Technical Fibre Products (TFP) reports that its aramid nonwovens can help protect against abrasion or wear nonwovens in composite surfacing applications.

According to a recent study, the company’s lightweight aramid veils show effectiveness in protecting the underlying structural elements of a composite, the company said. This makes them suitable for applications such as high speed composite rollers, automotive friction substrates or sporting goods where the composite experiences a constant friction.

The study examined the effectiveness of using a surfacing veil to increase wear resistance by comparing composite panels fabricated both with and without TFP’s aramid veils. The panels (based on epoxy resin and woven carbon) were tested using a pin-on-disk tribometer to measure friction and wear as a function of time. According to TFP, the data generated demonstrated that the measured coefficient of friction was significantly lower when an aramid surfacing veil was used, taking at least five times as long to reach the level measured in the control.

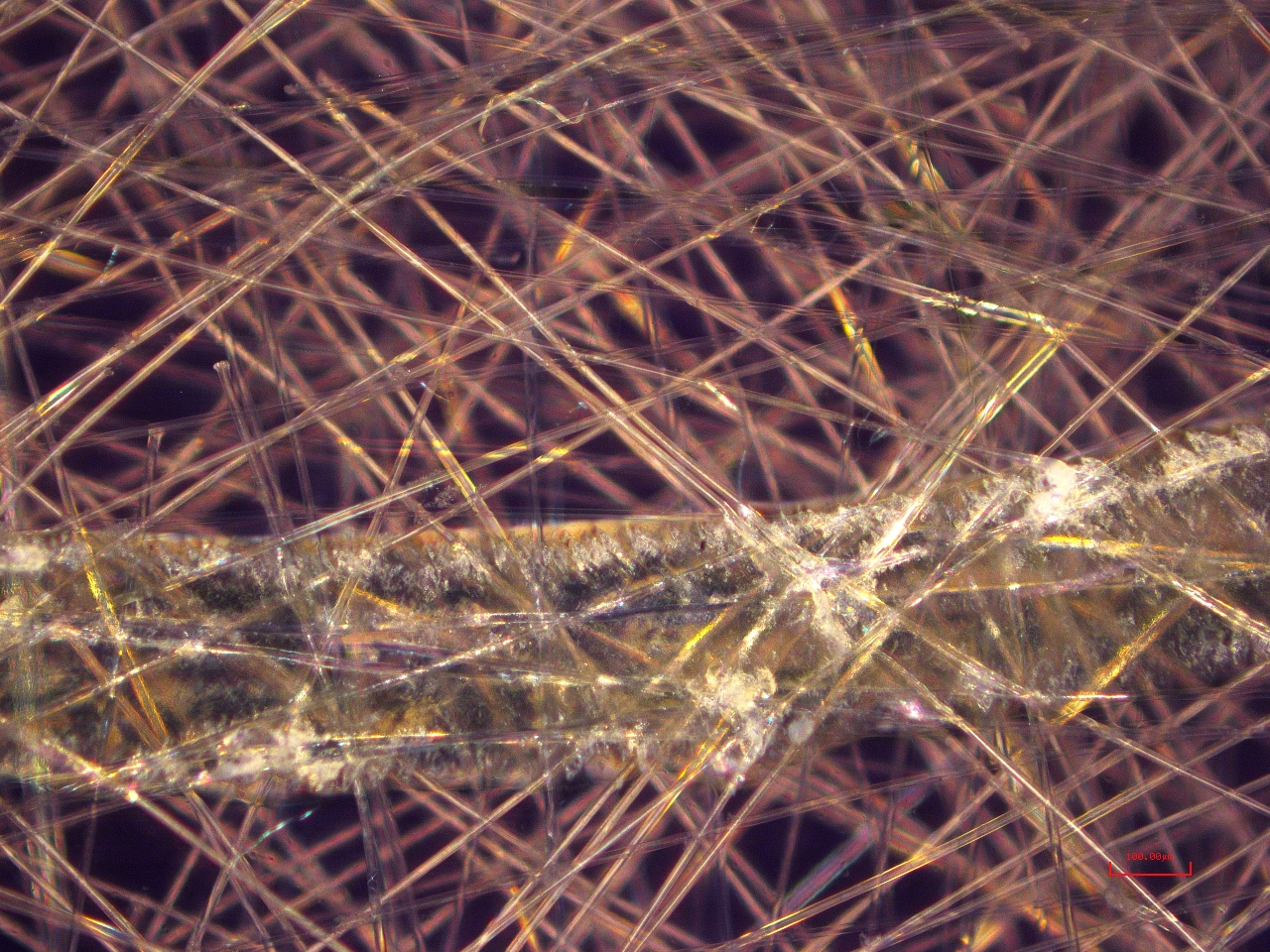

‘Essentially, this indicates that the level of friction experienced by the composite surface is significantly lower and less material is worn away as a result,’ a press release said. ‘This finding is reinforced by microscope imaging of the samples showing just damage (and no breakage) to the surface fibers and no damage to or exposure of the woven reinforcement in the composite panels containing aramid surface veil.’

TFP notes that there was evidence of significant fibre breakage and damage to the underlying carbon weave in the control panel.

More information on the study (including data and images) can be found here.

This story uses material from TFP, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.