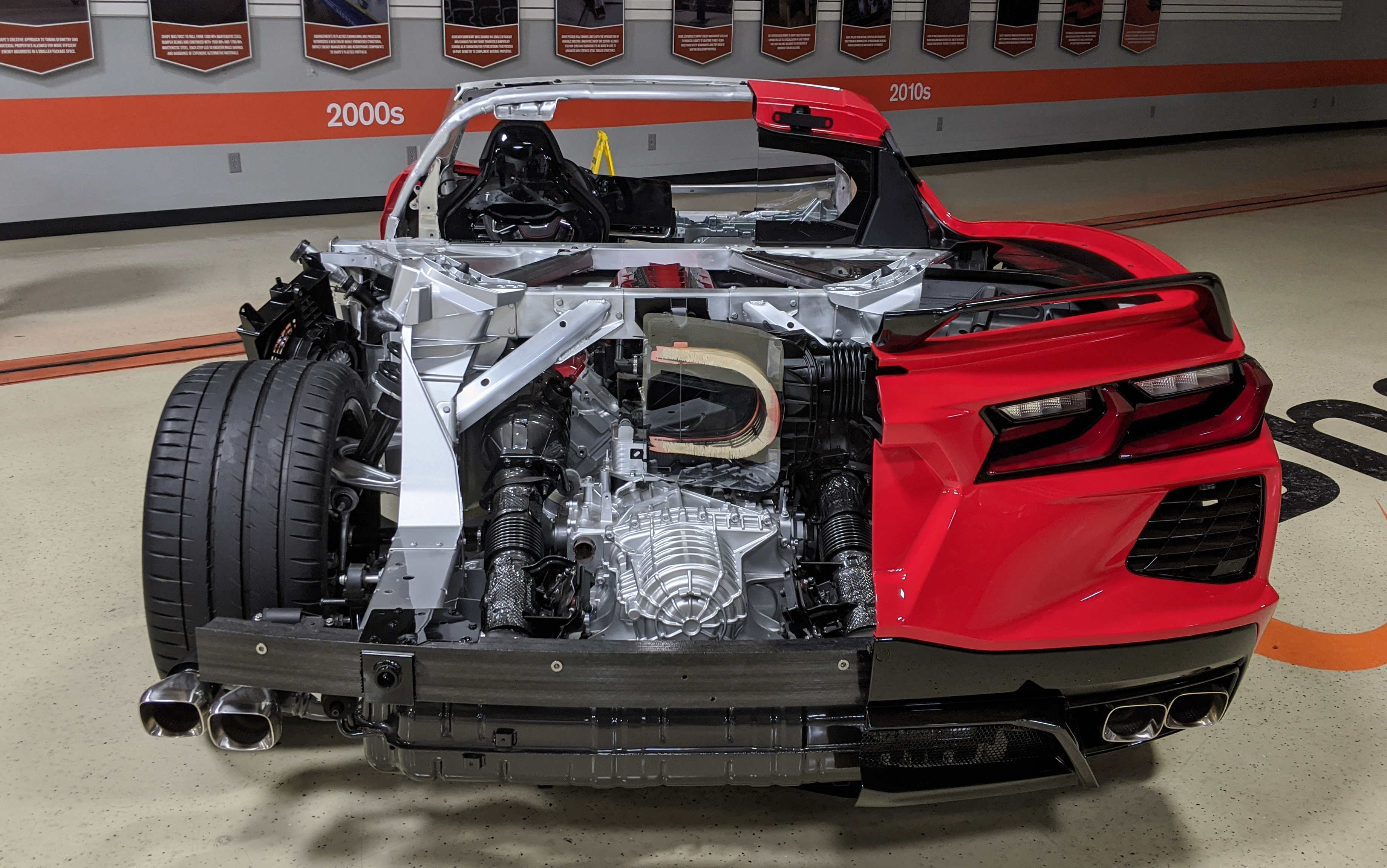

Pultrusion specialist Thomas Technik & Innovation (TTI) has collaborated with Tier 1 auto supplier Shape Corp to develop a curved carbon fiber rear bumper beam for the Chevrolet Corvette Stingray sportscar.

TTI says that its radius pultrusion technology is the only composites process that can produce the curved profiles in terms of improved safety, performance, production rate and cost requirements.

The beam is produced by running a set of reinforcements including carbon fibers from a creel as well as biaxial, triaxial and stitched unidirectional carbon fabrics, with glass surface tissues for stabilization and a better surface finish.

This story uses material from Thomas Technik, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.