Wind and solar power are well established and, as their commercialisation continues apace, there is a degree of technology convergence in each case.

This is not the case with wave and tidal power, where the field for fundamental innovation is still wide open. Ideas range from the straightforward to the fanciful and, although several concepts are in pilot and demonstration phases, commercialisation is still some way off for most. Wave power, in particular, is still characterised by diversity and experimentation.

Here we outline some of the prevailing concepts and give an example of each.

Surface point absorber (buoy)

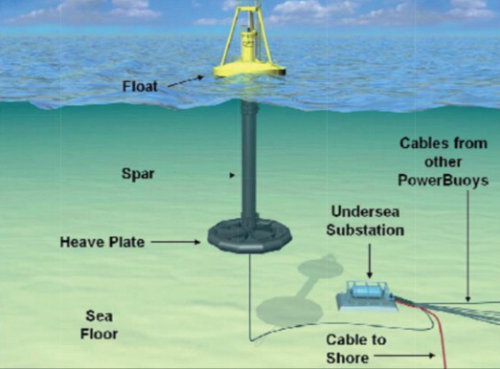

Buoy-based solutions, also called “surface point absorbers,” come in several guises and rely on the differential motion between a floating buoy (which rises and falls with the passage of waves) and a base resting on the sea bed. The two elements are joined by a mechanism that converts the kinetic energy due to the buoy’s motion into electrical energy. A notable example of this approach is the PowerBuoy® system from Ocean Power Technologies, which utilises a sliding spar and power take-off approach. As the buoy contours the waves, it rises and falls inside a cylindrical tube which terminates in a weighted element on the sea bed. In doing so, it causes electricity to be generated via a power take-off and generator. In ocean trials carried out off Scotland in 2011, an OPT Mk3 system incorporating a simulated grid connection proved able to maintain generation, averaging over 400kW, in waves ranging from slight to very high in storm sea states. A peak capacity of 866kW was recorded. This ocean test run of a third-generation system followed previous trials of earlier models. A prototype utility PowerBuoy deployed at a US Marine Corps base in Hawaii was the first grid-connected wave energy device in US territory. Another prototype, developed with support from the US Navy and utilities in New Jersey, was trialled in the period 2005-08; yet another trial took place off Spain. Results from these early deployments led to the OPT Mk3 that featured in the arduous Scottish evaluation. Surface point absorbers have been a strong development focus and other devices include CETO Wave Power’s Aqua buoy (Australia), the Flansea (Flanders Electricity from the Sea) device (Belgium), the SE Sea Waves Power Plant (Israel), the OE Buoy from Ocean Energy (Ireland), the Wavebob (Ireland), Sea Raser (UK) and Upsala University’s Lysekit Project (Sweden). Differences between these lie mainly in the way kinetic energy is converted to electricity, with various arrangements of piston pumps, linear generators, turbines, etc.

Multi-point absorber

As the name suggests, a multi-point absorber uses multiple floats instead of a single buoy. These are attached to a fixed platform that is standing on the sea bed via legs. Wave-induced up-and-down motion of the floats is converted to angular motion in the arms that connect to the floats to the platform and thence (via power take-offs) into hydraulic power which drives a generator. Advantages over a single point device include smoother power delivery, since the spaced floats experience passage of a wave at different times, higher aggregate power and redundancy in case of failure at any given float. In addition, the platform can be used to support a wind turbine so that combined wave and wind power generation is possible. A two-float prototype Wave Star machine from Wave Star Energy A/S in Denmark has exported electricity to the grid since September 2009. Currently the device is being extended so that more power can be generated when it is redeployed. A much larger machine with up to 20 floats is planned. Wave Star incorporates a storm protection system under which floats are automatically raised out of the water in high sea states.

Attenuator

An attenuator comprises two or more floating elements that are hinged together in a “chain” which is aligned at right angles to the waves. As a wave passes beneath and along the chain, the elements move in the vertical plane such that their hinged joints rise and fall creating a constantly varying angle between each pair of elements. This angular motion is captured by power take-off struts and converted (via hydraulically driven generators) to electricity. In extracting energy from the waves, the device also reduces their amplitude — that is, it attenuates them.

The best known example, and arguably the nearest to becoming commercial, is the Pelamis Wave Energy Converter from Pelamis Wave Power in Scotland. In a Pelamis device, the elements are cylindrical floats that are linked by articulating joints. The first Pelamis deployment at sea took place in 2004 at the European Marine Energy Centre (EMEC) off Orkney, Scotland. A derivative machine deployed off Orkney six years later was claimed as the world’s first wave energy device to deliver electricity from an offshore WEC to an onshore grid. In 2008 the world’s first multiple machine wave farm was commissioned, off Agucadoura, Portugal, with three Pelamis machines giving 2.25MW total capacity. This farm was subsequently decommissioned for corporate financial reasons.

Currently, Pelamis Wind Power is involved in a joint venture with Vatenfall to develop a project off the Shetland Isles that would deliver power to the mainland via an HVDC link. Another part of this wind and wave-rich area, the Outer Hebrides, could be in line for Pelamis power, too – given that there are plans with Lewis Castle College and an industrial consortium to field a 10MW, 14-machine farm 10km off Lewis. A further Pelamis farm could be deployed off Scotland’s north coast, specifically at Farr Point, Sunderland, where Pelamis Wave Power has a seabed lease option. Richard Yemm, founder and CEO of Pelamis Wave power, believes that 15 years of development that have seen six full-scale machines deployed, collaborative work with power utilities since 2005 and more than 10,000 hours of at-sea grid-connected experience, have opened up real commercial prospects for Pelamis. The Scottish government seems to agree, having last autumn awarded a share of its Marine Renewables Commercialisation Fund to the company to support further progress, including the development of an enhanced version of Pelamis. This adds to a £1.4m award from the Energy Technologies Institute to fund further development and trials.

Oscillating wave surge converter

Basically, a buoyant flap or plate is attached to the near-shore seabed by a horizontal hinge that allows it to pitch down towards the horizontal when a passing wave exerts surge pressure, and become vertical again — under its own buoyancy — once the wave has passed. The continual oscillating motion caused by the passage of waves is used to drive a pump which pushes water through a hydro-electric turbine. Championing this oscillating plate approach is Edinburgh-based Aquamarine Power Ltd with its Oyster WEC. Oyster is designed to be located in depths of 10-15m, typically about half a kilometre from the shore. A double-acting hydraulic pump operated by the pitching motion of the device pushes water through a pipeline to a turbine ashore where electricity is generated. Keeping the turbine ashore (together with its power take-off and control system) keeps them out of the aggressive near-shore marine environment, prolonging life and facilitating operational adjustments and maintenance. A 315kW proof-of-concept first-generation Oyster was deployed in 13m of water at EMEC in 2009. This has subsequently been replaced by a later improved model, the Oyster 800. Aquamarine CEO Martin McAdam reports that following an extensive product improvement programme intended to strengthen the device against the ravages of the sea, the resident Oyster had notched up 6MW of delivered power in 60 hours of operation by November. The present trials programme should lay the groundwork for a further-developed Oyster 801 successor, which will be a major milestone on the path to a fully commercial model.

Oscillating water column

This type of device is a civil engineered structure which can be set into a seaside rock face, or placed in a near shore or offshore location. A large wave capture chamber is connected to a column in which the water level rises when a wave enters the chamber. This compresses air at the top of the column, pushing it through an air turbine to generate electricity. Once the wave has passed, air re-enters the chamber ready for the next wave-induced compression cycle. A popular type of turbine for this application is the Wells turbine, which is driven both when air is expelled from the column and in the reverse flow when it re-enters. The turbine always rotates in the same direction, resulting in optimum energy harvesting.

It seems that the first working OWC was constructed in 1910 by Frenchman Bochaux-Praceique to light and power his house near Bordeaux. However, a more modern exponent is Australian company Oceanlinx which has – with the help of considerable Australian and international funding – spent the last decade developing its OWC technology to the point where it has currently reached Technology Readiness Level 7 with Level 8 as the next aim, denoting commercial readiness.

Advantages claimed for its technology include no moving parts below water to be choked up with marine organisms, hence low and simple maintenance. Environmental intrusion is minimal, there are no emissions, and a deep sea OWC can be made part of an artificial reef. Use of a specially developed Denniss-Auld bi-directional air turbine, in which the only moving part is above water, facilitates both electricity generation and sea water desalinisation to produce fresh water.

Oceanlinx's first full-scale prototype was the near-shore (GreenWAVE) device it operated at Port Kembla near Sydney from 2005 to 2009. Knowledge gained led to the world's first 1MW rated wave energy converter, this GreenWAVE unit having being launched last October.

Earlier, a Mk 3 Pre-Commercial device which operated during early 2010 was one of the first floating deep sea (“BlueWAVE” in Oceanlinx parlance) OWCs to be grid-connected. Unfortunately, this system was torn from its moorings and wrecked in a storm the same year. Imminent placing and operation of a similar unit off South Australia will constitute a fully realistic test of the viability of the technology as a commercial proposition. The device in question is designed for a 25-year service life and to meet the Technology Readiness Level 8 target.

Overtopping device

Waves break over a wall, creating a head of water in the storage reservoir beyond. Releasing this water back into the sea via a turbine enables electrical power to be generated.

Wave Dragon, an example of the principle conceived by a Danish inventor, utilises large wing extensions to capture part of a wave and focus its passage up a ramp and into a floating storage reservoir. From there, water is gravity fed through water turbines (similar to those used in low-head hydroelectric power stations) back to the sea.

A reduced-scale (about a fifth) prototype located off North Denmark provided more than 20,000 hours of test operation from 2003. (It was claimed to have been the world‘s first offshore WEC.) Based on this experience, larger demonstrator systems of 1.5MW, 4MW and 7MW are in various stages of discussion and planning. Additional Concepts

There are other ideas in different states of play. A submerged pressure differential device, for example, is a fully submerged installation that captures energy from the change in pressure induced in the top of the device as a wave moves over it. Another way to capture energy is to mount an eccentric weight on a vertical axis, around which it is free to rotate. This assembly is contained within a bowl-shaped floating capsule which makes complex movements in response to the waves. The wave-induced motion causes the weight to start a rotation, which is then maintained by the weight's inertia. The rotating mass drives a generator.

Then there is the submerged rotor approach, sometimes referred to as cycloidal wave energy conversion. Atargis Energy Corporation (USA), for instance, has been tank testing a submerged 20m diameter rotor with two hydrofoils and has suggested that, in theory, the concept can deliver 99% wave power termination capabilities. ♦ George Marsh: Engineering roles in high-vacuum physics, electronics, flight testing and radar led George Marsh, via technology PR, to technology journalism.

This article was published in the January/February 2014 issue of Renewable Energy Focus magazine.

The digital edition of Renewable Energy Focus is free of charge to readers meeting our qualification criteria. To apply to receive your copy of the magazine please complete this short registration form.