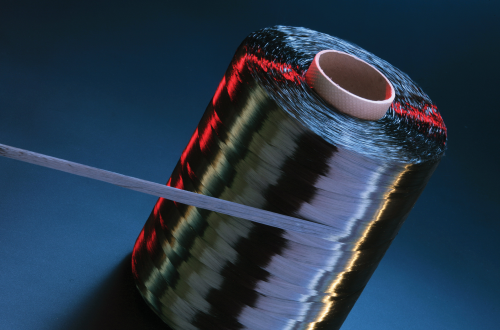

Several of the largest carbon fibre producers reported sharp drops in sales in 2009 but remain optimistic for an upturn in 2010 and beyond.

SGL Group of Germany reported in a November financial report that the market for carbon fibres is “currently facing temporary overcapacity due to the numerous delays in new aircraft projects, delayed investments in wind energy, as well as declining demand in sports and consumer applications."

"That has produced an increasingly competitive environment, which is currently having a negative impact on prices and volumes,” the company stated.

Hexcel, a leading US carbon fibre producer and weaver of reinforcement fabrics, reported its largest year over year sales decline in years in a third quarter statement. “We expect the short term to remain challenging due to inventory management by our customers, weakness in regional and business aircraft markets, and credit market impacts on our industrial customers, but the fundamentals for longer-term composites growth remain the same," Hexcel noted.

Japan-based Toray Group, which also reported a significant drop in sales in recent months, relates that demand has been stagnant in the carbon fibre composite materials segment. Reflecting the global economic downturn, shipments in aircraft and space, sports, and general industry applications declined, the report said. Toray is actively pursuing development of new products and sales expansion with a focus on energy and automotive applications. A new production facility for carbon fibre prepreg has begun operation to develop a supply structure to meet anticipated future growth in demand, Toray relates.

USA-based Zoltek, reporting year-end results, indicated that 2009 had been an extremely disappointing year in terms of sales, but that the company remains “very optimistic that the wind energy business will return to much higher growth rates and fulfill long-term expectations of becoming a much bigger part of the energy mix."

Zoltek has entered into a technology and marketing agreement with Global Blade Technology of the Netherlands to design and manufacture wind turbine blades using Zoltek fibres. "Additionally, several other applications, namely automotive, deep sea drilling and infrastructure, are in advanced stages of development and testing and offer enormous potential,” Zoltek related in a statement.

“We entered the year riding the crest of a wave of four consecutive years of rapidly increasing sales and improving operating results,” noted Zsolt Rumy, Zoltek’s Chairman and CEO. “We believe that the current downturn in carbon fibre markets represents only a temporary departure from a long-term trend line of rapid growth,” he added.

Rumy called BMW’s recent announcement that it intends to proceed into series production of a new car using carbon fibres for the car’s structural framework “a great breakthrough for the concept that we introduced to BMW over a decade ago.” Indicating disappointment that BMW chose to partner with SGL, he related that Zoltek is in discussions with other automakers which may also be interested in developing carbon fibre-based cars.

This article is an extract from a feature published in the January/February 2010 issue of Reinforced Plastics magazine. You may download the complete feature here at no cost.