TRB Lightweight Structures reports that it has produced and shipped 25,000 parts made from its proprietary, rapid-cure prepreg material.

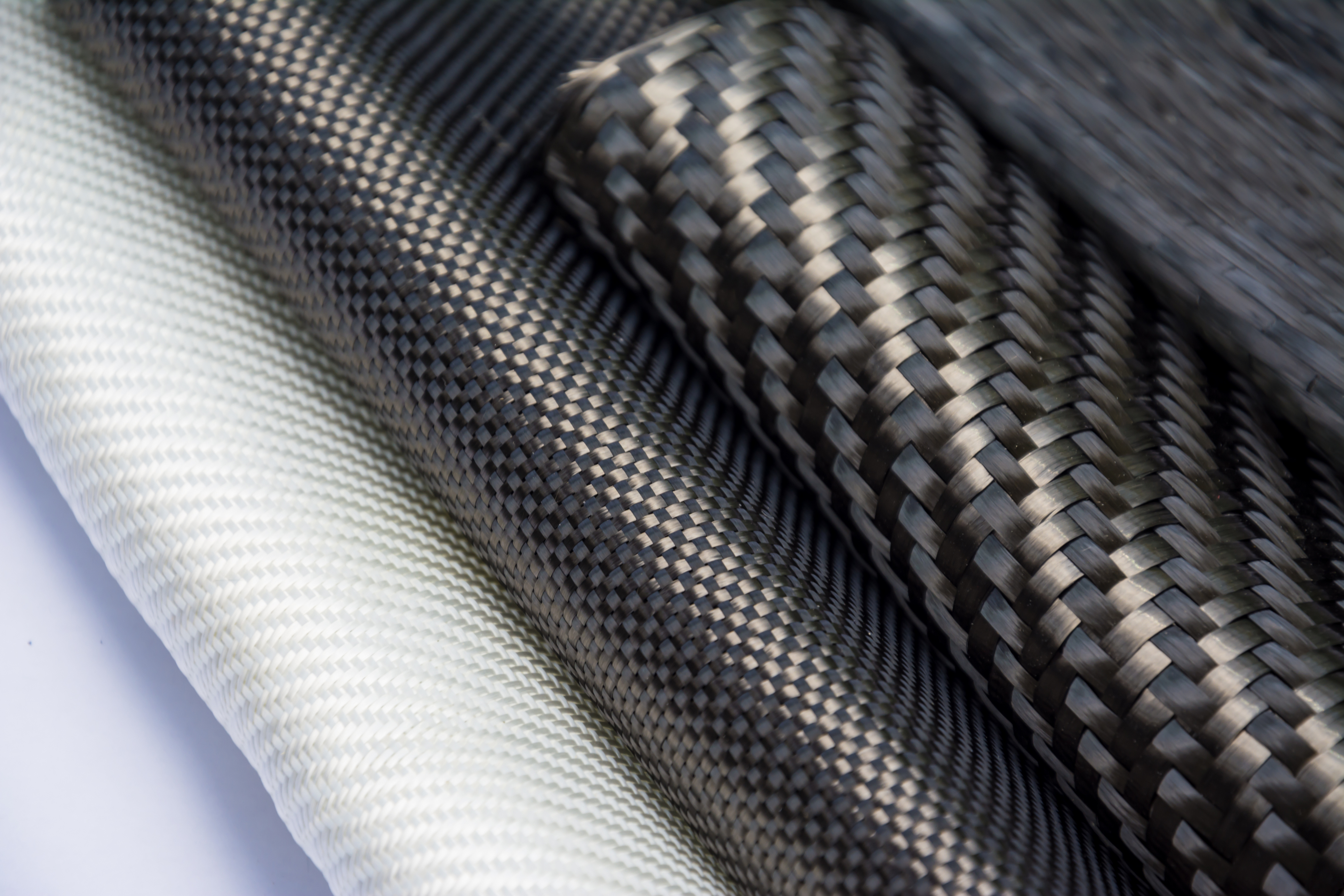

This follows the company’s announcement in late 2020 of new production process to produce continuous fiber thermoset composite parts at high volume for automotive markets. The company installed prepreg machines and is new developing a range of resins for component manufacturing, including resins optimised for rapid cure, FST (UL94-V0) and high temperature applications.

TRB says that it is currently not selling its prepreg commercially, but is focusing on streamlining its production process for the components it makes.

‘By making our own prepreg, we are able to tune the material selection to precisely match what is needed for each customer,’ said Andrew Dugmore, VP of business development. ‘We can create an optimal mix of fabric weight, coloured surface finish and resin properties, as well as incorporating additional materials – such as EMI shielding, and electrical and thermal insulation – during the lay-up process.’

This story uses material from TRB, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.