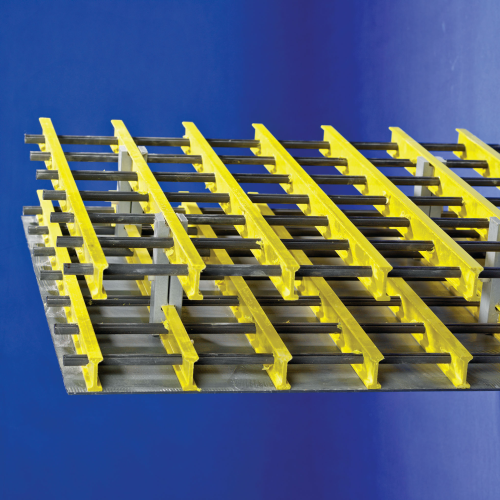

Strongwell’s GRIDFORM (see picture) consists of two layers of pultruded fibre reinforced plastic (FRP) I-bar grating separated by FRP connectors with nylon bolts. A pultruded FRP plate is bonded to the bottom grating layer to create a stay-in-place (SIP) concrete form.

This system creates a lightweight panel for the grid construction of concrete bridge decks. The GRIDFORM panel, which weighs only 4.7 lb/ft2, is shop-fabricated in very large units that are limited only by shipping constraints to approximately 50 ft by 8 ft.

Degradation of the typical steel reinforcement in concrete bridges is caused by corrosion due to deicing salts and harsh environments. According to Strongwell, the anticipated lifespan of a GRIDFORM bridge deck is several times that of steel reinforced concrete bridge decks since FRP provides a corrosion-free reinforcement system for the concrete.

The amount of labour required to create formwork and tie in rebar associated with typical steel reinforced concrete decks is eliminated with GRIDFORM. The large prefabricated panels can be lifted and set with a single pick of a crane, providing significant reduction in construction time of the bridge deck.

The Strongwell GRIDFORM Design Guide was been developed with the help of the University of Wisconsin-Madison School of Engineering.

Engineers can enter the specific load requirements and properties for a bridge and the guide will provide design results for a GRIDFORM reinforced bridge deck.

The GRIDFORM Design Guide can be downloaded from the Strongwell website.

Headquartered in Bristol, Virginia, USA, Strongwell is a leading pultruder of FRP composites.