Companies are listed in alphabetical order.

3B Stand number M25 Website: www.3b-fibreglass.com

In partnership with Arkema, a leading producer of PMMA (polymethyl methacrylate), 3B has developed a sizing technology designed to reinforce acrylic thermoplastic systems for structural applications. 3B and Arkema, partnering with weaver Chomarat, are launching products which are alternatives to existing thermoset systems.

3B’s benchmark series of high performance rovings, which include SE2020, HiPer-tex™ W2020 (both recently Germanisher Lloyd approved) and W3030, will also be exhibited. Designed for various resin systems such as epoxy and polyester/vinyl resin for resin infusion moulding and prepeg processes, they are principally (but not exclusively) used in wind turbine applications. Luc Peters, 3B Wind Energy Technical Leader, will deliver a presentation highlighting these new glass fibre reinforcements on 13 March.

Thanks to 3B’s HiPer-tex high performance rovings, Madshus, a Norwegian creator of winter sports equipment, has designed lighter, stronger and faster skis which will be displayed on 3B’s stand and at the Innovation Showcase.

Ahlstrom Stand number W64 Website: www.ahlstrom.com

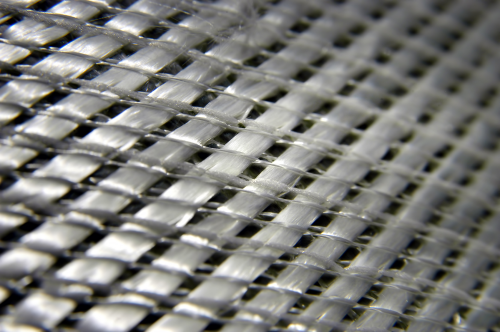

Ahlstrom, a supplier of reinforcements serving composite customers in the marine, wind energy, transportation and building industries, has developed a new range of multiaxial reinforcements for infusion and closed mould systems. The products are said to enable excellent resin flow as well as high strength. Characteristics of the new multiaxial reinforcements include:

- a unique channel structure which remains permeable, allowing resin flow even under high vacuum compression;

- increased mould filling speed;

- ensures complete impregnation of critical areas;

- one layer of this channel structure reinforcement helps wet out several layers of standard reinforcement.

For transportation, marine and building applications Ahlstrom will showcase RTC - Reinforced Thermoplastic Composite. This is said to be ideal for producing small to medium volume series in the press forming process. Benefits of RTC include: simple and economical tools (e.g. wooden moulds); fast moulding process; low labour cost; lightweight parts; and possibility to manufacture textile, felt, TPO clad parts in one shot.

Airtech Stand number M64 Website: www.airtech.lu

Airtech will be highlighting products designed to make the resin infusion process easier, including the resin infusion adapter (RIA), a practical tool which can ensure the connection between the resin inlet tube or vacuum line and all resin infusion connectors, and SIL-TUBE, a flexible heat and chemical resistant tube suitable for room to high temperature resin infusion applications where it can be used as a vacuum channel or as a resin inlet tube.

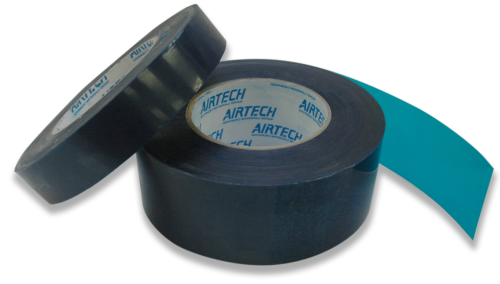

The company will also showcase the latest products the Airseal sealant tape range:

- Airseal 2 ST, a cost effective sealant tape with strong tackiness which provides an immediate and excellent adhesion to most surfaces for vacuum bag applications up to 150°C; and

- Airseal 2 HT Twin, designed for vacuum bagging applications requiring double bagging. The simultaneous application of the two stripes of sealant tapes saves time, effort and increases the reliability of the process.

Airtech will also highlight products in its pressure sensitive tape range:

- Flashbreaker® PS1, a high temperature/high tensile strength polyester film coated with a high tack pressure sensitive silicone adhesive for oven or autoclave cures up to 204°C;

- Teflease MG2 Orange, a high tensile strength PTFE pressure sensitive tape with high temperature silicone adhesive providing increased wear properties when compared to standard PTFE tapes. It provides high visibility on most substrates;

- Flashbreaker 2CBS, a high temperature/high tensile polyester film coated on both sides with pressure sensitive silicone adhesive suitable for autoclave and oven applications up to 204°C. This product has been developed for securing secondary tooling, peel plies, release film, breather fabric and vacuum bagging films during high temperature and general workshop applications.

AkzoNobel Stand number F17 Website: www.akzonobel.com

AkzoNobel is extending its portfolio of cobalt-free curing solutions with the launch of its second generation Nouryact™ accelerators. These new accelerators are based on BluCure technology and are 100% cobalt-free. Primarily based on iron, the new Nouryact accelerators work in all temperature ranges and have a lower colour impact on the end products. They are said to be an easy to use replacement for existing cobalt-based accelerators and in some cases even outperform cobalt, enabling curing behaviour which cannot be achieved with conventional systems.

There are six different Nouryact accelerators which can be combined with the full range of AkzoNobel’s peroxide curing agents, offering a cobalt-free curing system for virtually every application. For resin producers and formulators, AkzoNobel offers innovative raw materials, such as Borchi® OXY Cure, and access to the BluCure Technology, to enable them to formulate cobalt-free resins for the composite industry.

AkzoNobel will release more information on these new developments will during a presentation on 13 March.

Alan Harper Composites Stand number N44 Website: www.alanharpercomposites.com

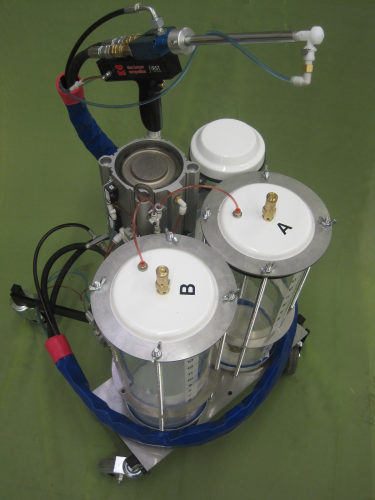

Alan Harper Composites, a producer of machines to manufacture reusable vacuum bags, will introduce its SilCon VI model. This provides all the advantages of the SilCon V model, with two robust 200cc fluid ratio pumps and a third 20cc pump which can add thixotropic additive on demand, but features two machine-mounted 15 litre clear tanks that can be pressurised to aid the use of thicker silicone fluids. This feature allows the machine to dispense and spray condensation cure silicones in addition to the addition cure types.

The company says that the new model covers a vast range of application in one machine: either two-component Platinum cure silicone, two-component silicone with thixotropic addition on demand or condensation cure silicone with tin cure catalyst pumping. The lightweight hand-held, highly manoeuvrable, spray gun head has been engineered to include the third fluid stream using the same compact disposable mixers.

Demonstrations of silicone bag manufacture will be conducted on the stand.

Anaglyph Ltd Stand number B14 Website: www.anaglyph.co.uk

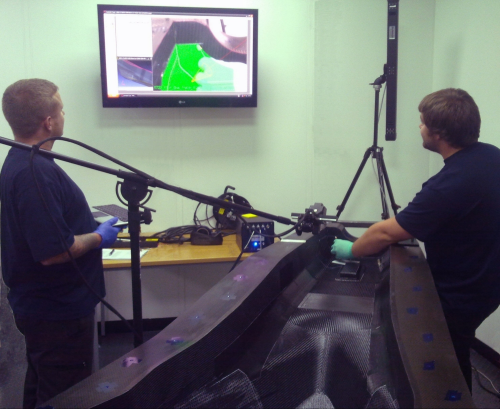

Anaglyph is showing its composite design and analysis software LAP, CoDA and Laminate Tools, as well as hardware/software for ply positioning control, PlyMatch.

LAP (Laminate Analysis Program) is used to analyse any type of composite laminate subjected to in-plane loads and moments. Typically, the software is used in preliminary design for tailoring a stacking sequence, then analysing the composite component with other methods such as finite elements, and finally optimising the design by inspecting the laminate behaviour layer by layer.

CoDA is used for preliminary analysis of sub-components with Plate, Beam, Joint, Flange or Laminate geometries. It can also synthesise the properties of composite materials, laminates and sandwich structures, which can be used in a seamless manner within the design modules.

Laminate Tools addresses the entire Geometry (CAD surface import), Design (draping simulation), FEA (pre- and post-processing) and Manufacture (ply-book preparation) sequence of design work. It interfaces with most industry standards, both CAD and FEA. Anaglyph will be introducing the new version v4.3 of Laminate Tools at the show.

Based on customer needs for accuracy in composites manufacturing, Anaglyph developed PlyMatch, a technology for hand lay-up visual control. Easy to use, compact and mobile, PlyMatch is an alternative, or a complement, to existing ply-placement methods. It is best used for small to medium sized plies with complex, highly curved shapes.

Anguil Stand number E43g (US Pavilion) Website: www.anguil.com

Air pollution control provider Anguil will provide information on the various emission control strategies for carbon fibre processing and composites manufacturing.

Anguil points out that manufacturing carbon fibre can have serious environmental ramifications and pose immediate danger to humans if careful consideration is not given to emission control at the production phase of these materials. As is the case with many industrial manufacturing operations, emissions are best destroyed through the use of thermal oxidation technologies but very few industries use custom designed abatement solutions like the carbon fibre processing industry does. Anguil has experience supplying systems for the destruction of hydrogen cyanide, silicone and nitrogen oxide (NOX) emissions often produced in the ovens and furnaces of carbon fibre plants. To treat the higher concentration exhaust streams coming from the carbon fibre furnaces, the company has designed a multi-zone Direct Fired Thermal Oxidiser (DFTO) whereby the nitrogen compounds are disassociated at high temperatures in an oxygen depleted chamber. The remaining gases are quenched before moving into a secondary zone where total emission destruction efficiencies are over 99% with minimal NOX generation.

For the higher flow, lower concentration oven exhaust Anguil manufactures a Regenerative Thermal Oxidiser (RTO). This type of oxidiser is capable of 98-99%+ destruction efficiency with very low operating costs. With achievable thermal efficiencies over 96% the RTO is capable of operating with little to no supplemental fuel use.

Armacell Benelux SA Stand number: V12 Website: www.armacell-core-foams.com

Armacell produces PET foam cores for the composites industry and claims to be the first to succeed in foaming high quality, bottle-grade PET on an industrial scale and qualifying PET foams for the composite industry.

At JEC, Armacell is launching its new lightweight product range of 60 kg/m3 that combines low density with the properties of the successful product families ArmaFORM PET AC, PET FR and PET GR. With this product addition, Armacell says it is the first to offer a complete portfolio of low density PET foam cores:

- ArmaFORM PET AC60: light, stable and extremely strong, for use in a variety of areas;

- ArmaFORM PET FR60: best in class fire properties (NF F16-101 (M1/F1); DIN 5510, FAR25.853) for weight sensitive applications with stringent flame, smoke and toxicity requirements; and

- ArmaFORM PET GR60: made of 100% recycled PET packaging waste, ideal for ecological concepts.

Like all ArmaFORM PET foams the new 60 kg/m3 density range shows:

- superior mechanical properties, excellent compression strength and high shear modulus;

- outstanding fatigue resistance for maximum lifespan;

- easy to shape by thermoforming (3D), offering freedom in design;

- high processing temperature of 150°C (short-term curing temperature up to 180°C);

- excellent thermal insulation properties;

- fine and closed cell structure for limited water & resin absorption (no corrosion or degradation over time; and

- 100% recyclability for enhanced ecological footprint.

Ashland Stand number C45 Website: www.ashland.com

Ashland offers a full package of resins, adhesives and gel-coats for wind turbine blade construction. Derakane™ 601 epoxy vinyl ester resin saves time and money by shortening moulding times compared to epoxy resins, the material of choice for many wind blades today. Based on available data, a blade manufactured with Derakane 601 can perform on par with epoxy blades, with the advantage that Derakane is not only more cost efficient, but also cures much faster. An Ashland presentation on Wind energy composites: Development and use of resins, gel-coats and adhesives will take place on 13 March at 1 pm on stand J34.

Ashland will also present Ashland's Maxguard™ - Third generation low emission gel-coat on 12 March at 1 pm on stand J34. This presentation will focus on Maxguard’s success in marine, transportation, sanitary and wind applications. It will also introduce the third generation of low emission Maxguard gel-coats and their excellent UV resistance, low water absorption and mechanical properties.

Underlining its long-term commitment to the European structural adhesives market, Ashland Performance Materials plans to open a new production facility for structural adhesives at its Kidderminster site in the UK in spring 2013. Some of Ashland’s structural adhesives will be presented in the technical paper Bonding solutions for lightweight structures on 13 March during the Automotive Conference of ICS. The paper will focus on different aspects of composite and hybrid bonding of parts for automotive and truck assemblies, and how engineered structural adhesive technologies are addressing these needs.

Barrday Stand number A31 Website: www.barrday.com

Barrday Inc is displaying its portfolio of thermoplastic materials tailored for the aerospace, military/defence, protective and energy markets, including unidirectional (UD) tapes, powder coated semi-pregs and pressed laminates.

Barrday manufactures UD aramid prepreg for the soft and hard armour markets based on proprietary thermoplastic resin technology. This material consists of two or four layers of cross-plied unidirectional product. Barrday has been investing in this technology for several years and will be introducing several new products at JEC. The company recently extended this technology to UD thermoplastic tapes targeting structural applications in the commercial aerospace, military/defence and industrial markets. These products utilise carbon and high performance glass reinforcements in PEEK, PEKK, PEI, PPS and nylon matrices. The tapes are available in a wide range of fibre areal weights and resin contents. Initial tape widths will be 160-305 mm (6.25-12.0 in), however the equipment has been sized to produce prepregs at widths up to 610 mm (24 in).

Barrday thermoplastic composite semi-pregs are offered at widths of 500-2,200 mm (20-86 inches). It can process a wide array of fabrics and engineered thermoplastics with its powder coating capability including PEEK, PEKK, PPS, PE and PP at resin areal weights up to 700g/m2. A variety of powder coated fabrics are available or under development ranging from lightweight glass veils to aramid and structural carbon fabrics. Powder coated fabrics are available in semi-preg or pre-consolidated laminate form.

BASF Stand number G17 Website: www.basf.com

BASF will exhibit a wind turbine and a blade profile, a fender demonstrator, a spoiler and a roof module. New materials include a PET (polyethylene terephthalate) based foam with the trade name Kerdyn® as well as new epoxy and PU (polyurethane) systems that can be used to produce composite parts by means of resin transfer moulding (RTM) processes.

With the aid of its multi-material Lightweight Composite Team, BASF is investigating composite concepts for the body and chassis of motor vehicles. The three plastic matrix systems based on epoxy resin, PU and polyamide, together with continuous-fibre reinforcement as well as high-volume processing by means of resin injection methods, especially RTM, provide the basis. Using a test component in the form of a carbon fibre-reinforced fender demonstrator, BASF will be exhibiting the new epoxy resin Baxxodur® System 2220 which was developed specifically for high-pressure RTM. The polyurethane side will be represented by a spoiler with RTM insert produced from the new Elastolit® R 8800. Both thermosetting resins employ novel curing mechanisms, allowing them to cross-link quickly. The transparent epoxy resin Baxxodur System 2220 offers a demoulding time of only 2.5 minutes at 120°C while offering a high resin toughness. The custom formulated polyurethane system RTM Elastolit R 8800 is compatible with all established fibre sizings and offers exceptional fatigue strength. Its damage tolerance is also very high. Both new resin systems have a wide processing window and can be demoulded easily, through incorporated matched processing aids.

The convertible roof module being exhibited serves to demonstrate new concepts and BASF's versatile materials for the RTM process as well. The sandwich component, which was developed together with EDAG GmbH, consists of a closed-cell polyurethane foam core between two carbon fibre-reinforced skin layers. With a total weight of 2.9 kg, the roof segment achieves a 40% weight savings compared to an aluminium counterpart and more than 60% compared to a steel counterpart. Possible applications for such material and processing combinations include, in addition to attached parts such as doors, trunk lids and roof modules, structural vehicle components subjected to high loads as well.

At JEC, BASF will introduce a structural foam based on PET. The new material with the trade name Kerdyn is a high-performance foam supplied in form of panels that is used inside wind turbine rotor blades, providing additional stability. As core material, PET foams offer exceptionally good mechanical properties and have a wide range of compatibility in terms of processing. With its ability to withstand very high temperatures and its very good chemical resistance, Kerdyn is extremely well-suited for use in composites. High-quality PET foam panels are also in demand in the transportation, marine, and building/construction sectors.

BASF will present the cross-section of a wind turbine blade that was manufactured using the range of BASF products available for blade production: The glass fibres are embedded in a Baxxodur epoxy resin system, the Kerdyn structural foam provides stability, the paint finish is based on a RELEST® gel-coat system and the semi-structural Elastan® polyurethane adhesive comes from the BASF product line too.

For vacuum infusion of ever larger rotor blades, BASF has developed the Baxxodur System 5100 consisting of Baxxores® ER 5100 resin and Baxxodur® EC 5120 hardener. This new low-viscosity system results in fast and complete impregnation of the fibres, but additionally offers a considerably longer processing time than standard systems. The company will also introduce a new epoxy resin-based structural adhesive system: the Baxxodur 4100 system consists of Baxxores ER 4100 adhesive resin and the standard Baxxodur EC 4110 hardener or alternatively Baxxodur EC 4105 for fast bonding. The system has been certified for blade production by German Lloyd.

For protecting rotor blades from erosion and UV radiation the company offers two RELEST Wind In-mold Gelcoats. The semi-transparent two-component materials are easy to sand and easy to use thanks to a coloured hardener component with mixing control function. Integrated UV absorbers prevent damage to the substrate from UV light.

The in-mould primer RELEST Wind Gelcoat Transparent can be applied to a film thickness of up to 400 µm. RELEST Wind ProcessCoat offers the benefits of an in-mould gel-coat at considerably lower usage. Both products are VOC-compliant and easy to process.

Cato Composite Innovations BV Stand number J70 Website: www.catoci.com

Cato Composite Innovations focuses on the development and manufacturing of thermoplastic composite components and parts. Recently, the helmet manufacturing technology and equipment from Cato Composites Norway was integrated into the company’s facilities in Doesburg, the Netherlands.

For series of sizes varying from 1000 products to up to 1,000,000 products per annum, Cato provides a development and manufacturing solution for monolithic, forged, sandwich and hybrid parts made from thermoplastic composite materials. For making hybrid components from endless fibre reinforced thermoplastic composites and injection moulded parts, Cato uses injection moulding production facilities on site.

As co-founder and former shareholder in Bond-Laminates GmbH and with over 20 years of experience in thermoplastic composite materials, product design and processing, Cato can select and specify the right material (fibre and matrix) at price points starting from €5/kg and specifically for an application. Cato’s machine park includes 11 injection moulding lines as well as seven thermoplastic composite production presses.

CDI Stand number W84 Website: www.centurydesign.com

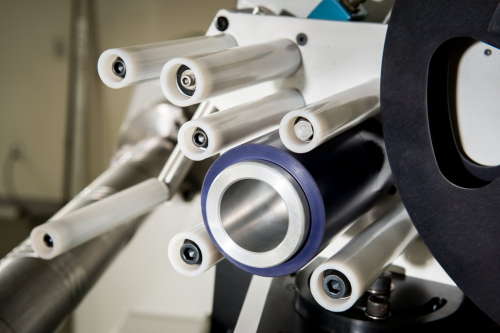

CDI (Century Design Inc) will launch the M777 Horizontal Tape Placement Machine, which offers precision tape placement on small to large diameter straight and tapered mandrels. The specially designed placement head controls both the tension of the tape as well as its accurate positioning on the mandrel, ensuring that standardised, high quality tubular components are produced every time.

The development of this machine was driven by customers looking to improve manufacturing methods for tubular structures such as golf shafts, fishing rods, bike frames and struts. Traditionally these parts have been produced by rolling or filament winding, and whilst these methods produce good results, they do not yield the most efficient parts due to ply drop offs and varying resin contents.

With a pitch up to 152 mm the M777 can process a variety of parts with a full range of materials and sizes. It also has the ability to wrap both prepreg and thin film tapes from the same tension head which in turn allows parts to be completed on one machine. This eliminates the need for a secondary operation which is time consuming and incurs further cost.

Key features of the M777 include: full 4 axis of motion; computer controlled with HMI touch screen and precision servo drives; full pivoting tape placement head with 180 degrees of motion; dual tension control to facilitate precise regulation of both small and large rolls as well as varying tape widths and materials; tension cancelling feature to allow for wrapping of long and/or small diameter parts; and capable of wrapping parts up to 300 mm in diameter.

CDI has already conducted successful trials on the M777 in partnership with a selection of customers.

Componeering Inc Stand V8 Website: www.esacomp.com

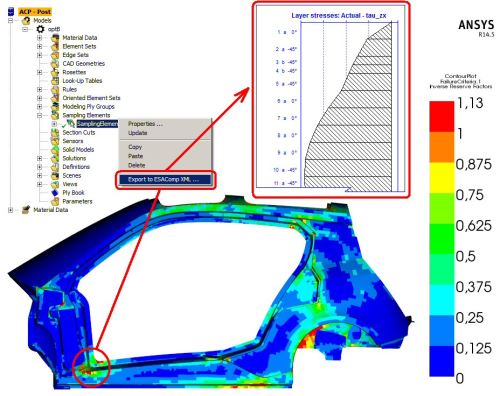

Componeering will demonstrate the new 4.4 version of its composite design and analysis software ESAComp. The new release includes improvements including: update and expansion of the materials database; new analysis features; and enhancements in the interfaces to other simulation software (ANSYS and HyperWorks by Altair). The most noteworthy among the new features is the nonlinear analysis for accurate consideration of large deformations in panels and cylinders. This makes advanced finite element analysis easily available in the early stages of the design process and hence helps achieve mass savings by avoiding overly conservative design approaches.

ESAComp 4.4 also debuts an enhanced interface with ANSYS Composite PrepPost (ACP). Sampling point laminate and load data from ACP can be read in ESAComp to allow detailed laminate level analyses, design improvements and reporting using the ESAComp tools.

Delcam Stand number L25 www.delcam.com

Delcam will demonstrate the latest developments in its PowerMILL software for the programming of machining by robot. It will use a KUKA robot, a combination that has proved successful for Delcam customers such as marine manufacturer Southern Spars, which found a robot to provide a lower-cost alternative to machine tools for the manufacture of larger composite components.

The new robot machining interface in the PowerMILL CAM software makes it easier to program robots for a much wider range of applications. Delcam says the ability to program the robot offline from 3D CAD data is faster and more efficient than the ‘teach and learn’ approach often used to create instructions for the equipment. This easier programming allows composite manufacturers to take advantage of the many potential benefits of using robots. Firstly, the cost of installing a robot is less than the price of a large machine tool with a similar working envelope, and secondly, the flexibility of the robot means that complex operations can be carried out in a single set-up, so cutting production times and reducing the number of fixtures needed.

Robots do have disadvantages, Delcam admits, since they struggle to machine harder materials and cannot match the tolerances possible with modern machine tools. However, they can be used successfully in any area where softer materials need to be machined to accuracies of tenths of a millimetre. This can be more than adequate for components that might be several metres in length, as is often the case for composite tooling and parts for marine, aerospace, autosport and rail applications.

Delcam will also demonstrate its SHAPE design software and PowerMILL five-axis machining system, which are used for the design and manufacture of models, patterns, moulds and fixtures for component manufacture, and for the finish machining of parts.

Dow Chemical Company Stand number P14 Website: www.dow.com

Dow is presenting its next generation VORAFORCE™ Composite Systems, along with further products designed to create stronger, lighter and more durable composites for construction, infrastructure, transportation and other applications. Visitors can learn more about: new products for pultrusion and filament winding; next-generation infusion technology for wind blade composites; a fast-cure, composite resin for automotive solutions; and manhole covers made with Dow technology.

In addition, Dow’s new carbon fibre joint venture DowAksa will exhibit on stand number K45.

Elantas Italia Stand number J7 Website: www.elantas.it

Elantas Italia, part of the ALTANA group of companies of Germany, supplies epoxy and polyurethane resins and epoxy adhesive for the production of composites, tools and moulds. The company’s resins are used in marine (wet lay-up and infusion), automotive and wind turbine blade applications, as well as for pultrusion and filament winding, rapid prototyping, and for moulds for high temperature use. The company also manufactures a range of tooling boards, silicone resins, glass fabrics, fillers, release agents and wax.

Elantas Italia is seeking a distributor with knowledge of the composite tooling market.

Fontijne Presses Stand number C52 Website: www.fontijnepresses.com

Fontijne Presses has more than 80 years of experience in manufacturing hydraulic laboratory platen presses. Its products are being used in the composites, polymer processing, rubber, laminating/wood and aircraft industries as sample preparation equipment for R&D, materials development and quality control. The company recently introduced a new and in-house developed control system for its presses.

Fontijne Presses offers a variety of options for the composites industry. Small production runs, samples for material development and testing, and thermoplastic composites can be made on the presses. To prevent air in thermoplastic composites, the company has developed high temperature vacuum presses to prepare samples like PEEK, PPS, PEI and PEKK. A control is built into the press to ventilate the vacuum chamber after pressing. Fontijne Grotnes provides vacuum presses in the range 50-1000 kN, with heated platens of 225-500 mm. Each press is equipped with a touch screen control system for temperature and force. The standard manual control has a basic user interface; this can be extended by the modified programmable and PC control system, the Lab Pro-View.

FORMAX Stand number L76 Website: www.formax.co.uk

FORMAX, a manufacturer of carbon fibre and speciality composite reinforcements, will be announcing expansion plans and a new company organisation.

The new organisation will involve the creation of three business sectors for the marine, automotive and industrial markets. This will ensure customers receive a highly specialised service, as each division is supported by technicians and sales staff with market specific skills and expertise. The company will also expand its production facilities in Narborough, UK, through the acquisition of a 2000 m2 site to house an additional manufacturing plant and composite testing equipment.

FORMAX will also be investing considerable resource into its R&D functions. A Knowledge Transfer Partnership (KTP) with Nottingham University, UK, commences in Spring 2013 with the aim of developing a comprehensive material characterisation capability and advanced simulation methodology for composites. Other areas of research include the recycling of waste carbon fabrics into short fibre products for use in tooling laminates, carbon ceramics and structural composites; and the elimination of fabric waste in future composite manufacture.

Future Fibres Stand number X20 (Spanish Pavilion) Website: www.futurefibres.com

Composite rigging manufacturer Future Fibres will highlight its wide range of composite products for rigging, spars and booms for all types of grand prix racing, super-yachts and performance yachts.

CEO Hugues Jacquemin says that although the marine sector is central to Future Fibres’ success the recent contribution, development and manufacturing of cables for use in a high-tech composite footbridge clearly highlights the company’s intentions to expand into other industrial sectors. The company is already involved in projects in civil engineering, military and Formula 1 racing across the world and sees great potential for its products in other industrial sectors such as in cranes, hoisting and lifting equipment.

Future Materials Group Stand number D70 Website: www.futurematerialsgroup.com

UK-based consultancy Future Materials Group (FMG) is the brainchild of David Schofield and Adrian Williams, both experienced veterans of the composites/advanced materials sectors. The company operates globally, providing clients in the advanced materials and high value manufacturing sectors with support to achieve their ambitions for growth – from growth strategy development and growth acceleration planning, to managing mergers and acquisitions, developing strategic partnerships and mobilising finance for growth.

With 25 years in advanced materials, David Schofield has worked internationally in both executive and non-executive roles, for Ciba-Geigy, Huntsman and Gurit AG, among others, providing extensive advice on strategy, marketing, business development and acquisitions for multi-nationals and SMEs. Adrian Williams has held a number of senior executive positions in the UK, Europe and North America, specialising in growth strategy and implementation for companies at every stage of their development, from start up to large, multi-nationals around the world. James Austin has also recently joined the team. With over 20 years’ experience in composites/advanced materials, Austin was instrumental in transforming SP Systems’ market position prior to the company’s acquisition by Gurit AG, where he remained as COO with responsibility for supply chain and production in Europe, Asia and North America.

GMS Composites Stand number Z38 Website: www.gmsindustrial.com.au

GMS Composites is showcasing its latest high performance epoxy prepreg, GMS EP-620, which has been developed for the cost effective manufacture of composite parts needing very high fracture toughness and energy absorption in use.

The prepreg employs uses a tough, impact modified epoxy resin matrix system, developed by GMS Composites to be capable of high velocity ‘ballistic level’ high kinetic energy absorption and resistance to repeated shock impacts. According to GMS Composites, the GMS EP-620 epoxy prepreg resin has over 1.75x the fracture toughness and requires 3x the fracture energy to break compared with standard industry prepreg resins tested. The official data sheet for the neat GMS EP-620 system quotes fracture toughness K1C figures of 2.2 – 2.35 MPa√m and an ultimate elongation of 11%. Depending on the application, GMS EP-620 epoxy prepreg resin can be combined with reinforcement fabrics made from carbon fibres, aramid, s-glass or polyethylene fibres to mould components designed for ballistic protection, personal body armour and vehicle protection in a variety of demanding defence, military, industrial and motorsport applications.

Several successful ballistic and motorsport customer product trials took place during the development stage to thoroughly test and validate the mechanical performance of GMS EP-620; a variety of laminate designs and reinforcements for a number of demanding military and motorsport applications were trialled. This included a race trial by a leading Australian rally team, who carried out a comparative performance test. They replaced the originally fitted FRP composite underside protective covers with identical parts made from GMS EP-620 epoxy aramid fibre prepreg; front and rear underside composite protection covers are typically located beneath the engine, as well covering key safety critical parts under the car that must be reliably protected, such as the fuel tank, fuel lines and brake lines. Under arduous rally racing conditions the GMS EP-620 aramid fibre composite protector covers proved to have superior fracture toughness resistance by lasting twice as long as the original composite covers. GMS EP-620 epoxy prepreg resin has also been designed for cost effective production. It exhibits good flow characteristics during moulding and the tack level can be varied to suit individual conditions and requirements. It has a versatile curing cycle from 80°C up to 150°C; at the maximum 150°C processing temperature the resin has a gel time of 2-3 minutes and moulded parts can be fully cured within 20 minutes. This has the advantage for manufacturers of making it suitable for fabricating a wide range of shapes and sizes, from large complex structures to smaller FRP composite parts. The processing properties of the prepreg also enable fabricators to apply a range of pressures and ramp up rates depending on the design, size and laminate construction of the part being produced. GMS EP-620 epoxy prepreg has a reliable shelf life of over 6 weeks at 23°C ambient, up to 12 months if refrigerated at -18°C.

Information on the new prepreg is available on the stand (Z38) of Carbon Nexus, Australia’s leading centre for Carbon Fibre and Composites Applied Research.

Gurit Stand number K44 Website: www.gurit.com

Gurit, a supplier of composite materials, engineering, tooling, parts and systems, will be launching a new fire retardant epoxy wet laminating system capable of BS 4276 Class 1 flame spread resistance, and a new prepreg technology that does not require chilled storage.

Gurit will also showcase its products for high volume automotive body panel production using rapid press moulding to produce a Class-A finish capable of high temperature paint-line processing (also see page xx). Other products on display include a new fire retardant PET foam core material G-PET FR, and a new core sealing technology for balsa, UVOTECH, designed to significantly reduce resin uptake whilst retaining core-laminate adhesion and durability. Gurit will also promote its new sealing technology for PET and its Airstream™ coating technology, a specialised prepreg developed to enable the economic manufacture of very high quality unidirectional carbon spar caps without the requirement of a temperature controlled factory environment.

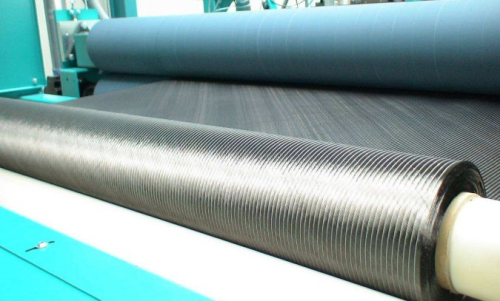

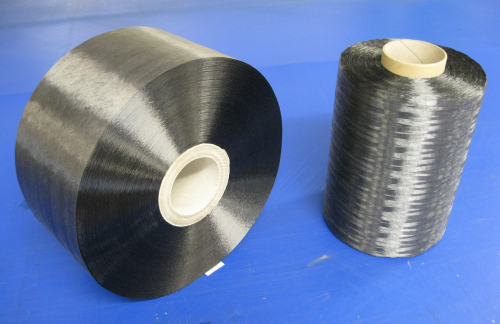

Hengshen Stand number V32 Website: www.hscarbonfibre.com

Hengshen Co Ltd, founded in 2007, is a vertically integrated carbon fibre composite materials manufacturer in China. Based on a 1,100,000 m2 site just west of Shanghai, and now employing more than 1400 people, Hengshen manufactures PAN precursor and carbon fibre, woven and non-crimp fabrics, prepreg and resin infusion systems. The company is privately owned and has invested in significant manufacturing capacity, with current production capacity at 3500t of carbon fibre, and further expansions underway. This manufacturing capability is supported by an R&D and Engineering Centre employing over 120 multinational staff.

Hengshen recently opened its new Technology Centre on Southampton Science Park in the UK, which will provide technical support to European customers in composite materials sales, design and collaborative development programmes. The company is also introducing a range of high performance carbon fibre prepregs and infusion systems, designed for demanding aerospace, marine, transport, energy and general composites applications, alongside engineering design services for customers new to composite part design.

Henkel Stand number R45 Website: www.henkel.com

Henkel will showcase the latest additions to its Frekote line of semi-permanent release agents, sealers and cleaners: Loctite Frekote CS-122 and C-400. CS-122 is a pretreatment product that is said to seal porosity exceptionally well. It forms a high-gloss coating within two hours and has minimal odour. C-400 is a water-based release agent that is particularly suitable for producing high-gloss coatings on polyester parts, e.g. for visually attractive vehicle spoilers, truck cabs and yacht bodies.

Henkel also offers a wide range of structural adhesives in five core adhesive technologies: epoxy resins, acrylates, polyurethanes, silane-modified polymers and silicones. Macroplast UK 1340 is a polyurethane (PUR) adhesive that makes wind turbine blade production more efficient and satisfies the specific mechanical requirements for use in the wind power industry. Polyurethane-based adhesives react quickly, which means that Macroplast UK 1340 cures much faster than the epoxy resins used up to now. This minimises the duration of the cure phase, but also the release of energy and thus the temperature during curing. (See Henkel PUR adhesive speeds up wind turbine blade bonding .)

Hexcel Stand number Website: www.hexcel.com

Hexcel’s new HexPly® M79 epoxy prepreg is said to offer a real option for those who currently manufacture blades by infusion to move to prepreg technology and benefit from superior mechanical performance. It is a lower temperature curing prepreg that cures faster than products currently available. For a very low temperature cure a cycle of 10 hours at just 70°C is recommended. This enables lower cost tooling and associated materials to be used and results in energy savings. If a more rapid cure is required then HexPly M79 cures in 8 hours at 75°C and in only 4-6 hours at 80°C. With HexPly M79 there is also much less risk of an exothermic reaction (a 60% reduction on Hexcel’s standard M9G prepregs) and it has a very long outlife at room temperature of at least 2 months. The low cure temperature means that the system is totally compatible with any liquid epoxy resin used for infusion processing so that the prepreg and infusion processes can be combined in the same blade.

Hexcel’s HexPly carbon fibre UD prepregs with Grid Technology have been certified by Germanischer Lloyd for use in wind energy applications.

Hexcel is also launching HiTape® high performance unidirectional reinforcements, based on its HexTow® carbon fibre and designed to meet the requirements for aircraft primary structures made by out-of-autoclave vacuum infusion or injection technology. HiTape allows dry preforms to be manufactured in a fully automated lay-up, similar to the AFP and ATL processes widely used for UD prepregs. Aircraft structures made with HiTape are reported to demonstrate mechanical properties as high as those found in parts made with the latest generation primary structure prepregs.

HiTape has been used by AeroComposit for wing prototype components and by Spirit AeroSystems to form the skin of an engine nacelle outer fan cowl. Video footage from Coriolis and M Torres shows the speed and efficiency of the HiTape lay-up process.

Huntsman Stand number G65 Website: www.huntsman.com/advanced_materials

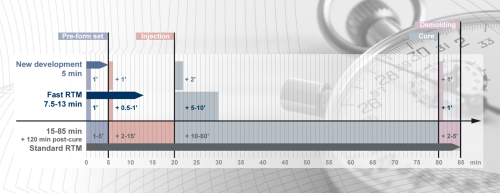

In the automotive composites sector Huntsman is meeting manufacturers’ demands for faster processing and shorter production cycles with its epoxy resin systems for high pressure resin transfer moulding (HP-RTM). Huntsman will showcase the latest Araldite system to enable five-minute production cycles. In comparison to first generation HP-RTM, this equates to a 30% time saving. The company will also highlight other fast curing epoxy resin systems including those that enable less complex compression moulding and the production of parts in less than three minutes.

Huntsman will also focus on its epoxy resins, hardeners and accelerators, which are designed to help formulators and prepreggers enhance the mechanical properties and overall quality of their systems. Tactix 742 and Tactix 556 are two resins that are said to offer the highest glass transition temperatures and the lowest water sensitivity achievable among all the epoxy resin systems commercially available today. Araldite MY 9721 and Araldite MY 0610 epoxy resins combine high thermal resistance and a high modulus with easier processing, thanks to their low viscosities. Hardeners and accelerators, including Aradur 3123, Aradur 1167 and other recently developed DDS-modified curing agents, complete the line-up, providing formulators with new tools to adapt curing kinetics of their systems while providing high thermal resistance.

Huntsman’s epoxy adhesives, which combine high toughness with lap shear strengths greater than 35 MPa, are proven in numerous applications. Araldite AW 4858/Hardener HW 4858, for example, is suitable for bonding composite to composite or composite to dissimilar materials and maintains high strength even under harsh environmental conditions. Araldite AW 4859/Hardener HW 4859, another epoxy adhesive on show, shares similar mechanical properties and is ideal for bonding structures that will be exposed to temperatures exceeding 80°C during their life, for example in racing car, aerospace or in general transportation applications. Huntsman will also show its fast curing methacrylate based adhesives Araldite 2047-1 and Araldite 2048, which have been designed respectively for composite bonding with limited surface preparation and for the creation of flexible joints with a 90% elongation at break.

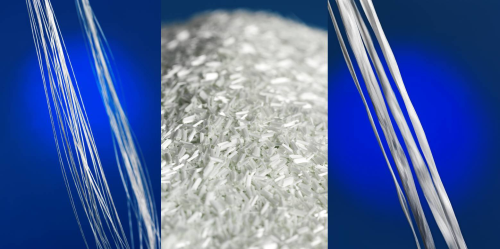

Johns Manville Stand number G46 Website: www.jmeurope.com

Johns Manville will present its new reactive glass fibres developed for improved performance in structural thermoplastic composites. Innovative products, such as StarRov® RXN 886, will be introduced for the in-mould caprolactam polymerisation process. The new product maximises glass-matrix bonding, resulting in improvements in strength, multiaxial impact, aging performance, and dimensional stability of polyamide 6 (PA 6) based structural composites. The product can be used in a variety of processes, including TP-RTM, TP-RIM, TP-pultrusion, and TP-filament winding.

Johns Manville will also present new applications where ThermoFlow® chopped strands are used in polyamides and polypropylene. Additionally, automotive applications using MultiStar® 272 roving for SMC and StarRov LFTPlus 490 contributing to lower odour LFT applications will be displayed. For the building and construction segment, high structural profiles using StarRov 908 roving will be shown.

Langzauner Stand number V73 Website: www.langzauner.com

One year ago Langzauner launched its new laboratory press, featuring a hydraulic drive with variable rotation speed. Because of its accuracy and versatility, many research and development companies are committed to this drive system. One of the system’s major benefits is its efficiency, which also makes it interesting for presses used for serial production. Avoiding the use of proportional valves enables the use of hydraulic oil of lower quality. Furthermore, the oil is only in motion when the machine is in action. This increases the lifetime of the oil and an oil cooler is unnecessary. The first presses for serial production, equipped with this system, are already in use. With a 650t press, driven in three shifts, a potential saving of more than €50,000 per year can be realised. This drive concept is therefore extremely interesting for companies in the automotive sector where mass production demands machines with low energy consumption.

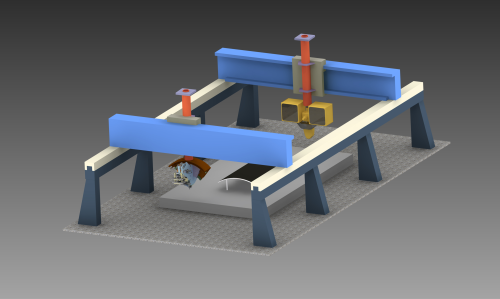

Mikrosam Stand number V80 Website: www.mikrosam.com

Mikrosam has already delivered automated tape laying (ATL) and automated fibre placement (AFP) machines around the world, and is now combining them into a single product, significantly easing the ability to program and lay-up parts. The new line of automated placement machines can apply both technologies – ATL and AFP – on a single mandrel, without complex and time consuming head switching. There is no downtime to change from one placement method to another, since both lay-up heads work independently of each other. Together with the MikroPlace programming software, the producer is able to program both technologies from a single PC and run the program on a single machine interface. The machines are offered either in the robust, gantry-style dual-lay-up head, or as a multi-robot lay-up platform for parallel processing.

Mikrosam also offers: automated lines for high-volume production (LPG and CNG tanks, pipes, drive shafts, composite insulators); advanced filament winding machines with up to 6-axes for complex parts, product development, and prototyping; filament winding machines with integrated fibre placement assisted head for thermoplastic roving; Winding Expert Software – advanced filament winding pattern development; prepreg making equipment (UD tape, fabric prepreg, slit-tape and tow preg); and slitting machines.

Momentive Specialty Chemicals Stand number G45 Website: www.momentive.com

Creating composite parts in 2 minutes is no barrier for Momentive’s new EPIKOTE™ Binder 05475 and EPIKURE™ 05500 fast-cure epoxy systems. Developed for resin transfer moulding (RTM) and liquid compression moulding (LCM) these products enables mass production of automotive composite parts.

Momentive is introducing the next generation of epoxy RTM systems through its EPIKOTE binder 04695-1 and EPIKURE 05490A curing agent. These new products deliver a minimum level of cure shrinkage, which provides a smooth Class A finish.

The new EPIKOTE Binder System 620 enables mass production of automotive composite in hot-melt preforming processes. The product is a one-component, cross-linkable powder binder that can be applied to carbon or glass fibres and fabrics as a powder using a hot-melt coating process line.

Oxeon Stand number P25 Website: www.textreme.com

Oxeon is celebrating 10 years in business. The company produces spread tow carbon reinforcements under the TeXtreme® brand.

TeXtreme reinforcements are designed for making ultra-lightweight composites. The technology is flexible and tow-size independent which enables development of optimised reinforcement solutions tailor-made for specific application needs. Utilisation of TeXtreme spread tow carbon fabrics and carbon unidirectional (UD) tapes by manufacturers of advanced aerospace, industrial and sports products confirms that 20-30% lighter composite parts can be produced with improved mechanical properties and superior surface smoothness.

PGI Stand number N75 Website: www.pgi-industrial-europe.com

PGI Industrial Division manufactures nonwovens for the FRP industry. Products and applications include:

- synthetic veils;

- filament winding (pipes, fittings...), giving corrosion resistance properties and better finishing;

- pultrusion, to produce resin rich surface, giving UV, corrosion and cosmetic additional properties;

- interlaminar veils (allowing better adhesion between two different layers);

- RTM : Finishline 65; and

- core material for laminates: Matline+N used as a print through blocker as well as a core to get thickness at reduced cost. Compatible with polyester, epoxy and vinyl ester.

Reichhold Stand number B63 Website: www.reichhold.com

Reichhold has acquired in-house capabilities to perform cradle-to-gate LCA (life cycle assessment) studies for a variety of its resin systems in order to support customers’ efforts to manufacture more sustainable products. The level of emission and environmental impacts of Reichhold’s resins for which LCA and LCI (life cycle inventory) studies have been made are considerably lower than the LCIs of a ‘general polyester resin’ in the most widely available LCA software and database. This is due to better process efficiency, optimised raw material sourcing and optimised management of energy requirements. As a result the LCA study for the final composite products incorporating Reichhold’s resins will often show lower environmental impacts which will provide customers with data to promoting their products versus competitive materials (thermoplastics, aluminium and steel, wood, concrete) and when implementing eco-labelling schemes, making environmental claims or developing Environmental Product Declarations.

LCA and LCI studies have already been made for a wide range of Reichhold’s products and the LCA model is being systematically expanded to include all Reichhold products.

SCIGRIP Stand number D43 Website: www.scigrip.com

Adhesives supplier SCIGRIP is launching a product for bonding dicyclopentadiene (DCPD) composites. As a result of its developmental work with SG600, a methyl methacrylate (MMA) structural adhesive, SCIGRIP has produced a product suitable for bonding many difficult substrates including grades of DCPD. Many grades of DCPD adhered successfully with SG600 without time consuming preparation techniques such as flame treatment. The adhesive is cold curing to produce tough and fatigue resistant bonds and also features ratio adjustable cure times and rheology compatible with robotic application. SG600 has also performed well in trials bonding ABS, PVC and SMC as well as traditional polyester, vinyl ester or epoxy composites.

SCIGRIP will also feature its 10:1 MMA range, now in full EU and USA production. This includes SG230HV, the high gap fill low exotherm MMA for large composite component assembly, and SG300, popular in many transport sectors for tough bonding of composites and metals without primer.

“We are listening to our customers: they need to eliminate or reduce costs in their preparation, application, and cure or post-cure processes,” says Peter George, Sales and Marketing Director of SCIGRIP Europe. “They are seeking automated, efficient and reliable bonds with impact resistance and good fatigue performance without heat curing. Our customers continue to upgrade the substrates they wish to work with and this provides us with an opportunity to develop and demonstrate the most effective adhesives solutions to suit.”

Scott Bader Stand number V18 Website: www.scottbader.com

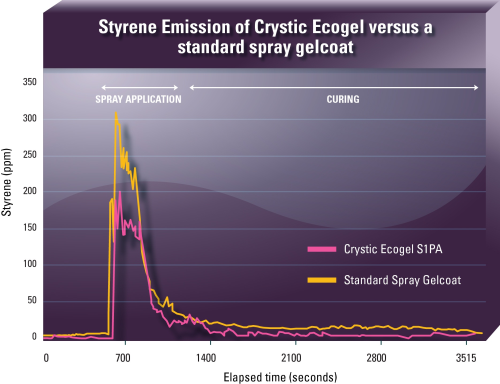

Scott Bader will showcase its new ‘ultra-low styrene content’ spray gel-coat Crystic Ecogel S1PA. The company says that Ecogel S1PA has been independently laboratory tested and proven to be able to cut total styrene emissions by over 55%. It has also been extensively tested by a number of customers including LM Wind Power, whose senior manager for global equipment engineering Dan Lindvang states: “LM Wind Power now uses Scott Bader's ultra-low styrene gel-coat products in its plants globally. We have seen a major reduction of more than 50% in styrene emissions during spray gel-coat application, without any loss of performance and using the same standard spray equipment and catalysts as with conventional gel-coats. The use of Scott Bader's ultra-low styrene Ecogel gel-coats has enabled LM Wind Power to greatly improve the environment for our workers and meet our own demanding in-house HSE standards."

Scott Bader is also launching a new vinyl ester spray tooling gel-coat, Crystic Gelcoat 15PA, which offers superior gloss retention, and will be promoting the new high performance Crestabond M7-05 and M7-15 grades, which extend its primer-less methacrylate structural adhesives range with 1:1 ratio as well as 10:1 ratio Crestabond product. The two 1:1 ratio grades are said to be particularly good at bonding galvanised metal and other difficult to bond metals and plastics with no need for a primer, and have higher elongations than competitive adhesives products with superior adhesive performance.

Scott Bader will also showcase its Crestapol acrylic resin range, with a special feature on a new flexible thin GRP pipe fabricated by filament winding fibreglass with Crestapol 1250LV. Crestapol 1250LV has been developed to also exhibit excellent performance with standard sized carbon fibre, and Crestapol 1250LV CFRP parts will be exhibited on the stand, including a wind turbine blade. Crestapol grades suitable for closed moulding and pultrusion will also be on display.

United Initiators Stand number J26 Website: www.united-initiators.com

United Initiators GmbH acquired Syrgis Performance Initiators in July 2012, expanding its product range and geographic coverage. With company headquarters and plant in Pullach, Germany, and with further production facilities in Sweden, the US, China and Australia thermoset customers will be offered a complete product range throughout the world.

United Initiators has taken a leading position in organic peroxides for the thermoset market with a complete product range for all applications and production techniques. Its products for room- and elevated temperature curing systems include: ketone peroxides; peroxide mixtures; hydroperoxides; diacyl perxoxides; peroxyesters; peroxyketals; and peroxydicarbonates.

Wabash MPI and Carver Inc Stand number Z73 Website: www.wabashmpi.com

Wabash and Carver manufacture presses for the composites industry with press capacities ranging from 0.5 to 1200 tons and platen sizes from 6" x 6" to 6’x 12’. In The Demo Zone a Wabash G100 press will be part of a demonstration featuring composite induction heating technology. RocTool, a moulding technology company, will be supplying the mould running in the Wabash press.

In addition to composite moulding presses, Wabash MPI also offers standard and custom hydraulic, electric and pneumatic presses for compression moulding, vacuum moulding, ASTM testing, laboratory and R&D applications.

Carver Inc offers two-column and four column benchtop, manual and automatic hydraulic laboratory presses suited for various materials.

Wessex Resins & Adhesives Ltd Stand number W83 Website: www.wessex-resins.com

Wessex Resins & Adhesives is introducing Six10 epoxy adhesive. The new product meters the correct ratio of epoxy resin and hardener from a multi-chambered tube that dispenses from any standard caulking gun. Six10 offers permanent, waterproof, gap filling and gluing performance that is expected from a marine grade epoxy adhesive, in this easy to dispense package. The pre-thickened components pass through a static mixer in which they are fully blended together before being dispensed in a smooth workable bead of epoxy. Working time is 45 minutes at 21°C and solid cure in 5-6 hours. ♦