North Thin Ply Technology (NTPT) and 4a manufacturing, a specialist in thin foams and micro sandwich materials for acoustic and lightweighting applications, have formed a partnership to develop new micro music speakers.

4a manufacturing has been producing tight tolerance hard foam sheets down to a thickness of 0.2 mm and combining them with metal skins to form ultra-thin sandwich materials. Recently, the company looked into increasing the stiffness of the aluminium sandwich skins in materials for the micro speakers used in mobile devices such as lap tops, mobile phones, and tablet computers. One of the main challenges for prepreg materials in these thin sandwich materials is maintaining uniformity of the carbon fiber layers, which becomes an even more critical property as ply weights decrease, according to NTPT.

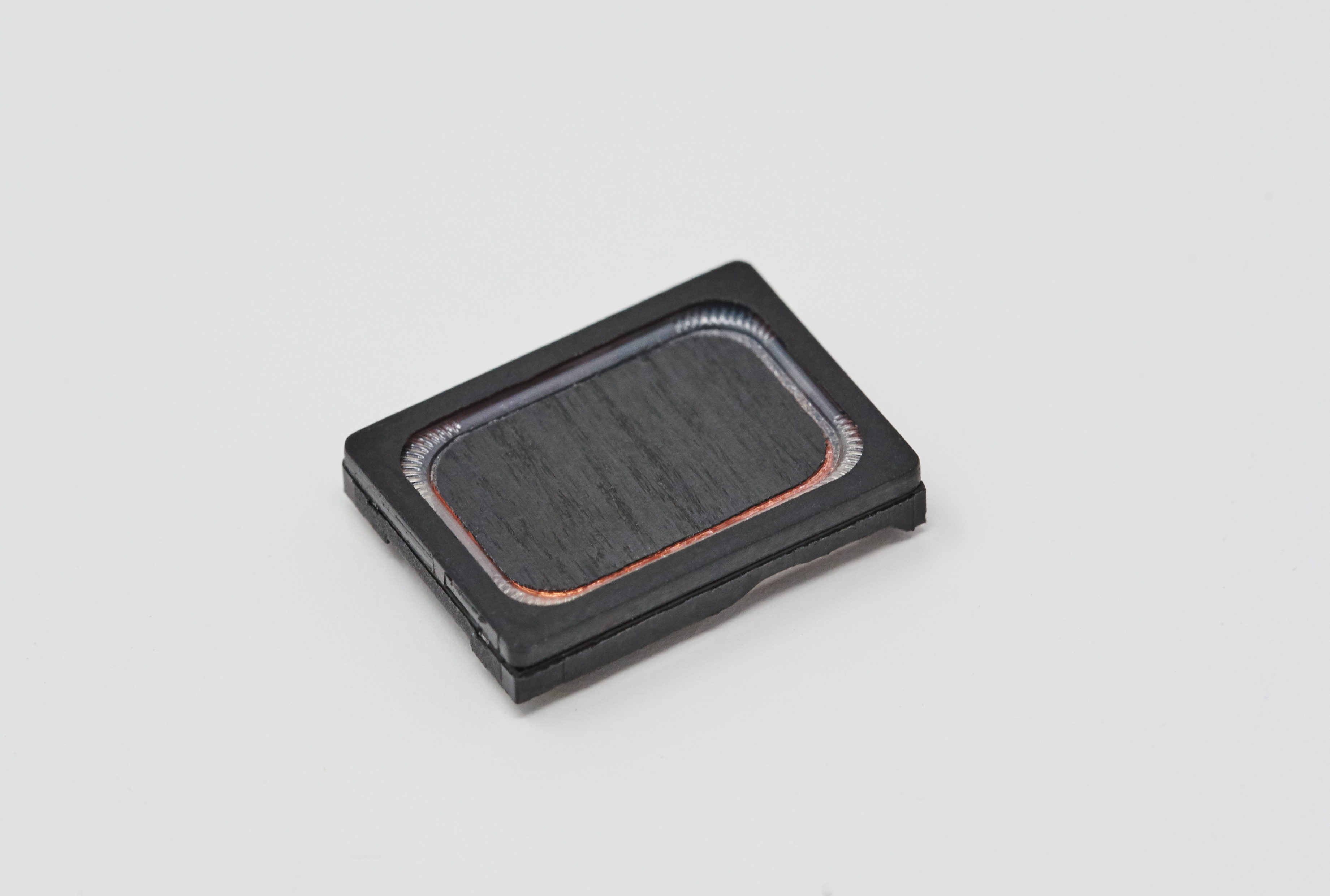

The companies used NTPT prepreg tapes, which can have areal weights as low as 15 gsm with high modulus fibers (>300GPa), to develop a new micro sandwich using a 20 gsm (0.02 mm thickness) prepreg and a total thickness lower than 0.2 mm.

The two companies now offer flat panel carbon fiber micro sandwich laminates (direct from 4a manufacturing) or a materials package of NTPT thin ply prepregs and cores for those wishing to mold their own thin 3D sandwich components.

This story is reprinted from material from NTPT, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.