NOVA is a two-year renewable energy feasibility project, supported by the UK Energy Technologies Institute (ETI) and the Engineering & Science Research Council (EPSRC), with financial support from the European Regional Development Fund (ERDF). The project aims to investigate the affordability and feasibility of manufacturing a VAWTS of this design and scale.

The 50 kW prototype was manufactured at Cranfield University’s Composites Centre, with support in its design and manufacture provided by key materials suppliers. These included Scott Bader, whose Crystic® Crestomer® 1152PA urethane acrylate structural adhesive has been specified for bonding the various carbon fibre and glass fibre epoxy composite parts which make up the two 10 m by 1.9 m rotor sails.

To be a viable, the planned massive scale up in offshore wind turbine manufacture will require the rotor blades to sustain at least 20 years’ service without maintenance. As such, the structural design and selection of suitable high quality materials with these long term performance capabilities is a critical factor for this project. By first developing a 50 kW prototype scaled down demonstrator with embedded structural strain and air pressure monitoring, the NOVA project team will be able to gain an understanding of the engineering performance and aerodynamic behaviour of the design in use and extensively test the composite materials selected in offshore operational conditions.

The fabrication stage has already helped the team to address on a much smaller scale, any processing challenges to cost effectively manufacture and assemble the composite components. These insights can then be applied to the full sized version to help ensure its affordability and commercial viability.

The overall turbine assembly has been designed and constructed to have the best structural reliability long term in order to meet the key criteria of being ‘maintenance free’ during its expected 20 years service life. The two prototype rotor sails each have dimensions of 10 m long by 1.9 m wide, with a maximum depth of 180 mm at the mid section.

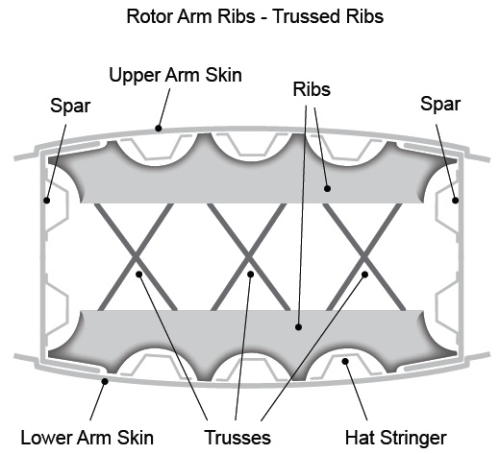

The structural approach used for the rotor sails is similar to a large commercial aircraft wing. The sail has a central box section, designed with tapering thickness skins, two C spars with ribs and ‘omega’ shaped hat stringers to provide resistance to buckling (Figure 1). The sail central box components were manufactured from multiaxial carbon fibre fabrics and epoxy resin using a vacuum infusion moulding process. To the central box is added glass fibre reinforced leading and trailing edge components.

| Bearing in mind that the scaled up 10 MW wind turbine sails would be 80 m long, finding ways to reduce weight in the overall sail design was critical. |

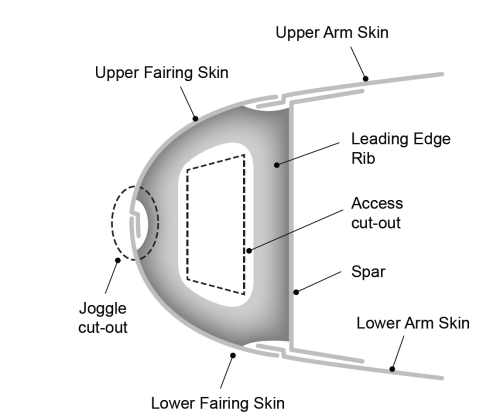

Bearing in mind that the scaled up 10 MW wind turbine sails would be 80 m long, finding ways to reduce weight in the overall sail design was critical. For the prototype, the rotor sail weight was significantly reduced by using a structural adhesive, which had the added benefit of providing lower overall manufacturing costs compared to a jointed sectional and mechanical assembly design. The carbon fibre/epoxy ribs, spars and skins of the box design were bonded together with Scott Bader Crystic Crestomer 1152PA adhesive. The leading and trailing edge components, separately fabricated from glass fibre/epoxy composite, were then bonded onto the central box of the sail. All the bond joints used a simple joggle design and shim plates to allow for rapid assembly with minimum fixtures and aerodynamically smooth joints (Figure 2).

As the adhesive was such a critical factor in both the manufacturing and long term offshore performance of the two lightweight rotor sails, Cranfield University Composites Centre carried out its own detailed study to evaluate a range of possible adhesives for this very demanding application.

“The design and scale of the sail rotor structure means that there are large bond surface areas and wide bond lines,” explains Andrew Mills, Nova project leader at Cranfield University Composites Centre. “The fully cured structural adhesive must, therefore, have long term performance properties which meet a number of key requirements. These include gap filling and providing outstanding peel resistance, while at the same time being strong and very tough, with exceptional flexural strength properties.”

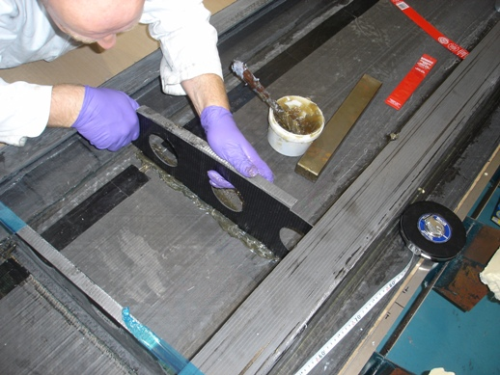

The Cranfield team carried out adhesive performance comparative testing on a range of bond-line thicknesses from 30 mm down to 2 mm. The test results obtained showed that the best performing adhesive for bonding both carbon fibre and glass fibre epoxy laminate substrates was Crystic Crestomer 1152PA. These findings are supported by to the quality and long term performance of Crestomer adhesives, which have already been proven for over 30 years in many demanding composite marine applications, such as deck and hull stringer and bulkhead bonding, endorsed by both Lloyds and RINA for composite bonding in a variety of marine applications.

For the 10 m sail prototype, each component and mould tool was designed with joggled part fit, scored fitting positions and 1 mm adhesive shims. This provided accurate final sail dimensions without the use of complex assembly jigs. As part of the assembly process to ensure joint accuracy, after positioning without adhesive, each part was drilled and the holes used to either pin or rivet each part together after adhesive application. All of the adhesive joints were post cured in a portable taped foam board oven for 24 hours at 50°C and joint gaps were subsequently filled with a body filler and abraded smooth using a circular sander to eliminate evidence of the component joints. ♦

This article was published in the January/February 2012 issue of Reinforced Plastics magazine.

The digital edition of Reinforced Plastics is distributed free of charge to readers who meet our qualifying criteria. You can apply to receive your free copy by completing the registration form.