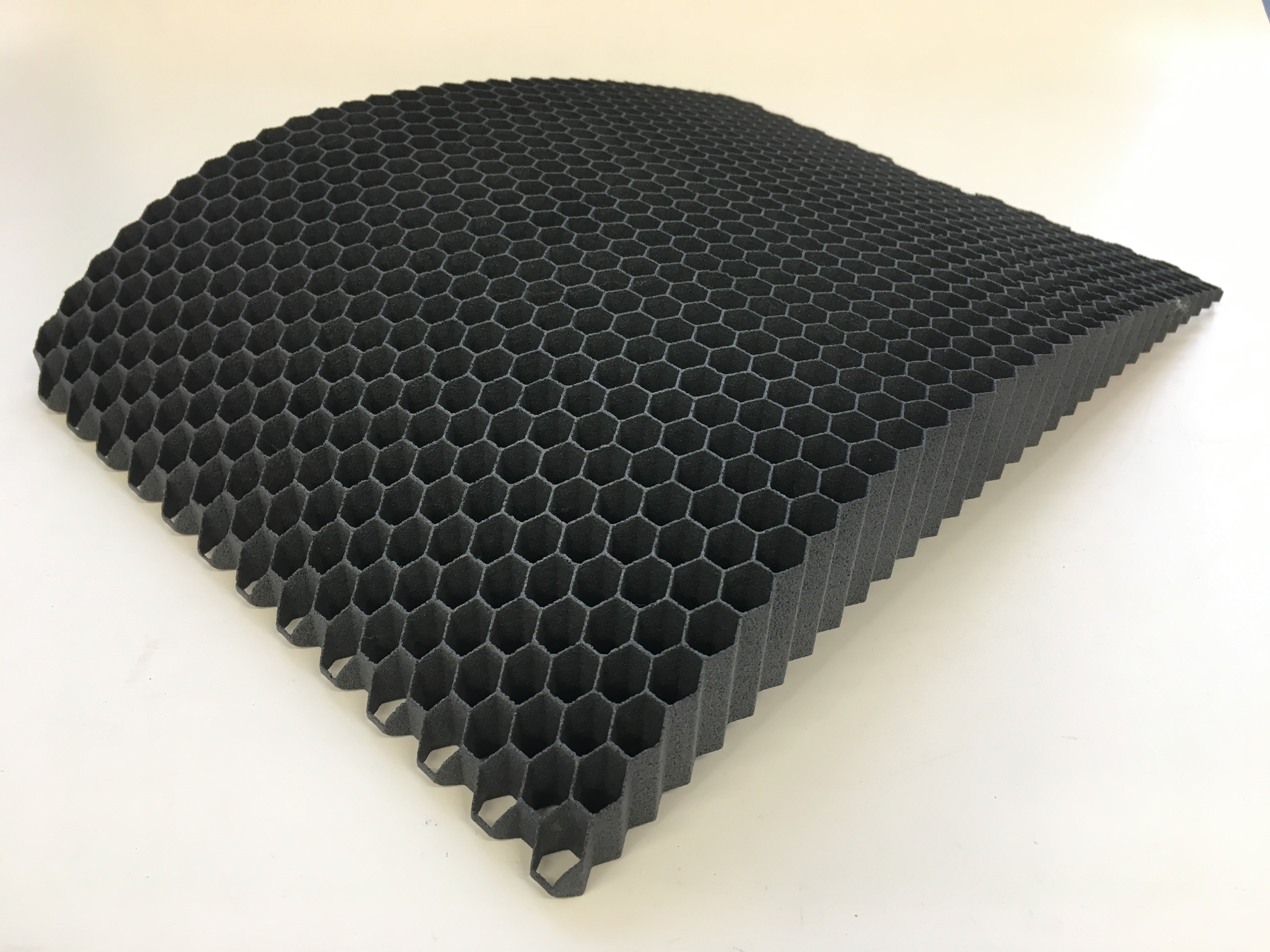

Hexcel has launched a new electrically conductive, polyetherketoneketone (PEKK)-based thermoplastic carbon fiber composite suitable for additive manufacturing (AM).

HexPEKK EM is designed to meet the static electricity management, electromagnetic shielding, and radiation absorption requirements of aircraft applications and is suitable for commercial aerospace, defense, and military applications. According to the company, the composite components do not require secondary processing steps, such as the application of conductive coating for the management of electromagnetic interference or radiation absorption, and are thus flight-ready after 3D printing.

Hexcel says that HexPEKK EM is suitable for products such as exterior surfaces, leading edges, air inlets, electronic enclosures, and cockpit structures for commercial airplanes, military aircraft, helicopters, and UAV components.

‘The introduction of this advanced additive manufacturing material will enable the fabrication of extremely complex aerostructures with unparalleled structural and electrical functionality,’ said Lawrence Varholak, vice president of additive manufacturing at Hexcel. ‘It significantly reduces weight and cost while providing unlimited design flexibility.’

This story uses material from Hexcel, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.