Part 1 of this feature looked at why practical experience is important for composites repair technicians. In Part 2 we review aircraft-specific training and review some training providers.

Aircraft specific

Recently Abaris has been training British Airways (BA) and Airbus engineers in a joint venture with hot bonder supplier Heatcon, at a facility in Bicester, near Oxford, UK (see Abaris completes composites training for British Airways and Airbus UK). However, from the end of this year, the Heatcon-Abaris Training partnership will be changed and Abaris will start operating courses independently at a new training facility in Amsterdam, the Netherlands.

Meanwhile within the present partnership, four separate Phase 1 and Phase 2 classes in Advanced Composite Fabrication and Damage Repair, have recently been provided for a dozen students in each case from British Airways Maintenance in Cardiff, South Wales. This subsidiary performs heavy maintenance on the airline’s long-haul aircraft.

Senior instructor Corrie Volinkaty, who headed up those courses, told Reinforced Plastics that laboratory work is tailored for specific airframes of interest to course participants. This is easier to arrange when, as in the BA case, a single airline has booked all the available course places, but efforts are made to provide relevance for all trainees even where a mix of client organisations is involved.

| Repairs may require anything from a prefabricated composite patch, suitable for most light ‘dings’, to a titanium doubler for cases of more severe damage. |

With composites now being specified for the aircraft fuselage as well as wings, empennage and control surfaces, some BA technicians will find themselves carrying out repairs to B787 fuselages when they suffer the seemingly inevitable knocks from ground service vehicles. Such instances have already occurred with other airlines. For example, a Japanese operated Dreamliner struck by a truck required a bonded patch repair to its fuselage. Additionally, several instances of lightning strike have resulted in damage ranging from the cosmetic to several plies of affected laminate.

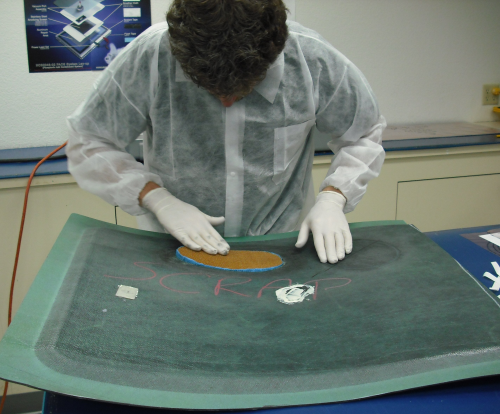

Repairs may require anything from a prefabricated composite patch, suitable for most light ‘dings’, to a titanium doubler for cases of more severe damage. Repairs may require anything from a prefabricated composite patch, suitable for most light ‘dings’, to a titanium doubler for cases of more severe damage. (Titanium because it does not corrode in the presence of carbon fibre reinforced plastic). Abaris acknowledges this and aims for basic competency in repairing fuselages as well as the more familiar composite aerostructures. It is also working on the development of more advanced airframe repair courses that will go beyond SRM limits, though success in this endeavour will depend on the degree to which airframe manufacturers are prepared to make proprietary structural information available.

Another customised programme the partnership ran recently was at the Airbus wing-making establishment at Broughton, UK. Training was largely focused on the new 50% composite A350 widebody twin-jet and included exercises and lectures in composite repair techniques, light manufacturing rework and repairs to foreign object damage (FOD) – the latter being damage caused by impacts from debris and other random objects.

Corrie Volinkaty explains that the course was designed primarily for production workers, was overseen by Airbus quality assurance professionals and was a combination of Phases 1 and 2 content tailored particularly to Airbus requirements.

British Airways, like a number of major airlines, also undertakes composites training of its own, preparing line and base maintenance technicians to repair slight to moderate damage that would normally be within the scope of the Structural Repair Manual. In preparing for the current induction into its fleet of both the Boeing B787 and the Airbus A380 superjumbo, BA has invested in expanded facilities at its BA Engineering Learning Academy. Enhanced ability to provide Part 66 basic skills training for category A, B and C licences includes improved facilities for instruction in composites and structural repairs. The Academy was the world’s first approved training school able to deliver both B787 and A380 B1/B2 training. With an eye to the growing maintenance and repair aftermarket, it offers training for third parties as well as its own technicians.

More training suppliers

UK-based Dark Matter Composites offers a Composites Repair (Stage 1) course in which 70% of content is practical, based on demonstrations and hands-on exercises. Topics range from detection and evaluation of damage through temporary repairs to high quality permanent repairs. In dealing with a range of test specimens, students are assessed on such capabilities as step-sanded surface preparation, identification of laminate plies, application of orientated materials, vacuum bagging, curing, surface finishing, blending and polishing. Although the course is general in scope, it can form a good foundation for aircraft repair work.

Aerospace participants in Dark Matter courses have praised them for their hands-on nature and a good balance between theory and practice.

As one higher-level course participant commented: “The practical elements were most useful to myself as an experienced engineering graduate. The theory was similar to degree material but the practical was an opportunity rarely offered or encountered.”

FL Technics Training of Latvia provides a Composites Repair Theoretical and Practical Course designed to equip students to carry out repairs in accordance with SRM instructions. Participants receive a Part-147 certificate on successful course completion.

Another organisation that emphasises the importance of hands-on practice is Advanced Composites Training (ACT), the training division of Renaissance Aeronautics Associates Inc, (RAA) based in Ontario, Canada. ACT aims to provide technicians with the ‘right mix of theory, hands-on instruction and enabling technologies.’

RAA was the first privately-owned company in Canada to receive both Transport Canada approval and Canadian Aviation Maintenance accreditation to teach repair and manufacturing processes for advanced composite aircraft structures. Course status is emphasised by the fact that the Federal Aviation Authority (FAA) in neighbouring USA has accepted 12 of ACT’s composites courses as qualifying for Inspector Authorisation renewal.

Tailored courses are conducted at customer sites worldwide or at ACT facilities. Sometimes customer facilities are best since they can combine well equipped workshops and clean areas with fleet proximity so that courses can embody real-environment learning opportunities. Trainees avoid extra travel expenses and are likely to feel more comfortable in their own familiar surroundings. It can be a cost-effective option, says the company, for six or seven employees at a time, provided classroom facilities are available.

After taking two initial course modules in materials and structures then damage and repairs, students can progress to a third module that deals with advanced structural repairs that are beyond the scope of the SRM. Clients have included the likes of Air Canada, US Air, Bombardier Aerospace and Eurocopter.

ACT favours the use of WichiTech Composite Repair Systems, mainly hot bonders with associated test and ancillary equipment.

Recently ACT has extended its reach across the Atlantic to Ireland, by regularly providing courses at the FAS Training Centre in Shannon, in conjunction with Ireland-based All-Round Composites Ltd. (FAS is the country’s Training and Employment Agency.)

GA too

Not all development in the MRO sector is driven by commercial passenger aircraft. Light and sport aircraft (known as general aviation or GA types) are, similarly, becoming extensively composite.

Cessna Aircraft, as one example, has certified ACT as an approved trainer for structural repair techniques on its all-composite Corvalis 350/400/TTX (formerly Columbia) light aircraft family. After suffering some material quality-related issues in its Corvalis programme, Cessna wanted to enhance the capabilities of the repair technicians that work in its global service centre network and enlisted ACT to help.

Certain small aircraft firms provide their own in-house training. For instance, Cirrus Aircraft operates a 40-hour composites repair course that is aimed primarily at technicians in authorised service centres that will have to repair its aircraft. Content majors on repairs that can readily be carried out in the field without expensive equipment or the need for high temperature, high pressure cures. Repairs taught are in line with the company’s Aircraft Maintenance Manual and typically involve cutting out a damaged area and then, after appropriately preparing the damage site, bonding in a replacement section that has been pre-fabricated in the factory.

Meanwhile, in terms of the largest repair to a commercial airliner composite structure ever attempted, Boeing is still (at time of writing) in discussions with its customer, Ethiopian Airlines, and insurers about how to reinstate the airline’s B787 that caught fire at Heathrow. Action will certainly involve more than cutting away the damaged area of carbon composite skin and replacing it with a patch. Stringers and other structure beneath the skin will likely require evaluation, renewal and testing. Special NDT will be needed to establish whether, in the periphery of the affected area beyond where damage is obvious by virtue of charred fibres, laminate properties have been degraded by excessive heating of the resin. (A hand-held infra-red spectrometer developed over the last three to four years is said to work well in identifying such thermal degradation.)

Expertise garnered by the airframer over several years in repairing large B777 twinjets, though useful, will not alone suffice. Major structural repairs to fuselages, the crucial pressurised passenger-carrying element of the aircraft structure, are new territory and as Boeing treads carefully into it, airlines and aircraft producers around the world will be watching with interest. So will the composites education community as it adapts to the new material environment. ♦

See also:

Meeting the challenge of composite fuselage repair

This article was published in the November/December 2013 issue of Reinforced Plastics magazine.

The digital edition of Reinforced Plastics is distributed free of charge to readers who meet our qualifying criteria. You can apply to receive your free copy by completing the registration form.