SGL Carbon says that it has received a multi-year order to make carbon fiber profiles for serial use in BMW model windshields.

The profiles, which will be supplied to auto manufacturing company Koller Kunststofftechnik GmbH, are made of flexible fiber tows pre-impregnated with thermoplastic resin in various dimensions. Production of the carbon fiber profiles will start in the remainder of 2020 and will then be ramped up gradually over the next few years, SGL said.

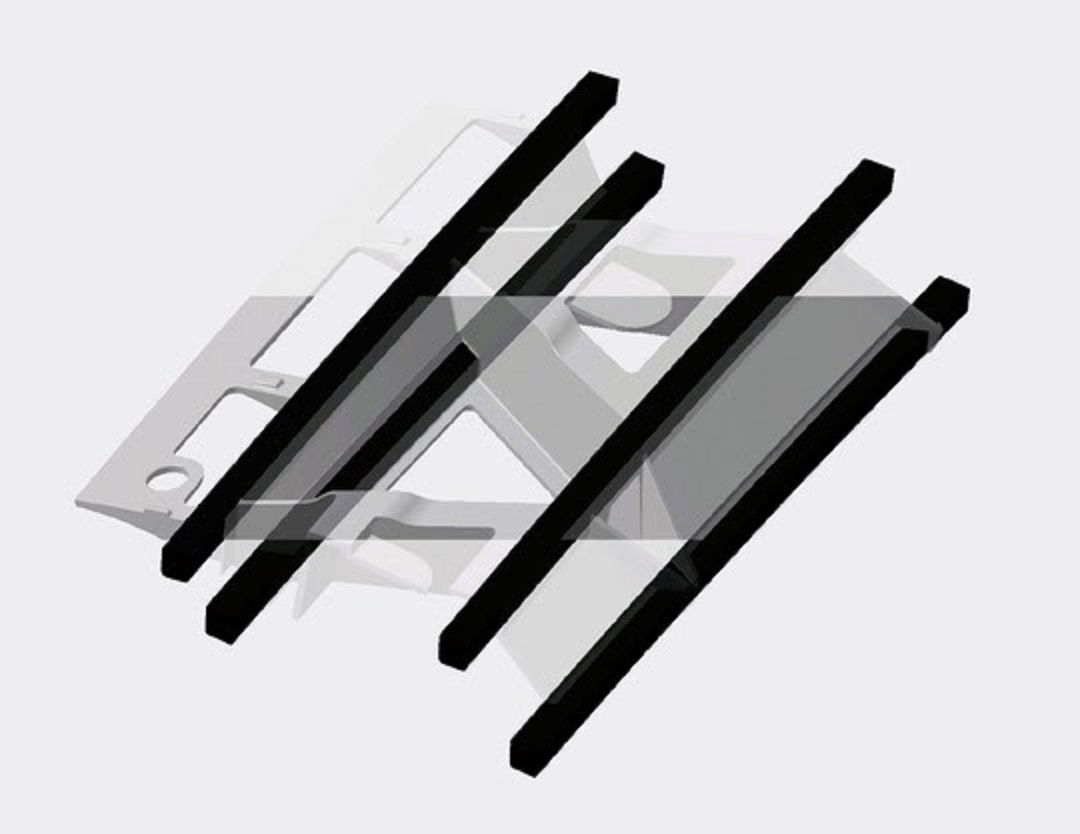

According SGL, the profiles will be formed by SGL Carbon using its 50k carbon fiber and then processed by the injection molding experts at Koller to form a skeletal plastic component, which can replace the previous steel-based windshield. The profiles consist of several smaller fiber strands (rods) and are manufactured using a continuous pultrusion process.

Carbon fiber profiles add stiffness and crash safety and can help reduce roof weight, according to the company. The injection molding process also enables more complex and material-efficient structures. In the BMW model, the component could reportedly cut weight by 40% compared to conventional steel designs.

‘At SGL Carbon, we have been working on the development of thermoplastic carbon fiber profiles for use in injection molding for some time already,’ said Sebastian Grasser, head of automotive at SGL Carbon. ‘Due to the many advantages and competitive costs, we see a great potential for the technology to be used in other automotive projects too.’

This story uses material from SGL, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.