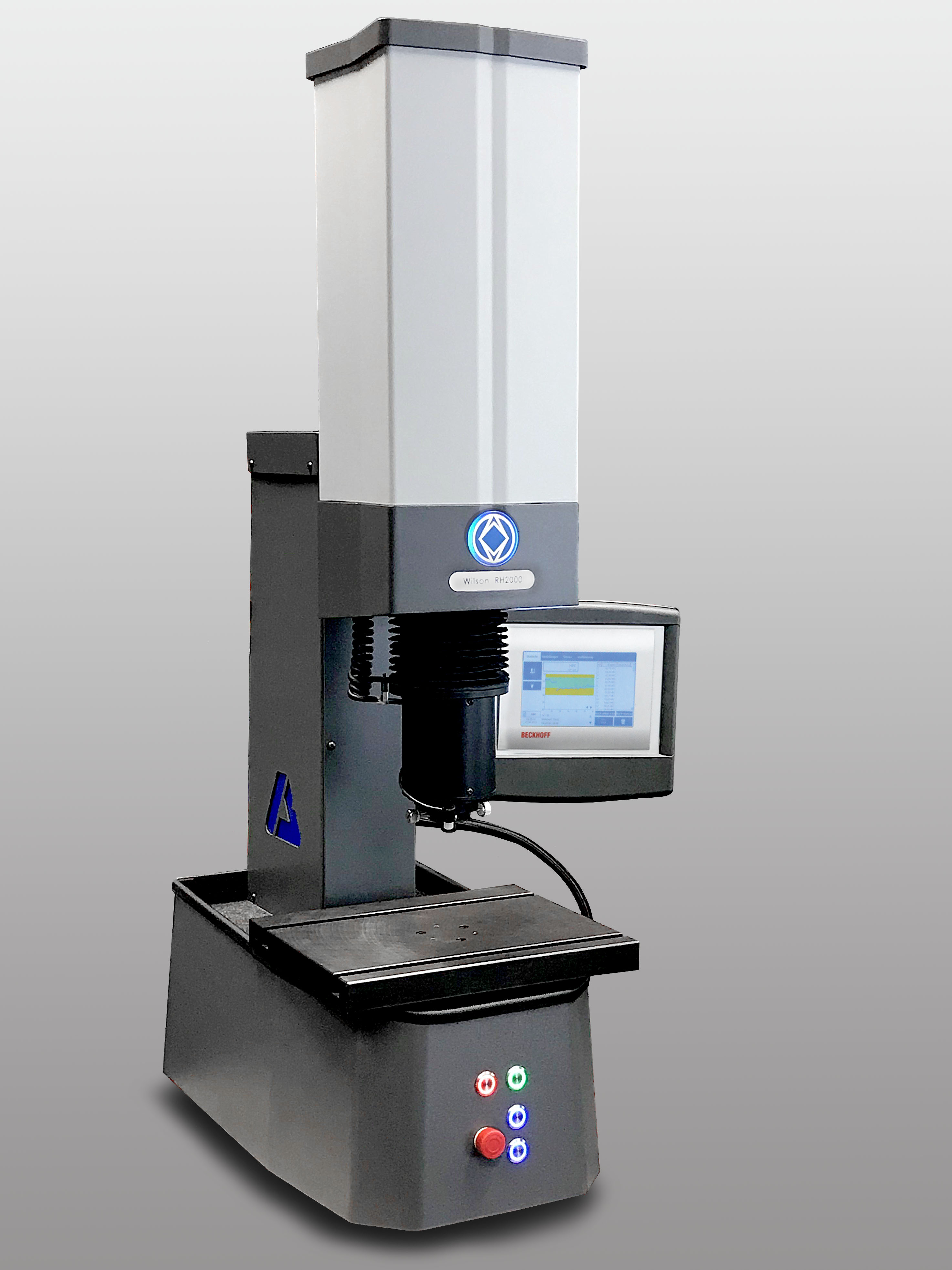

Buehler ITW Test & Measurement has developed a new hardness tester which can test a range of different parts and components in both high-volume production and R&D.

The Wilson RH2150, which is based on the company’s RB2000 tester, features a new user interface and improved statistical calculations, results graphing and test programmability. Results can be exported as csv and/or txt file on a memory device via an integrated USB interface, while configurable DiaMet test software is also available, according to the comapny.

The Wilson RH2150 series is available in a regular version appropriate for the regular Rockwell scale, and a twin version which also allows measuring in the superficial Rockwell scale. As well as this, both can be used for Brinell depth testing with up to 187.5 kgf and for ball indentation testing. The maximum specimen heights are 10″ (254 mm) with size 1 and 14″ (356 mm) with size 2 of the tester. The maximum specimen weight is 50 kg (centered on anvil).

‘The trend towards ever tighter manufacturing tolerances and more advanced heat treatment methods in the automotive and aerospace industries require hardness testing systems to be durable while maintaining precise control during critical test data generation,’ said Buehler hardness product manager Matthias Pascher. ‘They must be easy to use, yet flexible enough to meet the increasing demands in the industries.’

This story uses material from Buehler, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.