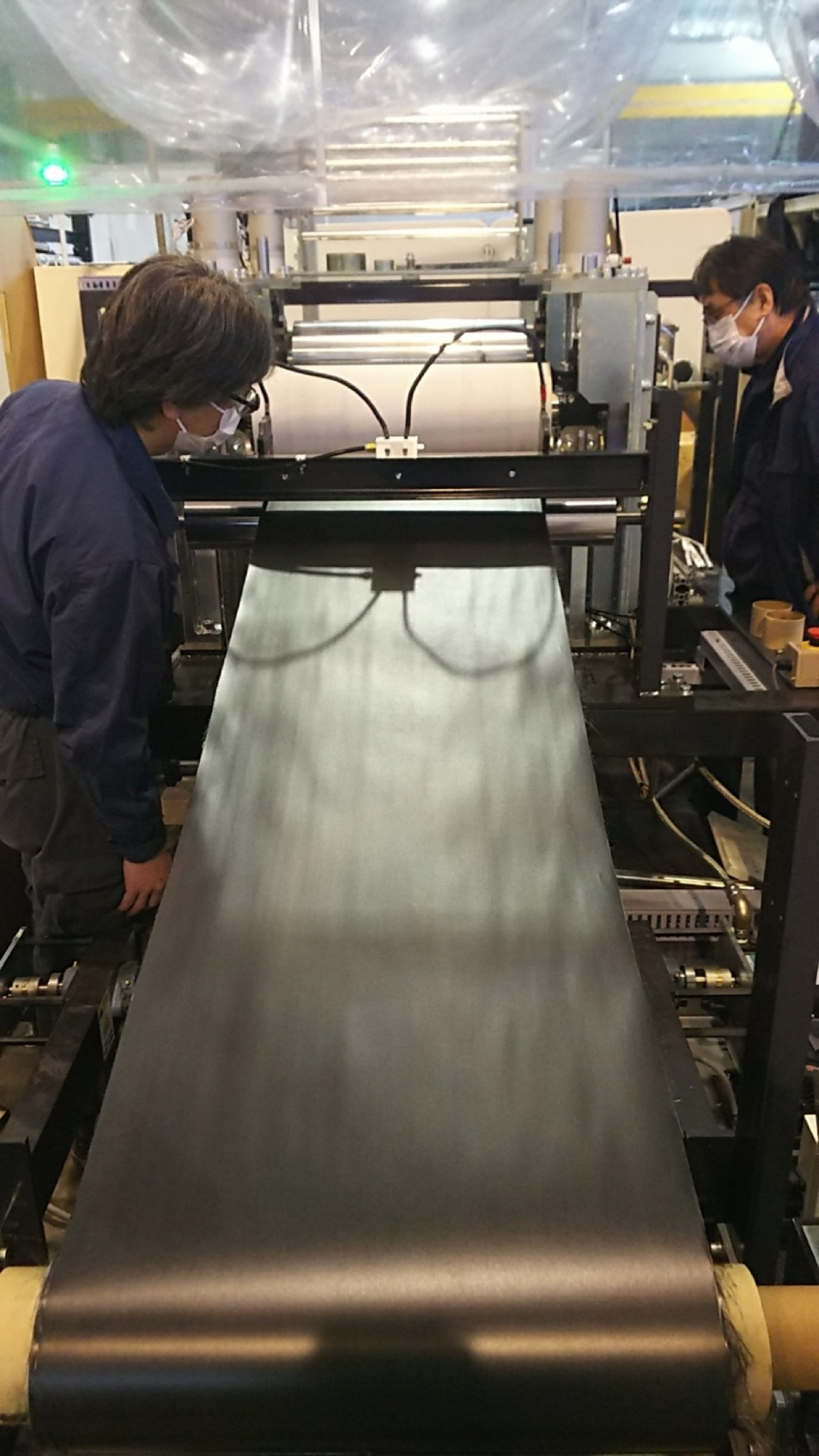

MaruHachi Group, a Japanese composite manufacturer, has installed a new high-temperature unidirectional tape line to make thermoplastic tapes and laminates.

The company reportedly plans to produce up to 40 tons/year, focusing on uni-directional (UD) tapes and multi-layer sheet laminates based on carbon, aramid, glass or natural fibers embedded in polyphenylene sulfide (PPS), polyether ether ketone (PEEK) or other higher temperature polymers.

The lines have a width of 500 mm and a specific weight from 60 to 350 g/m2 depending on the chosen material, and can operate under temperatures up to 420°C.

Plans are to develop materials for the aerospace and automotive industries, MaruHachi said.

‘For many years, we have already been cooperating with domestic and international partners on high-demand applications and therefore, MaruHachi decided now to invest over €1 million in this new line in phase 1, including a funding participation from the Japanese government NEDO,’ said Toshi Sugahara, CEO of MaruHachi. ‘New developments in phase 2 will be undertaken by end of 2021 on the downstream technologies like the automated preforming and consolidation. With our new products, we want to contribute to significant weight reductions of the final products, thus improve energy efficiency while offering a cost-efficient and high-quality solution.’

This story uses material from MaruHachi, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.