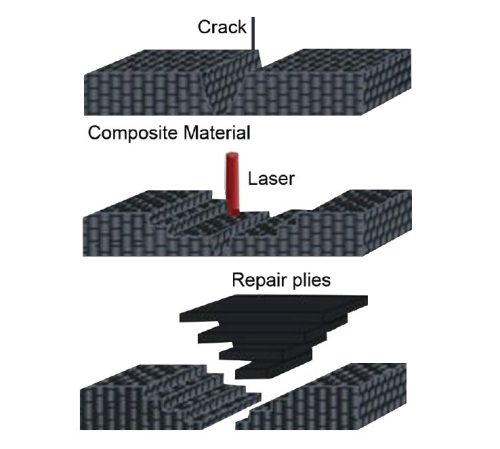

Vital for a strong bond between patch and the repair site is effective preparation of the substrate area. Surface preparation using a portable laser was the subject of the PLASER R&D programme summarised as part of AeroPlan. Researchers showed how this form of contactless pre-treatment can enhance the bond itself by effective site cleaning, whilst also greatly speeding up the preparation process by avoiding the lengthy highly-skilled manual abrading that is normally required.

Grinding and milling operations on hard carbon composite can wear out expensive tools quickly, may contaminate fibres with abrasive dust and, unless automated, are subject to human error. The laser process avoids these pitfalls and project partners Laser Zentrum of Hanover and GMI Aero Ltd adapted a portable system for attachment to aircraft structure. They concluded that their system could readily be automated and that it could then reduce time to repair by up to 80% and cost by up to 60%. For deeper, more complex repairs, the system proved able to remove composite material in a highly controlled way, one ply at a time, so that a chamfered edge could be produced. CleanLASER of Germany was no doubt fully cognisant of these findings when it developed its own laser pre-treatment to enable carbon composites to be bonded without chemicals or abrasives and with no waste.

GKN Aerospace (UK) and SCLR Lasertechnik GmbH (Germany) have gone further, developing a robotic repair cell in which a laser is used to remove damage ply by ply as part of an automated repair process. The partners claim that the cell, subsequently housed at GKN Aerospace’s Isle of Wight facility, can consistently deliver repairs that match the strength of present manually performed repairs, much faster and at reduced cost. Such automation, they argue, will inevitably be key to the future aftercare of composite aircraft, enabling these expensive assets to be kept in the air earning revenue rather than on the ground undergoing prolonged maintenance. ♦

Part 2 of this article looks at the composite repair techniques Boeing and Airbus are using.

This article was published in the September/October 2014 issue of Reinforced Plastics magazine.

The digital edition of Reinforced Plastics is distributed free of charge to readers who meet our qualifying criteria. You can apply to receive your free copy by completing this short registration form.