According to Gerber, field tests has shown that LaserKit enables composite cutting and kitting times to be reduced by as much as 40%.

GKN Aerospace Services Structures Corp, a manufacturer of structural composite parts for aerospace applications, has tested LaserKit.

“LaserKit reduced our overall cut and pick times by as much as 40% and lowered the possibility of operator error," reports Ray Lampron, Continuous Improvement Leader at GKN Aerospace Services Structures Corp.

"It also decreased training times since operators no longer have to ‘learn the bed.’ The software is easy to use so it’s practical even for short run jobs.”

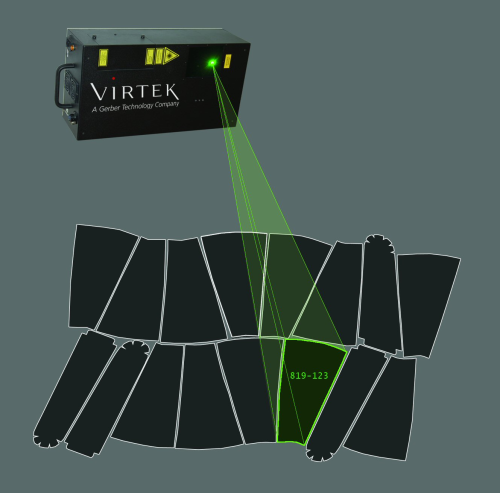

Virtek LaserKit uses a highly-visible laser to lead workers through the proper sequence of picking from the first ply to the last. The laser projects the outline as well as any identifying information on each ply. This eliminates the risk of errors that may occur during picking when similar plies are located in the same vicinity on the cutting table.

Available as an option to LaserKit is a lightweight printing device worn on a worker’s belt strap which prints labels automatically or on demand, accelerating the ply identification process. Labels can be affixed to individual plies or completed kits.

“With LaserKit, manufacturers can nest plies to achieve maximum composite material utilisation without having to consider how the cut plies will be picked," explains Todd Rhodes, executive director of Gerber’s Composites and Automation Solutions business.

"In fact, to maximise material utilisation, multiple kits can be nested together, cut and then picked from the same table. The LaserKit system directs workers on which plies to pick for each kit so workers can later lay up cut plies accurately and quickly on the tool. It’s critical in eliminating material waste and errors caused by incorrect ply order within a kit.”

Gerber Technology, headquartered in Tolland, Connecticut, USA, acquired Virtek Vision International, a provider of industrial laser solutions for manufacturers in the composites and aerospace industries, in 2008.