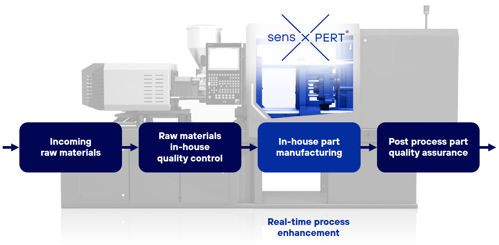

Figure 1. sensXPERT provides a real-time process window to ensure quality on every single part. (Graphic courtesy sensXPERT.)

In order to achieve consistent part quality – regardless of whether a part is being molded in Germany, Mexico, or China, on a hot humid summer evening or a cold dry winter day – technicians everywhere are searching for tools that bring greater stability and more reliable control over their molding processes. Given all the different polymer systems and processes currently used in this industry, most of the available tools used to help molders gain more consistent control of their processes are very specialized. They work with only a few polymer families or in a single molding process.

Founded in 2021 and based in Selb, Germany, sensXPERT is a technology brand business of NETZSCH Process Intelligence GmbH, a NETZSCH Group corporate venture. sensXPERT provides data-driven manufacturing solutions that help customers in the plastics processing industry enhance their productivity in real-time.

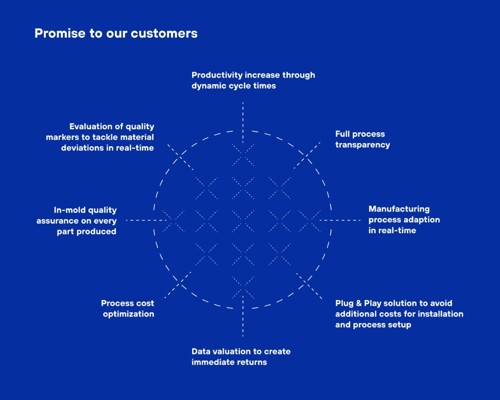

At sensXPERT, we set out to create a more flexible tool that would be process and material agnostic. We also wanted to develop a tool that could tell process engineers not only if the last part they molded was in spec, but also if the part that is currently in the tool is going to be acceptable. To do this, we integrated our expertise in materials characterization and a new type of sensor with machine learning algorithms that, combined, provide a reliable description of how a process is proceeding moment-by-moment and how that will likely impact the ultimate performance of that part once it is ejected and used in the end use environment. Eventually, we hope to connect our system with press controls to automatically detect when a process is starting to drift and to bring it back into acceptable parameters automatically.

Meeting tomorrow’s needs today

Today’s manufacturing environment relies heavily on in-house materials characterization and modeling, process simulation, workforce experience, and material-supplier datasheets with limited information. It also necessitates high investments of material, energy, and machine/technician time during process setup as well as post-process quality assurance (QA) checks. This makes processors dependent on each supplier’s own QA processes and reporting transparency. In most cases, these engineers are unaware of all the factors influencing material behavior during the production process. And there is often a missing interface between manufacturing solutions and process efficiencies that can impact the bottom line.

To meet today’s market demands for end-to-end, integrated and tailored solutions, processors need consistent process stability and component quality. They need real-time material and process transparency, plus real-time quality assurance for each part produced based on the measurement of critical data, such as degree of cure, glass-transition temperature, gel point, flow behavior, and degree of crystallinity.

The sensXPERT solution helps molders access untapped potential in their processes and quantifiably increase productivity by using real-time materials characterization and data analytics, combining machine, cavity, and material data in an interrelated and symbiotic system. Material and process characterization is tracked via in-mold sensors. Process data are turned into quantifiable part quality measures using machine learning algorithms geared toward future analytics and forecasts. Cloud data storage ensures access and comparisons to all manufacturing data wherever a technician is—across the facility, across town, or across the continent.

Controlling the process

sensXPERT is part of NETSZCH, a global technology leader with more than 50 years’ experience developing materials characterization and testing equipment and sensor technology. With over 4,000 employees deployed in 36 countries, we have a broad understanding and deep expertise in scientifically characterizing and quantifying material behavior.

Processing engineers need to know immediately if a factor inside the tool or outside the press is likely to cause process settings to make a change , that could affect, even subtly, the quality and performance of the part being processed. There is a lot of hidden potential that part manufacturers cannot access until they gain more consistent control of their processes, such as the ability to reduce cycle times, energy usage, scrap, machine downtime, and cost of goods and services (COGS). Our technology has been designed to provide processors with faster and more efficient responses to the interaction between process parameters and material behavior. If an error occurs, our system quickly helps a technician troubleshoot the issue, minimizing downtime and reducing the number of bad parts that are produced before the problem is discovered. In general, we have found that our system reduces scrap by up to 18%, energy usage by up to 23%, cycle time by up to 30%, and machine downtime (due to maintenance, software installation, and troubleshooting errors) by 15 days per year.

Materials characterization meets machine learning

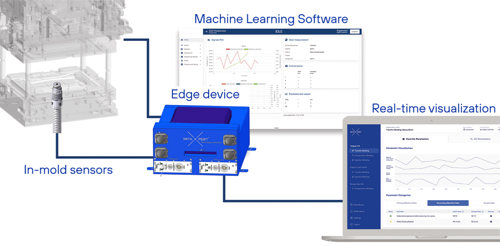

Our system begins with several pieces of hardware: two specialized dielectric sensors installed in a mold (one placed beside a gate at the start of flow and one placed at the end of flow), and an ’edge device’, which is a machine that sits outside the press and collects data measured by the sensors inside the tool as well as process parameters from the press itself. The edge device uploads that information to the Cloud via secure servers maintained by Amazon Web Services.

The software involved combines mathematical and physical/chemical models of polymer behavior plus machine learning algorithms that constantly scan for patterns in Big Data in order to translate raw sensor data into predictive quality criteria. There also is a web app that enables our Cloud-based system to communicate with the technician monitoring a given press without a need for a laptop and keyboard. It is the algorithms’ ability to parse huge collections of data flowing in from molds in real manufacturing environments all over the world that helps the system get smarter over time. If the algorithms flag a set of data as different, our machine learning software alerts the local technician monitoring that press that something is changing. It is then up to that operator to decide whether or not to act. In the meantime, the machine learning software remembers and instructs not only the local system but also any other press connected to the system that is running the same kind of process and material. In this way, the system is constantly being retrained as more data are gathered and more patterns are detected to continuously enhance the process performance.

The combination of process parameters, sensor data, and data science have brought us to the point where we have built extensive databases that enable us to accurately predict part quality based on complex and interrelated factors occurring inside and outside the mold during each molding cycle. This, in turn, enables a process engineer to get a clear picture of how the process is proceeding in real time and whether it is likely to produce good parts upon demolding. The fact that our system keeps getting smarter as more data flow into our databases sets the sensXPERT system apart from anything else on the market today.

About the author

Dr Alexander Chaloupka is sensXPERT managing director and CTO.