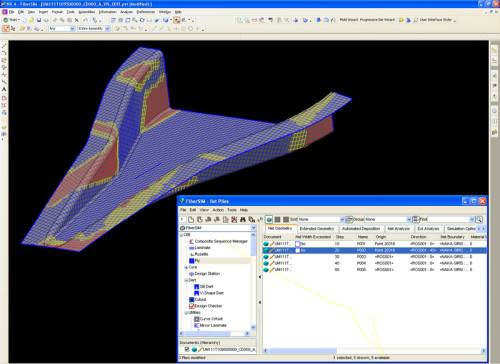

VISTAGY's FiberSIM composites software will be used to perform detailed part design, generate flat patterns, and compile and distribute manufacturing data and documentation for fuselage skins and frames, fairings, landing gear keel beam structures, wing and tail skins, spars and ribs.

This sale expands the use of FiberSIM within TAI, which is headquartered in Ankara, Turkey. TAI has previously used FiberSIM to design and manufacture composites parts for the Airbus A400M military transport aircraft and is currently using it on the development of the HÜRKUS primary and basic trainer aircraft secondary structures which are made of composites.

“The growing acceptance of UAS (unmanned aerial systems) aircraft to perform the 'dull, dirty and dangerous' missions in place of human pilots has resulted in a dramatic upsurge in their use,” says Chris Red, editor and vice president of market research for Composite Market Reports. “Approximately $1.5 billion was spent globally during 2008 on UAS aircraft and procurement is expected to grow 300% over the next decade. Production of related advanced composites are expected to grow at an even faster rate.”

“VISTAGY’s experience and expertise in composite design methodologies was a key factor in our decision to purchase FiberSIM for our UAV programme,” says Dr Gursel Erarslanoglu, manager of structure engineering for TAI’s Integrated Aircraft Systems Group. “FiberSIM enables us to design composite parts and transfer manufacturing data to the factory floor in a fast and reliable way, thanks to its user-friendly interface.”

VISTAGY Inc is headquartered in Waltham, Massachusetts, USA.