Solvay says that its Torlon reinforced plastic has been used to form several key components in a dual concentric slave cylinder (dCSC) developed by FTE Automotive.

This is reportedly the first time Solvay’s materials have been used for this type of application, the company says.

FTE Automotive’s dCSC forms the part of the new SGM X44F Dual Clutch Transmission from SAIC General Motors Co Ltd. The transmission was successfully launched on the 2015 Chevrolet Cruze platform for vehicles produced and sold in China.

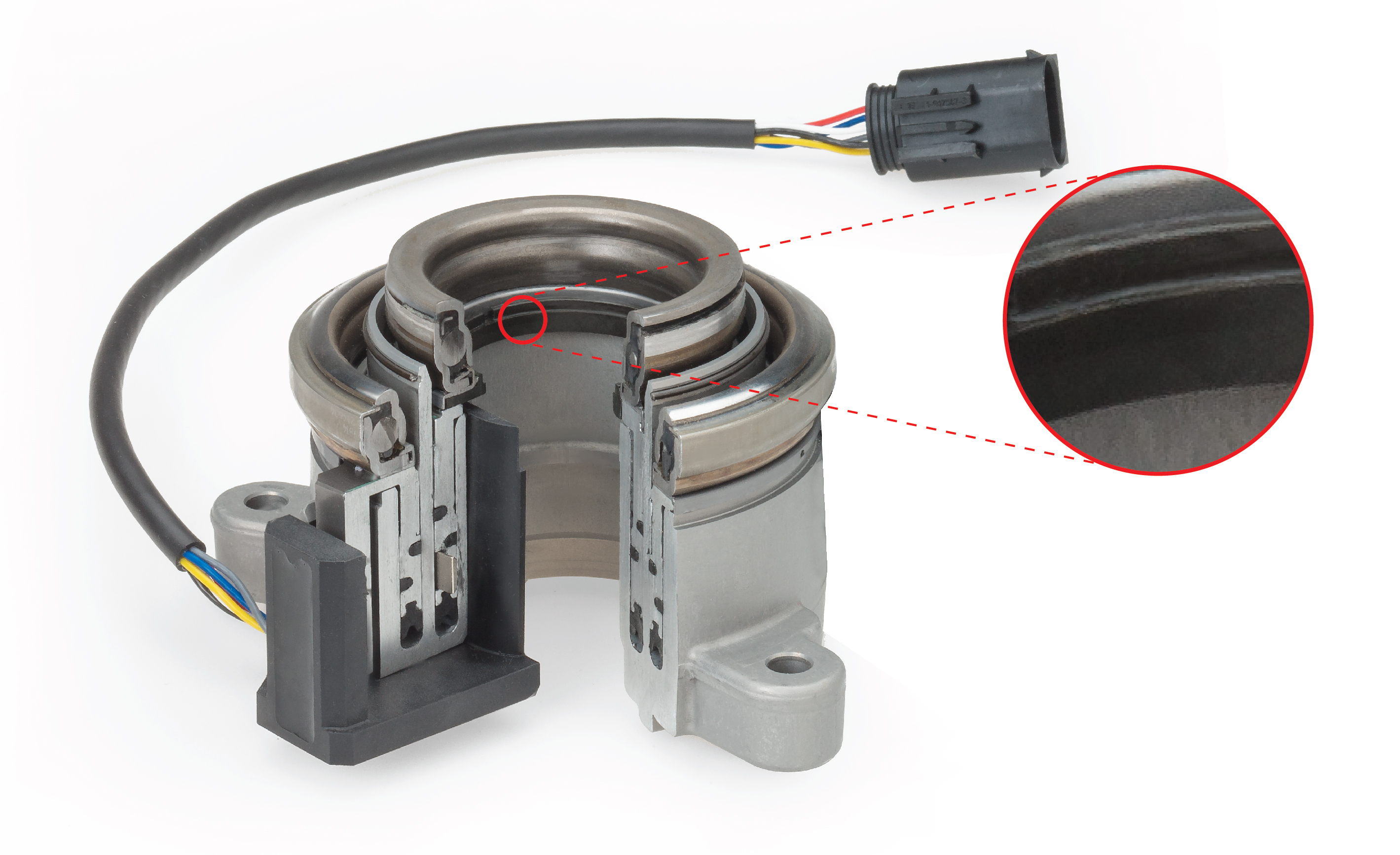

The critical core of an automotive clutch system, concentric slave cylinders are positioned directly around the drive shaft and on the clutch. They are consequently subject to extreme loads each time a car shifts gear. FTE Automotive offers various CSC designs for light and heavy commercial vehicles that, depending on the application, are usually fabricated from aluminum or engineering polymers.

FTE Automotive chose Torlon 7130 PAI reinforced with 30% carbon fiber loading to make an innovative locking device to maintains radial positioning within the dCSC throughout the transmission's life cycle requirements, avoiding friction and exhibiting low wear. The improved lubricity and fatigue resistance of the grade enables the locking device to withstand millions of loading cycles from the torsional excitation of the clutch.

This story is reprinted from material from Solvay,with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.