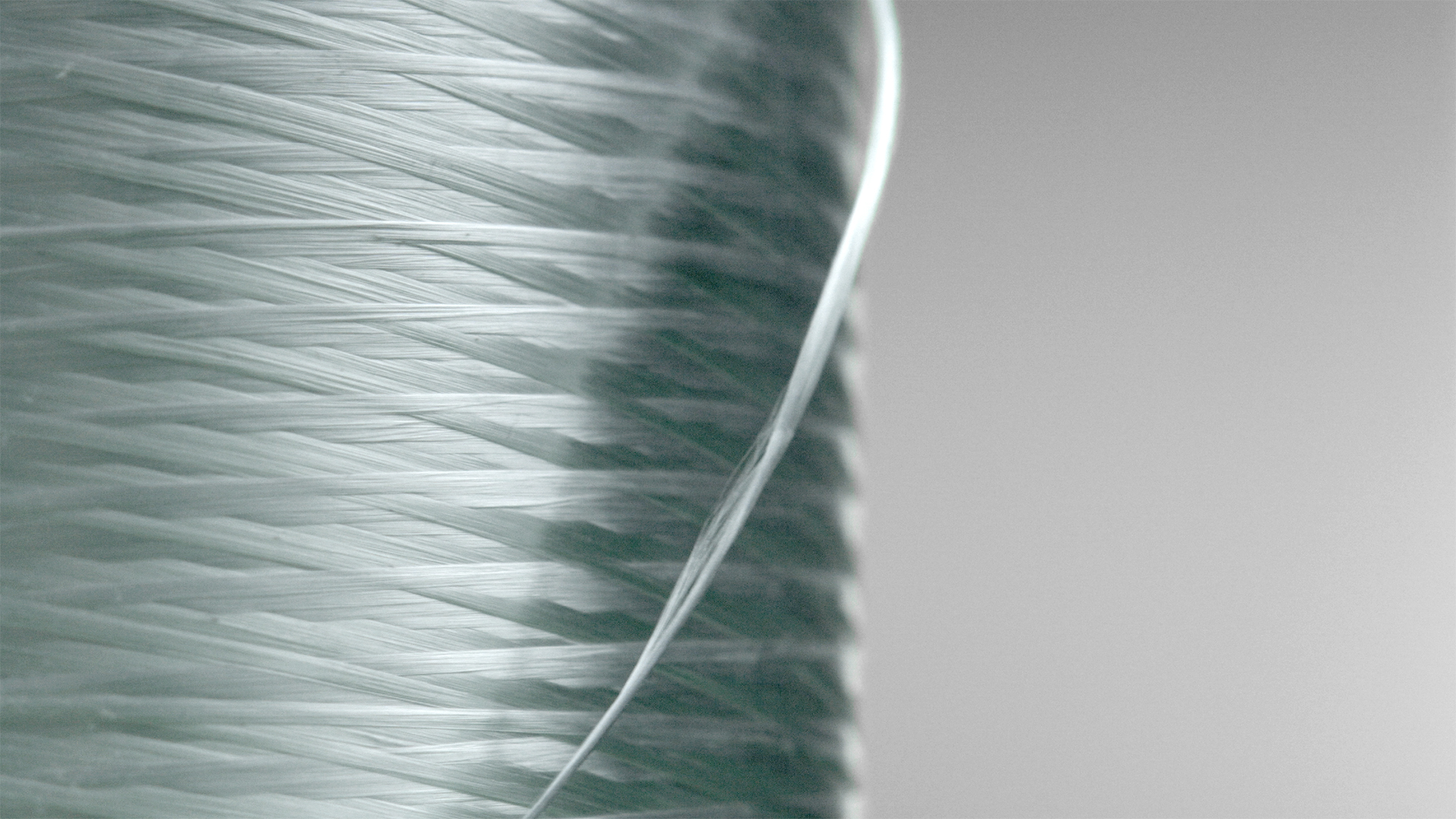

Chemical giants DSM and Sabic have partnered to create a version of DSM’s Dyneema fiber from ultra-high molecular weight polyethylene (UHMwPE) plastic waste.

DSM will produce the fiber from the plastic using Sabic’s certified circular ethylene and a mass balance approach, which allows the companies to track the amount of recycled content in the products. In two pilot projects, the fiber will be used to make a sailing rope and a fishing trawl net.

‘By working with partners from across the value chain, we are able to significantly reduce the environmental impact of the world’s strongest fiber – and we will continue to explore ways of reducing and eliminating waste across the entire product lifecycle,’ said Jan-Lodewijk Lindemulder, president of DSM protective materials.

This story uses material from DSM, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.