SP, the marine business of Gurit, believes that the hull for Panamax is the largest ‘one-piece’ prepreg moulding that has ever been produced.

“Panamax has been our biggest project to date" says Rod Fogg, principal engineer at SP, Isle of Wight, UK. "The sheer scale of the yacht creates constant challenges for everyone involved, but its ground-breaking systems and engineering mean that it is not just another large sailing yacht.”

“One of the biggest challenges of the structural design has been the two-stage lifting keel, which can operate in three positions, but raises in two stages using internal and external rams to 3.7 m above the deck for the harbour draught," he adds. "Designing for an ultimate grounding load of some 3000 tonnes means this could also be one of the highest point loads ever in composite design. To help with the flow of such construction information, SP has had an engineer on-site for a year.”

Other key features of the vessel include a light-ship displacement of just 210 tonnes, revolutionary drive-train and power-generating systems and 40 tonnes of water ballasting.

The Panamax yacht is currently under construction at the Finnish yard of Baltic Yachts, which is well known for delivering high-performance sailing yachts, and will be delivered in 2011. It is being constructed using principally a combination of SP prepregs, Nomex™ honeycomb and Corecell™ foam cores.

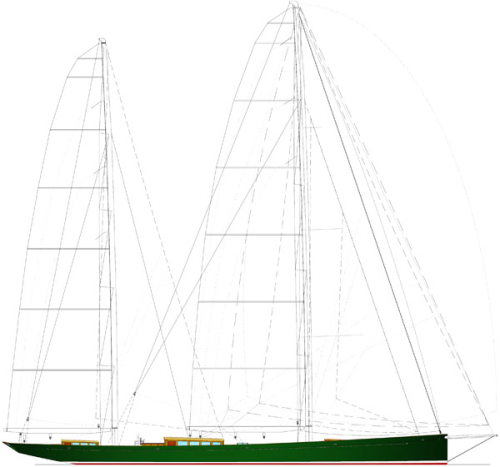

The vessel has been co-designed by two naval architecture offices – Gerard Dijkstra & Partners of the Netherlands and Reichel Pugh Yacht Design Inc in the USA.

One of the owner’s stipulations was that, despite the size of the vessel and the fact that it will be carrying the world's largest composite standing rigging, it should still be able to pass safely through the Panama Canal – hence the name Panamax.