Dura Composites says that it has supplied glass fiber composite for a UK fusion research company.

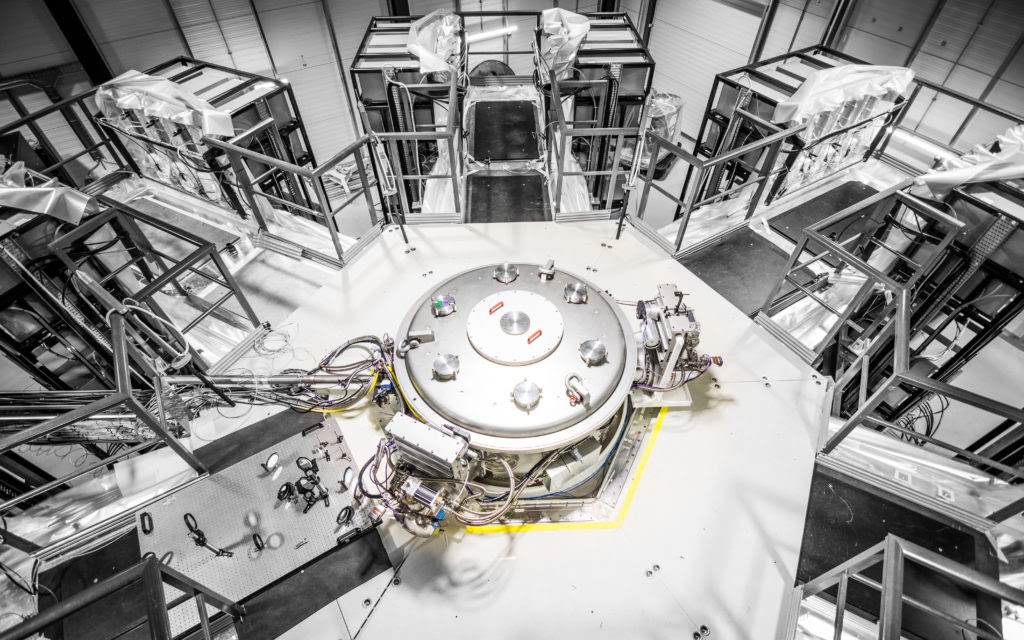

First Light Fusion, an Oxford-based research company, aims to develop fusion energy with a sustainable business model. The company plans to achieve inertial fusion by using shockwaves and has developed a pulsed power device called Machine 3.

According to Dura, Machine 3’s structure is made from non-conductive and non-corrosive glass reinforced polymer (GRP) and can discharge 200,000 volts and in excess of 14 million amperes within two microseconds, equivalent to around 500 simultaneous lightning strikes. This fires a projectile at a small target containing a tiny amount of fuel, collapsing a cavity and superheating the plasma in an attempt to achieve fusion.

By incorporating a non-conducting material in the structural elements of M3, we greatly reduced the design risk and allowed enhanced performance when dealing with extremely high voltages and an architecture of this type,’ said Paul Holligan, head of pulsed power at First Light Fusion.

This story uses material from Dura Composites, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.