Sicomin has supplied its epoxy resin for a new range of custom carbon fiber windsurf fins.

The company’s GreenPoxy 33 bio-based epoxy resin was used by windsurfing specialist Sonntag Fins products to help improve speed, fatigue performance and sustainability.

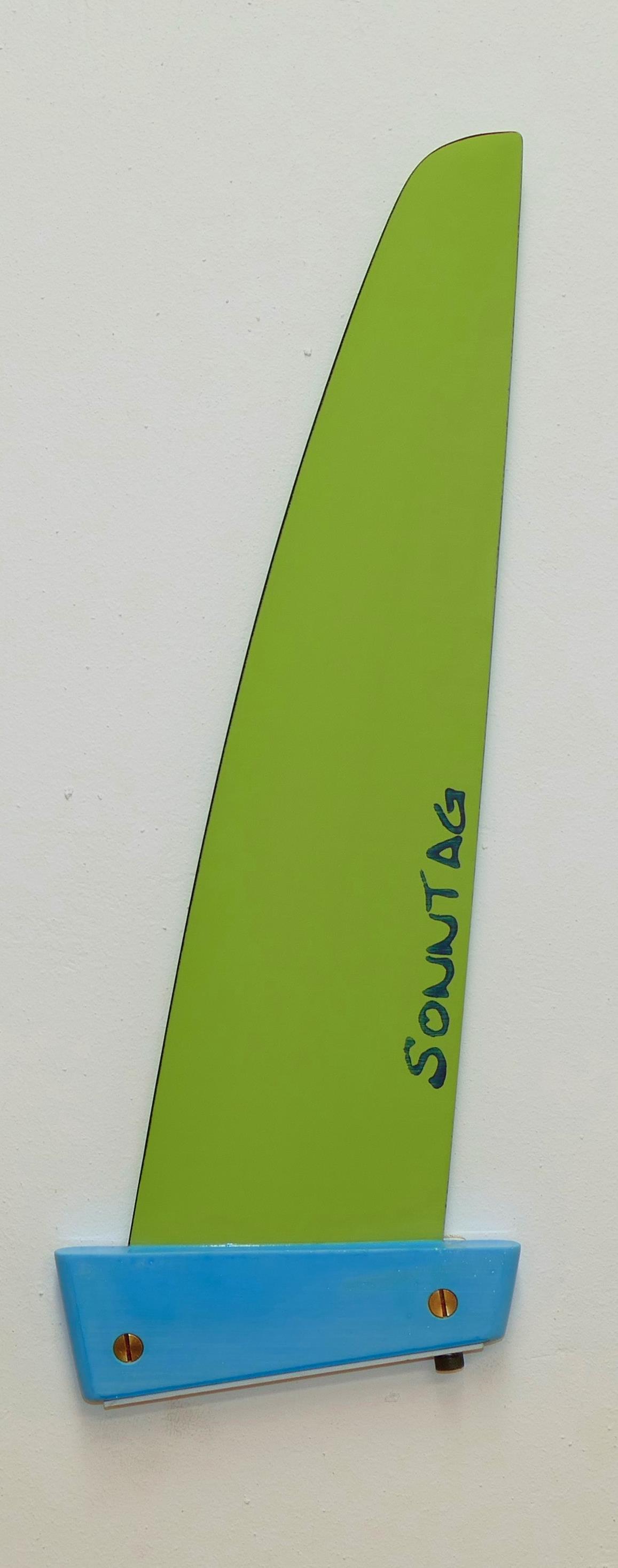

According to Sicomin, the fins are manufactured in CNC machined aluminium molds using GreenPoxy 33 resin and a bespoke lay-up of woven, stitched biaxial and heat-set unidirectional carbon fiber fabrics. This involves applying Sonntag’s green in-mold coating and placing individual fabric plies, cut using machined templates, into the mold which are then wet-out with low viscosity epoxy. This is next loaded into a heated press for around four hours to consolidate and cure the fin. After curing, the demolded fins are tempered in an oven at 140 °C, then sanded. Finally, the fins are cut to the required length and the base adapter is molded to the epoxy-carbon blade in a specific mold.

‘We produce high-performance windsurfing fins that need to accommodate significant loads during sailing,’ said Sonntag, MD, Sonntag Fins. ‘Fins need to combine flexibility with extremely high torsion stiffness that places high interlaminar shear forces on the resin, especially in our softer fins.’

This story uses material from Sicomin, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.