Retrac Group, a composites and metal manufacturer, has developed a new range of sustainable bio-composites.

The materials are five sustainable or recycled composite materials featuring recycled carbon fiber and natural fiber products. Retrac says that it also uses bio-content resin systems and an energy-efficient production process featuring bespoke compression molding techniques.

‘The world is on the cusp of a light-weighting revolution, and Retrac Group is positioning itself at the forefront of knowledge and techniques to maximise successful applications of natural fibres and recycled composites,’ said CEO, Dan Walmsley.

The company has reportedly partnered with flax natural fiber specialist Bcomp and UK-based prepreg manufacturer Composites Evolution, which supplies prepreg with natural fiber reinforcements.

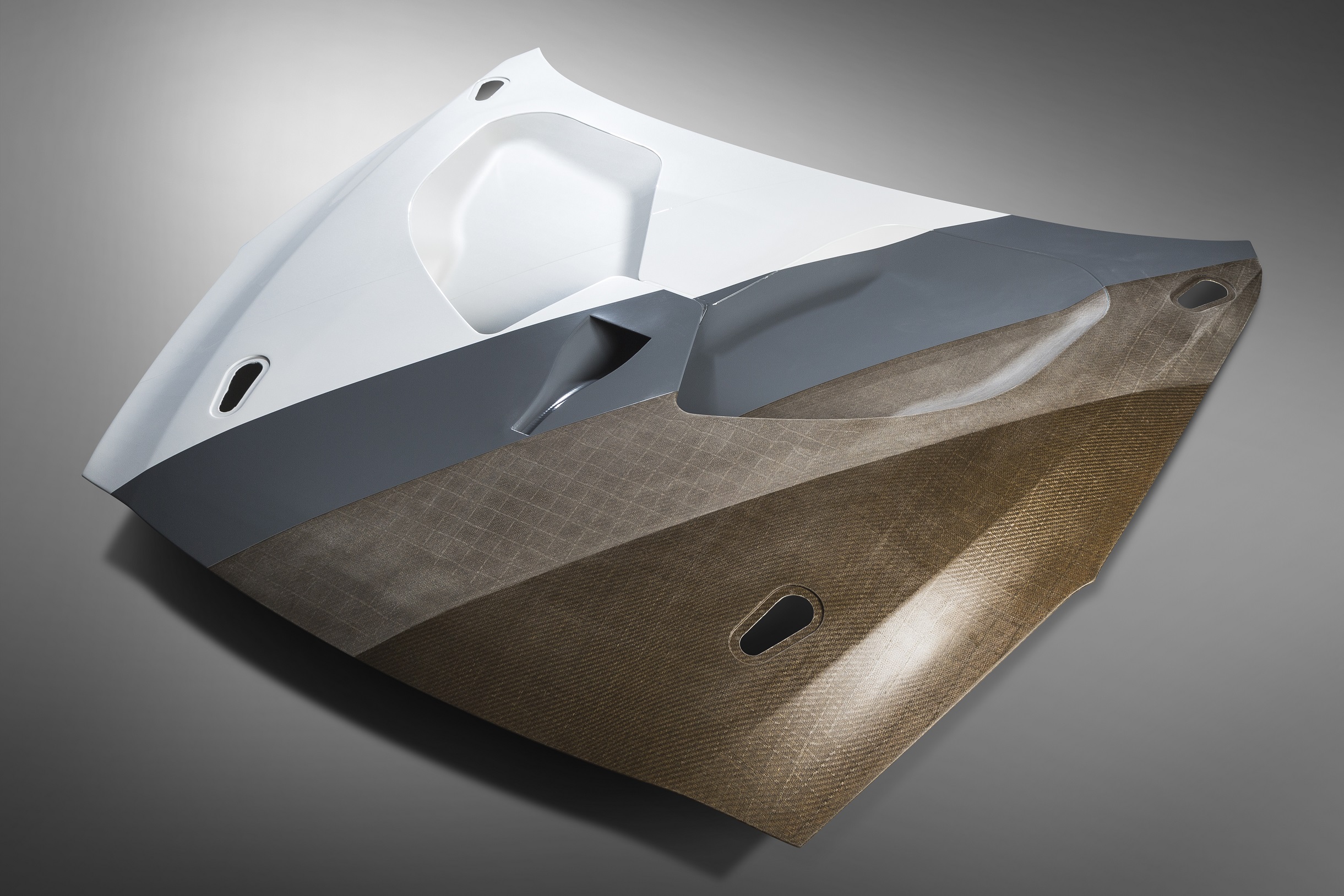

Using the materials, Retrac has produced a demonstrator bonnet panel for a supercar which it says it will be showing at the year’s Advanced Engineering Show, taking place in Birmingham, UK, from 3-4 November 2021.

Other materials include a flax material and a resin system using sustainably sourced ingredients, a recycled carbon fiber material, and two thermoplastic materials from woven carbon and woven glass respectively.

Retrac says that it has also signed up to the UK Government’s SME Climate Commitment to halve its greenhouse gas emissions by 2030 and achieve net zero emissions by 2040.

This story uses material from Retrac, with editorial changes made by Materials Today.