A University of Texas at Arlington professor is collaborating with Sikorsky Aircraft Corp using a US$1.35 million grant to design more durable materials and accelerate their uptake in composite aircraft.

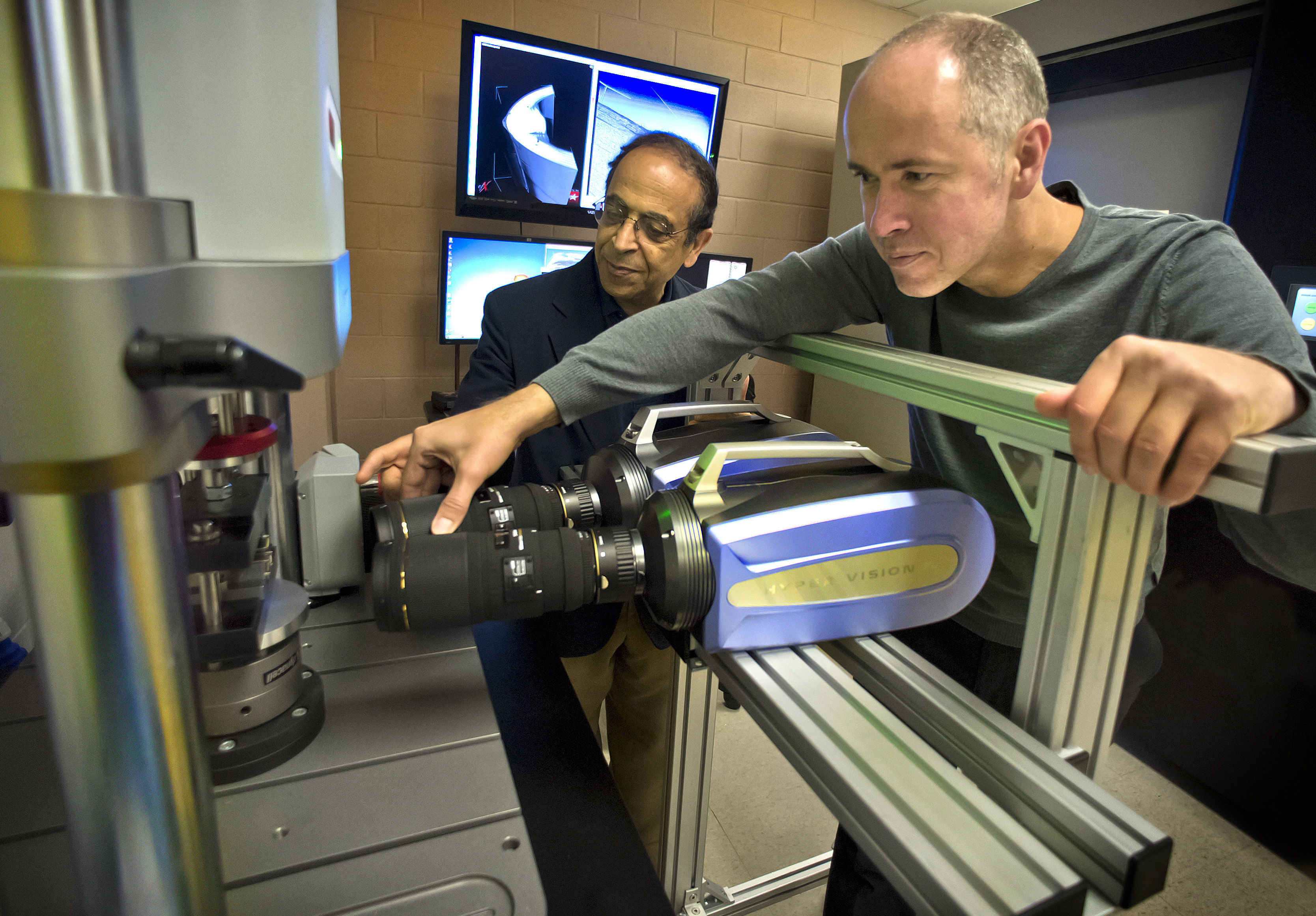

Andrew Makeev, professor in the mechanical and aerospace engineering department and director of the UT Arlington Advanced Materials and Structures Lab, received the grant from the Army National Rotorcraft Technology Center to build stronger and more durable composite materials for aircraft.

The program will build on the success of an existing project, the Vertical Lift Consortium (VLC) Advanced Material Technology Program to develop, test and characterize polymeric composite aircraft material applications. Makeev’s lab will continue working with material developers in developing laminate reinforcement methods and bonding solutions reducing weight and improving efficiency of vertical lift aircraft.

Makeev also will use heavy analysis to improve advanced material qualification methods to lower implementation costs for the new and improved material systems.

'This effort epitomizes our research mission to accelerate the implementation of composites through close collaboration with industry and government labs – a key to achieving cost-effective performance for the next generation of aircraft,’ said Makeev.

‘This project plays a key role in the implementation of composites in both commercial and military vertical lift aircraft,’ said Erian Armanios, chair of the mechanical and aerospace engineering department. ‘The benefits also will impact fixed-wing aircraft such as the Boeing's 787 Dreamliner which has 50% composites and Airbus A 350 with 53% composites.’

This story is reprinted from material from the University of Texas at Arlington, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.