BASF says that it has supplied its glass reinforced polyamide (PA) for the new 2021 Toyota Sienna.

According to the company, the vehicle won the Altair Enlighten Award for achievements in vehicle weight savings for the reduced mass of the third-row seat, which featured BASF material.

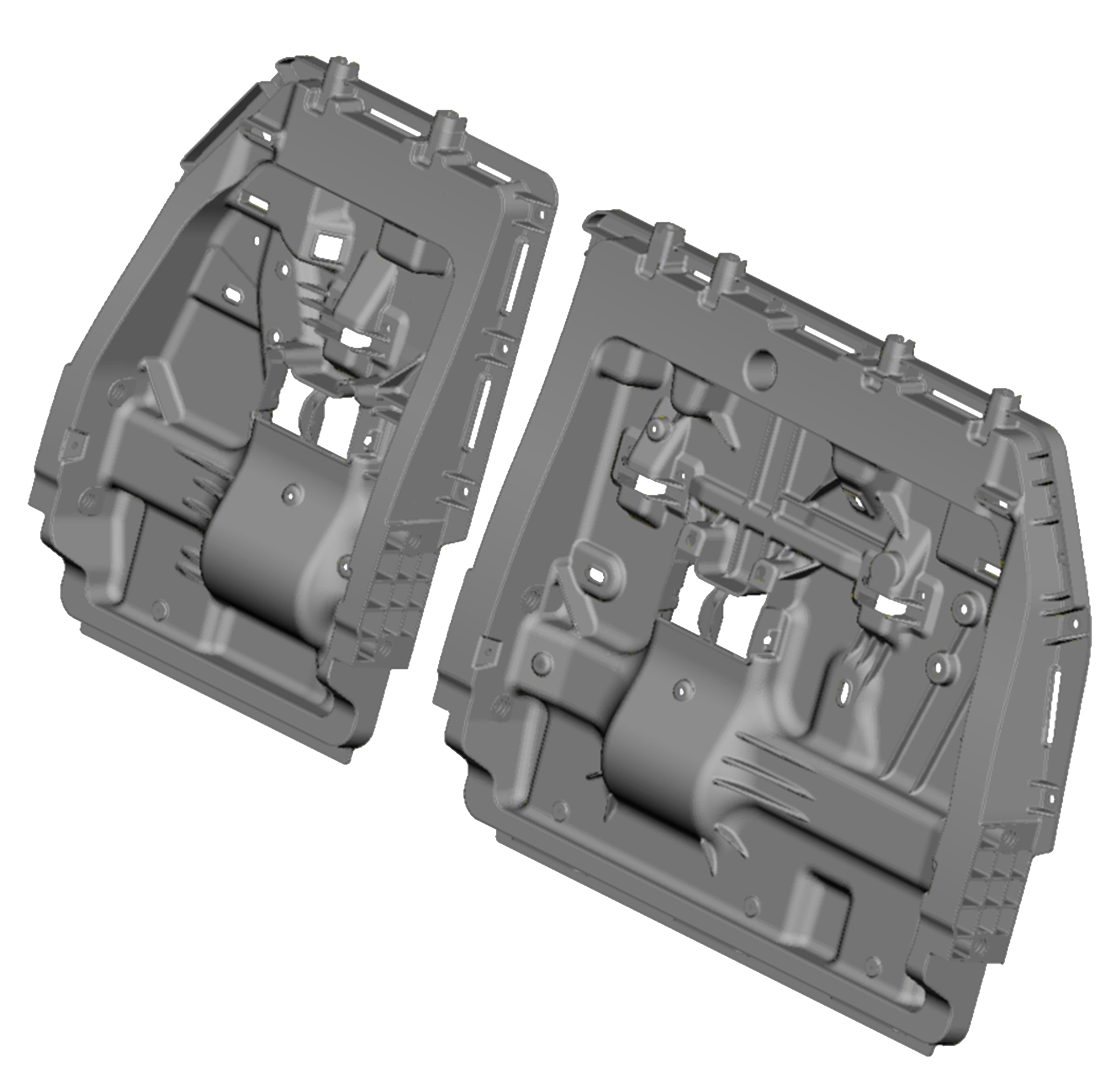

Traditionally, resin components for seating have had metal reinforcement, which can add more cost to the process, BASF said. Toyota also wanted an injection molding part made in one piece.. BASF supplied its Ultramid B3ZG7 CR 35% glass-reinforced and impact-modified PA6 grade, and its Ultrasim computer aided engineering (CAE) tool.

‘We were able to meet our cost objective and saved 15% compared to the prior generation,’ said Todd Muck, from the Toyota R&D Center in Michigan, USA. ‘The seat is 30% lighter compared to the previous model.’

‘One of the challenges was to ensure a high elongation and impact qualities for the crash requirements,’ said Matt Parkinson, manager at BASF Performance Materials. ‘At the same time, we focused on strength and stiffness because the seat also serves as a load floor.’

This story uses material from the BASF, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.