L&L Products has introduced a range of room temperature curing, high performance epoxy adhesives for aircraft interior applications that meet the latest FAA fire regulations (vertical burn, smoke density and toxicity).

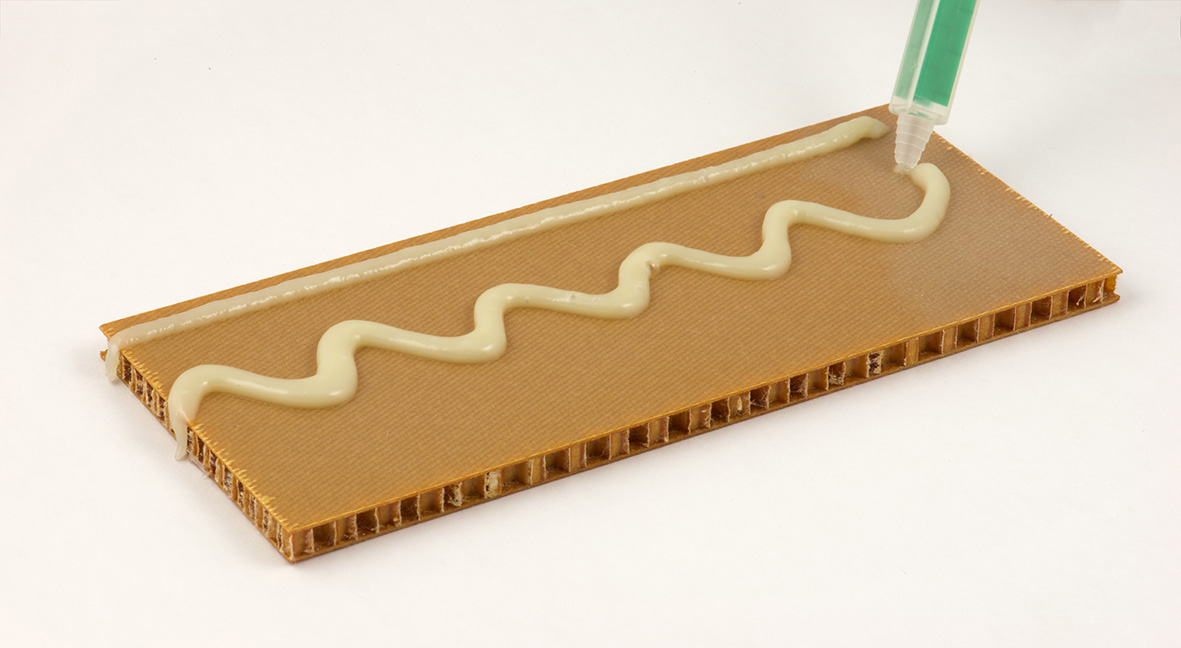

The new adhesives have a wide temperature range in terms of application and in-service conditions and can bond dissimilar materials. Typical applications include bonding inserts to honeycomb panels, panel to panel bonding, composite potting and fillet joints. Gel times are 5-90 minutes, depending on the material used.

The adhesives are available in two different open time versions: short (12 to 20 minutes) for immediate bonding and long (90 to 120 minutes) for larger parts. They can be supplied in 200 ml) twin-barrel cartridges, 20 liter pails or 200 liter drums.

This story uses material from L&L Products, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.