US Liner Company, Cranberry Township, Pennsylvania, USA, says that Bulitex woven thermoplastic composite sheet launched in 1999 offers a high impact, lightweight alternative to glass reinforced thermoset plastic (FRP), wood, steel and aluminium. It is now being re-launched and is available for delivery starting in July 2012.

US Liner’s line of composite materials includes:

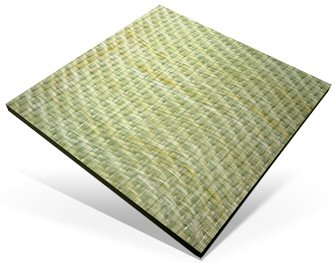

- Bulitex: fully woven layers;

- Bulitex Hybrid: woven/bi-directional combination layers;

- Versitex: fully bi-directional layers;

- Ecotex: recycled core with woven or bi-directional skins.

US Liner says Bulitex and Bulitex Hybrid can be mixed and matched with any of its other materials (Versitex and Eco-Tex) to meet performance requirements and budget needs.

All US Liner materials are available in a variety of thicknesses and widths up to 106 inches. It is normally supplied in bulk coils up to 1200 ft. It can be cut using a circular saw with carbide-tipped blade and can easily be sheared, routed or drilled for simple installation. Because the sheet is made from thermoplastic polypropylene, it can be formed into complex shapes or welded, with no loss of strength.

US Liner Company, a division of American Made LLC, supplies composite materials for the truck/trailer market, as well as the automotive, RV, rail and intermodal transportation, building products, and military sectors.